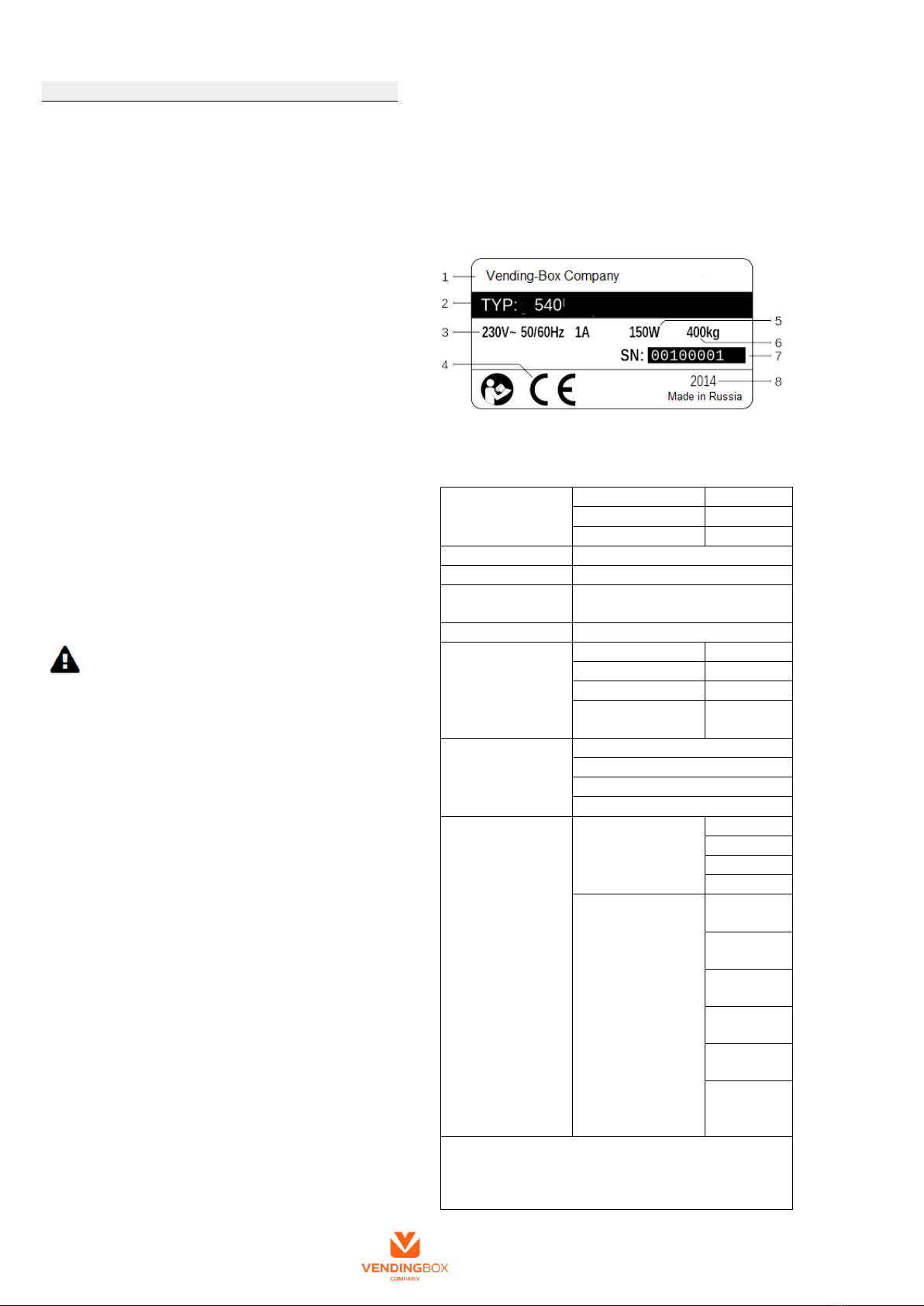

Vending-Box COMPANY Model 540

The device together with its package should undergo

recycling.

Illegal utilization is the subject to penalties.

European Union countries

Devices marked with this symbol should not be utilized

together with municipal waste. More information may

be obtained from the producer.

Non-European Union countries

The owner of the device should contact local authorities

in order to obtain information on the appropriate

utilization.

INSTALLATION OF THE DEVICE

9Location of the machine

The machine is not intended to be used outdoor. It must

be located in a dry indoor place and it must not be

moisturized by any water or other liquid drops. If the

machine is equipped with radio communication

systems, all metal objects must be placed in the distance

of at least 1 metre from the machine.

10 First start-up

Before the first start-up, it is obligatory to get familiar

with this manual. If the information included in it is not

precise enough, please contact the producer’s service.

All procedures described in this chapter should

be done with the machine disconnected from the

power supply.

Before starting up the device, you must check technical

condition of the machine, if it has not been damaged

mechanically in transport. In case you find any damage,

it must be assessed if it affects safety and if it might

limit the functioning of the device. If so, any starting-up

procedures should be stopped.

If you are not able to define the device

condition or you have no qualification to assess

if the damage might cause any danger to the

user, contact an authorized

First thing to be done after placing the machine in its

final destination is to level it with the help of four

levelling feet, which are supplied with the device. While

placing the machine vertically, use an appropriate lift.

Do not lift the device with the use of the levelling feet.

Next step is regulation of the left and right door hinges,

which could be moved in transport. To do it, you

should use upper hinges fixed with tree screws each,

two from the top and one accessible from the inside of

the machine. To get access to the inner screws, you

must open the device.

Hinge screws should be only loosened and after

regulating the hinge, they should be screwed so that the

hinge could not be moved during opening the door.

After regulation, the space between the doors should not

be bigger than 3 mm, equal along the door edges. The

outer edges of the doors should fit the contour of the

shell of the machine. After the right door is blocked,

you must check if the sensor of the left door opening

switches after it is closed. You should hear a clear click

of the sensor pins. If after closing the door, the switch is

not on, you must move the tappet of the door sensor

located on the left door so that the sensor is clearly

switched on after the door is closed.

The door opening sensor is one of the elements

responsible for safe work of the machine. In

case it is not switched on after closing the left door,

feeder rotation will not be possible.

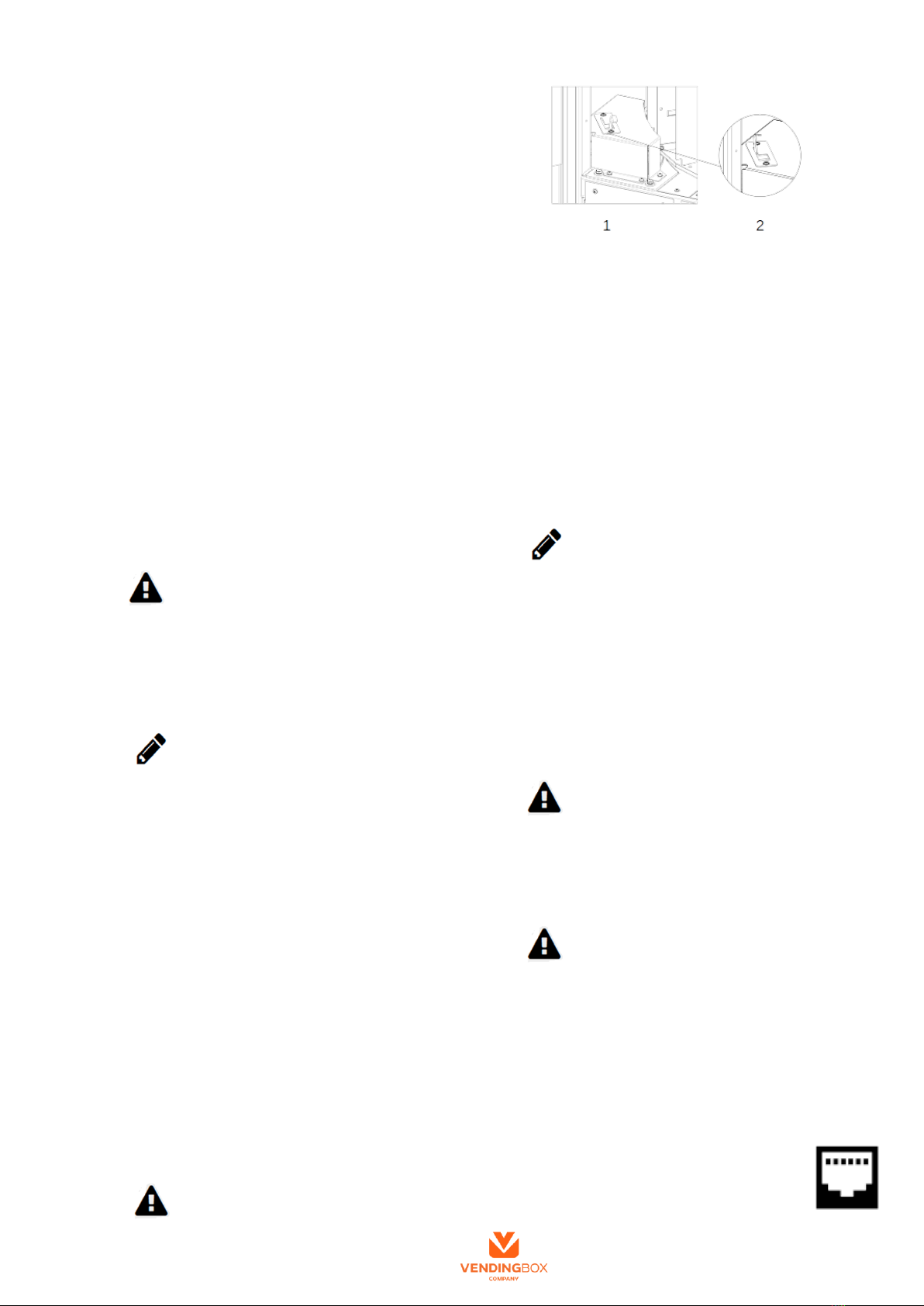

The last thing which should be done before starting up

the device is verification of the free feeder rotation. To

do it, you must unlock the drum by pulling the brake rod

away from the feeder and pushing it away from you so

that the rod gets blocked in the gap of the brake shell. In

the picture you can see the view of the brake in the

position blocking the rotation of the feeder (1) and in

the position of the blocking mechanism pulled in (2).

After unlocking the drum, the feeder may be rotated

manually. Give the drum a full turn checking if the

movement is free and no alarming noises come out of

the machine which could mean that the drive

mechanism might be damaged. If you notice

inappropriate work of the feeder, stop the device

starting-up.

If you are not able to define clearly the state of

the feeder’s work, contact an authorized service.

If the condition of the machine is verified, the device is

leveled, door suspension is regulated and the feeder

rotates freely, the machine is ready to be started. More

information on this subject can be found in the chapter:

Starting the device.

11 Starting the device

If the device has been transported or has not worked for

a longer time, follow the procedure described in the

chapter: First Start-up.

In order to start the device, first you must plug it in the

power supply. Connecting the machine with the power

supply of 230VAC should be done when the

main switch is in the 0 position.

The connected device must be laced behind the

ground-fault circuit and the power socket must enable

connection with PE conductor.

After connecting the machine with the power supply

and switching on the machine with the main switch

(position 1), the device will be started.

Switching on the power supply, with the

opening door sensor turned on causes automatic

rotation of the drum in order to set its position.

Remember not to leave protruding elements in the

feeder and to move aside from the feeder after switching

the machine on.

After a short while, the display shows start-up screen

with description of the model of the machine and a

variety of status icons informing about the state of

starting-up.

11.1 ETHERNET

The first one to be started is the

ETHERNET interface. This showed icon

informs about the connection with the net. If

the connection is successful, the icon color

will change from gray to blue.