Contents

MVHR Installation and User Guide 476930 3

Operation and Monitoring 4

Product Description......................................................................4

Accessories................................................................................42

Controlling the unit.......................................................................5

Touch screen display...................................................................5

Control via WiFi............................................................................5

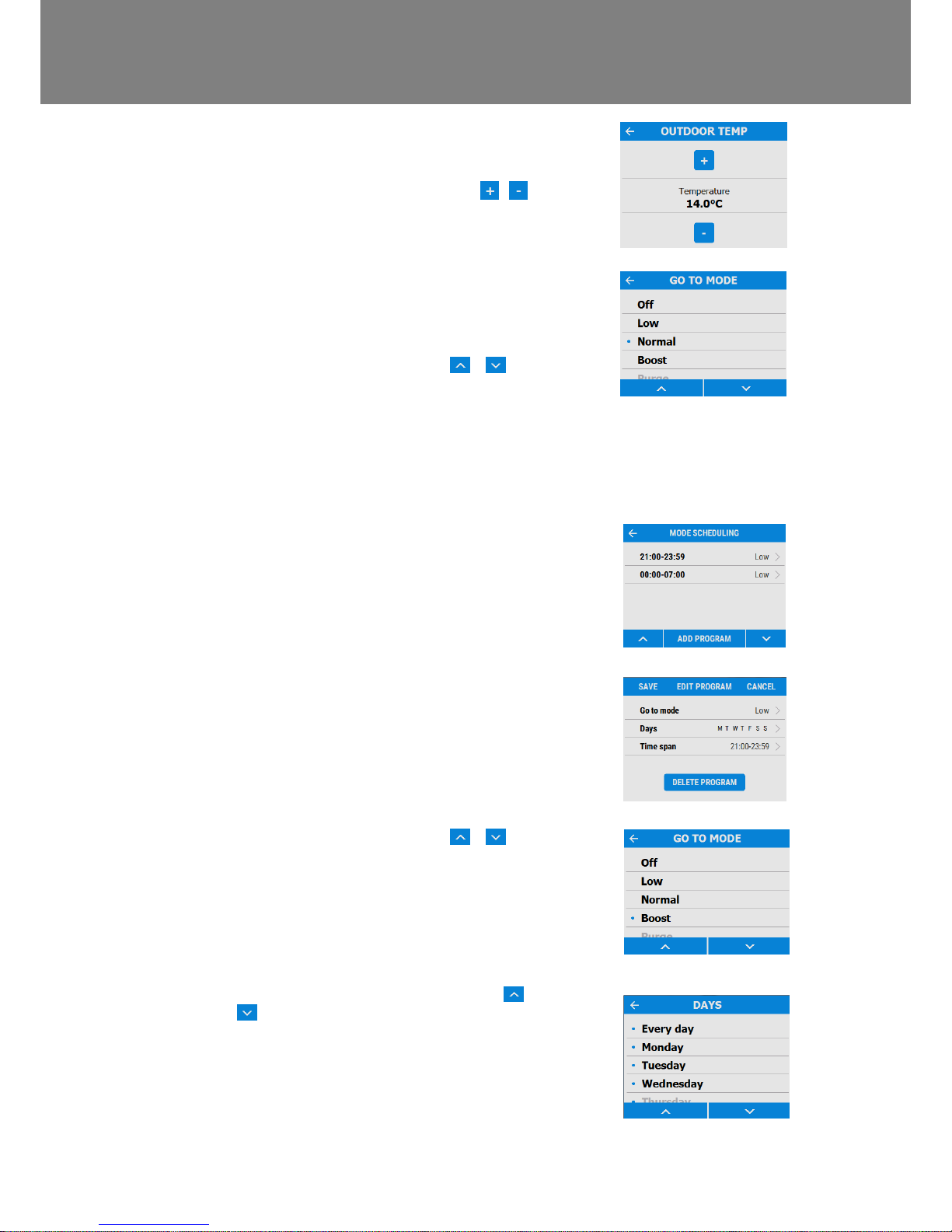

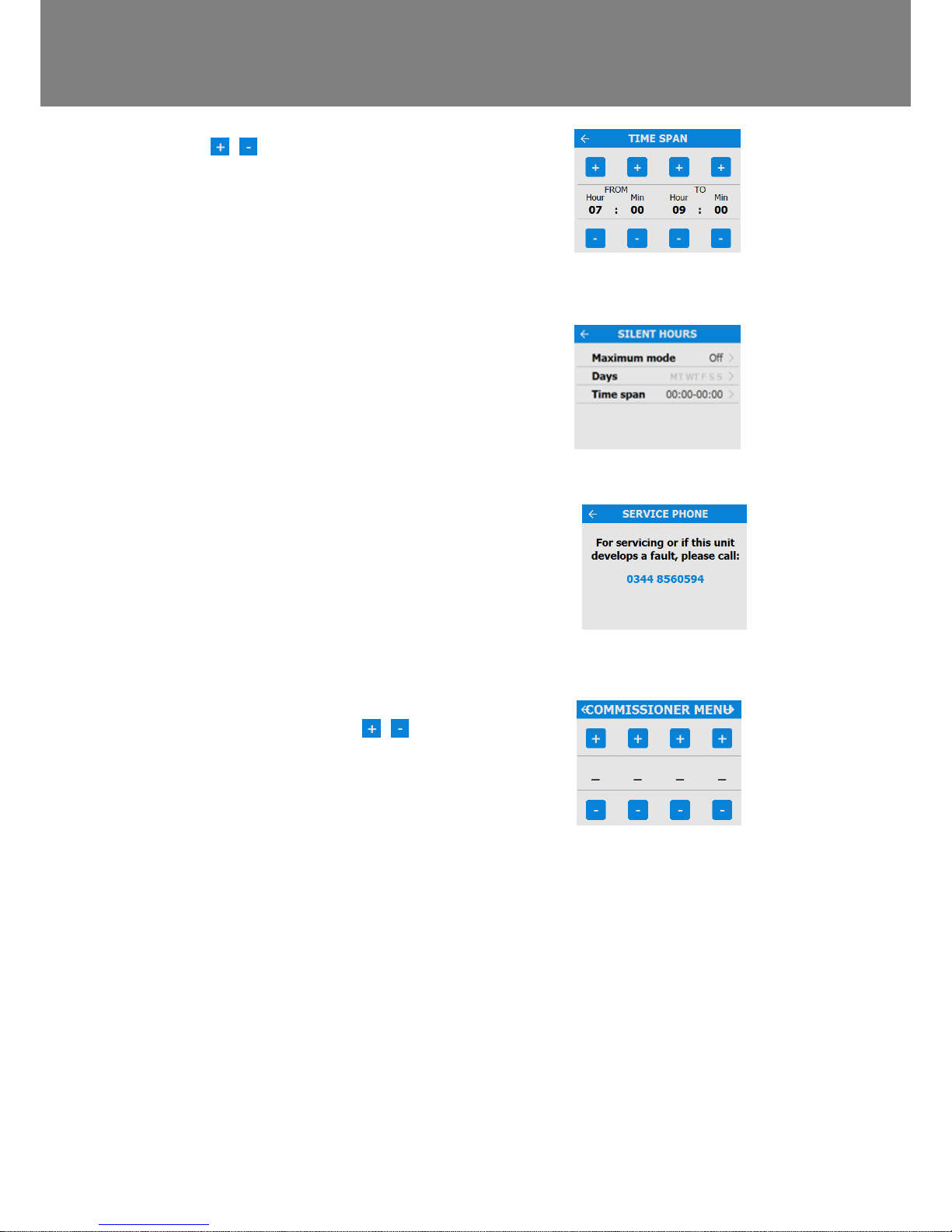

User controls................................................................................6

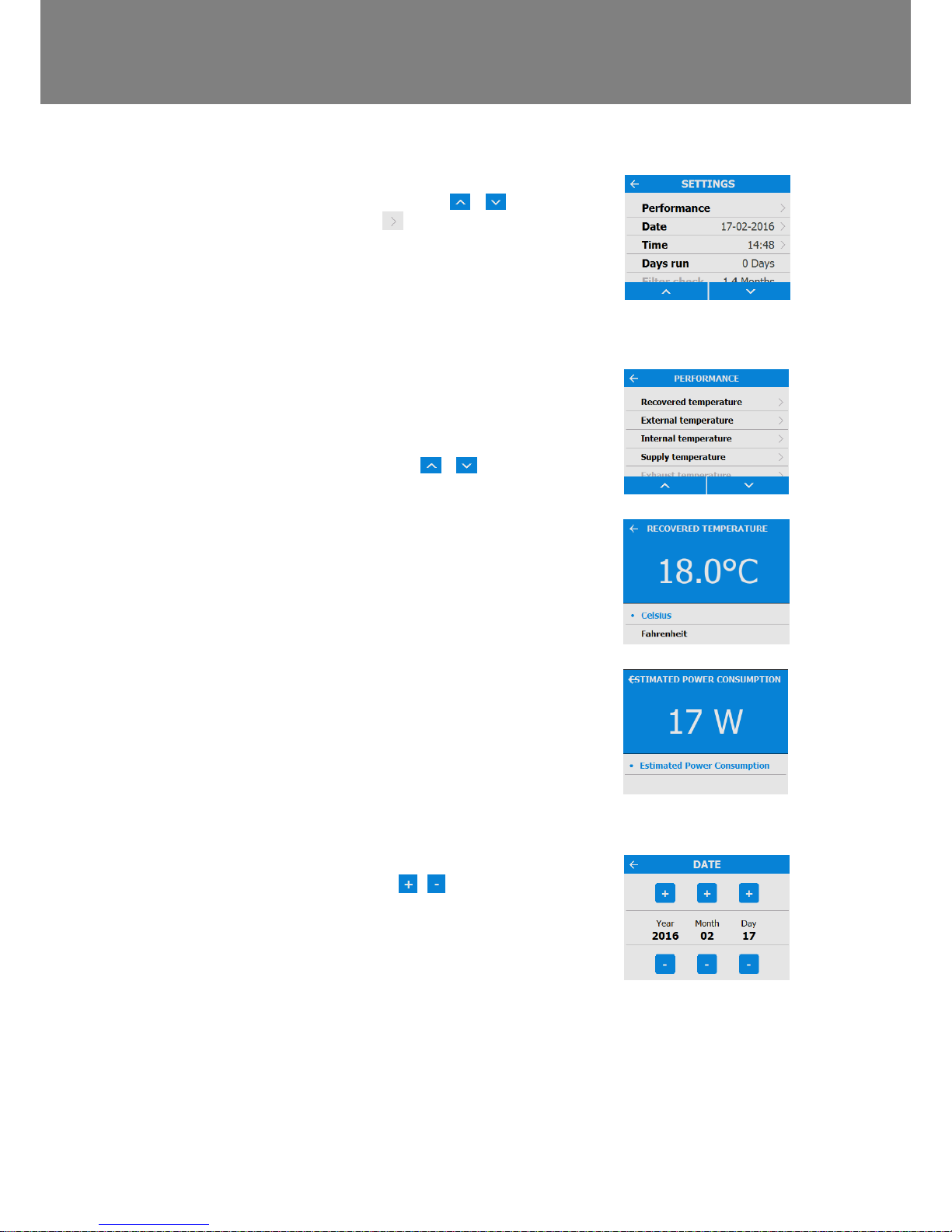

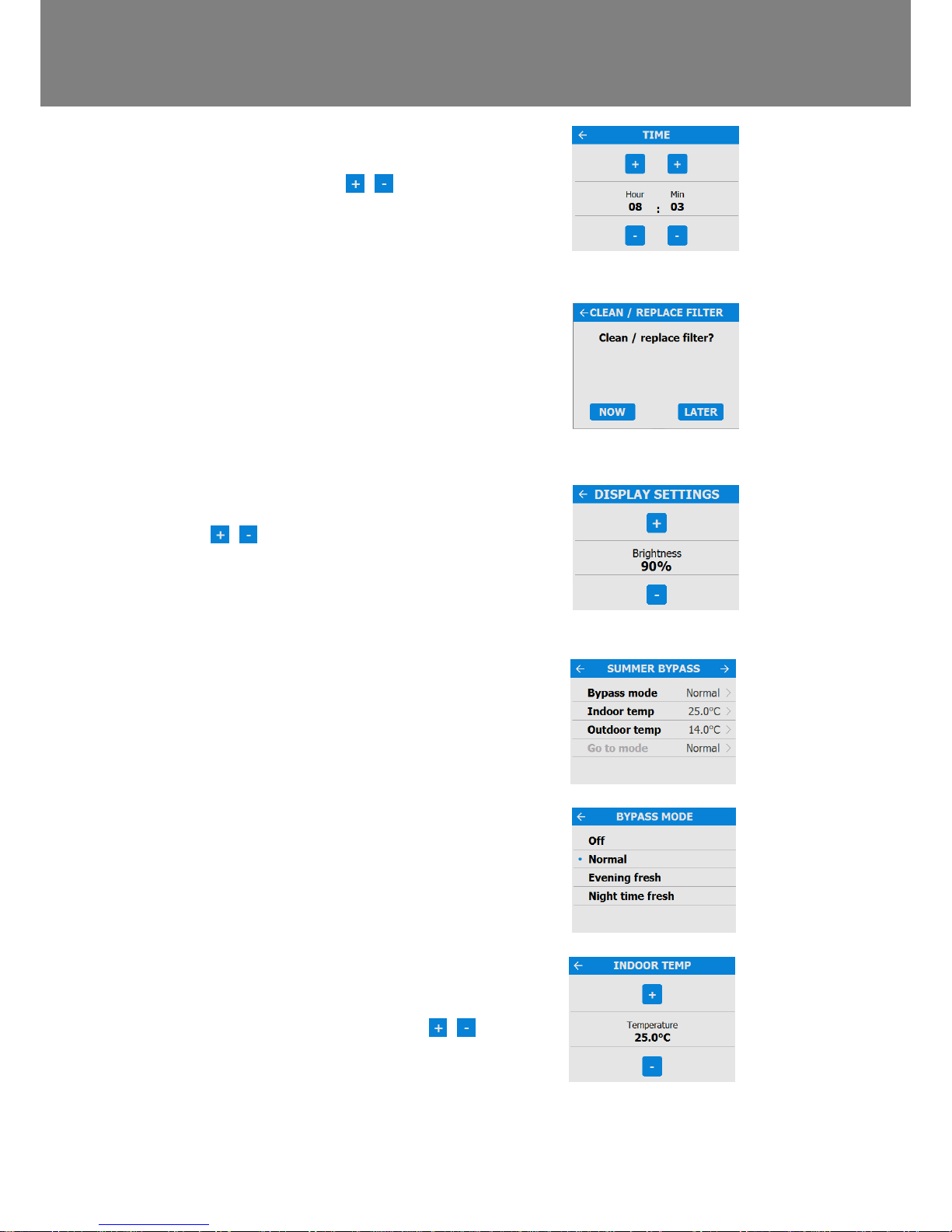

Settings and Performance............................................................7

Control Unit Screens Summary..................................................12

Control Unit Screens Summary..................................................13

Maintenance 14

Filter Maintenance......................................................................14

Periodic Maintenance.................................................................15

Spares .......................................................................................16

Troubleshooting 17

Diagnosing a Problem................................................................17

Installation 18

Overview....................................................................................18

Wall Mounting the Unit...............................................................19

Floor Mounting the Unit..............................................................20

Floor Mounting the Unit (Alternate Method)................................21

Vertical Discharge Condensate Installation ................................22

Attach the Ducting......................................................................23

Electrical Installation ..................................................................24

Connect Switches and Sensors..................................................25

Connect the Power Supply.........................................................27

Commissioning 28

Powering up the Unit..................................................................28

Overview....................................................................................28

Control Unit Touch Screen Display.............................................28

Modifying Settings......................................................................29

Commissioning Screens Summary.............................................30

Modifying Commissioning Settings.............................................32

Commissioning the Unit via USB................................................41

Accessories 42

WiFi Controller...........................................................................42

Ventwise Accessory...................................................................46

Input Switch Accessory..............................................................50

Switched Live Expansion PCB Accessory..................................52

Analogue Input PCB Accessory .................................................54

Wired Remote docking Kit Accessory.........................................56

Technical data 58

Flow Rate settings......................................................................58

Frost Protection..........................................................................58

Summer Bypass Mode...............................................................59

Product Dimensions...................................................................60

Spares .......................................................................................61

Default settings..........................................................................62

Disposal.....................................................................................64