Venture Industries ROOF-H User manual

OPERATION AND MONTAGE MANUAL NO.:

ROOF-H-2021-V1

(

valid since:

14.10.2021)

Venture Industries Sp. z o.o. is not responsible for any damage caused by improper use of the fan and reserves the right to modify this

document without informing the user.

OPERATION AND ASSEMBLY MANUAL

OF ROOF FANS TYPE ROOF-H

Roof fans type ROOF-H

2/11 tel. + 48 22 751 95 50 www.ventur.eu fax. +48 22 751 22 59

INTRODUCTION

This manual covers fan listed on front page. It is source of information necessary for safe and proper use. Read this manual

carefully before any use of the device, comply with it requirements and keep it in place with easy access for users and service. If

case of any doubts about use of the fan, please contact with manufacturer.

After receiving the device - check

• whether the device is in compliance with order,

• whether the data on the rating plate are the same as desired (voltage, frequency, etc.)

• whether fan was not damaged during transport (e.g. there are no dents/cracks, impeller rotates freely)

• whether motor documentation (including operation manual) has been attached to the fan

In case of any irregularities, contact with your dealer or Venture Industries Sp. z o.o. service.

1. GENERAL INFORMATION

1.1 Information about device

•The fan is a not completed machine within the meaning of the Machinery Directive 2006/42/WE (please refer to the manufacturer's

declaration –Appendix E).

•Fan is designed for use by trained, qualified adult persons in industrial environment.

•The device is designed to transport clean air and air with dust - required contact with manufacturer. Do not transport the explosive

mixtures, solid elements, liquids, substances that cause abrasion, chemically reactive compounds. Minimal temperature of transported

medium is -20°C, maximum is determined on rating plate.

•Protect the fan against protect the fan from lightning. The unit is designed for outdoor installation. The fan's environment must not contain

explosive mixtures, abrasive substances, chemically aggressive compounds, sticky substances or substances with high humidity. The maximum

ambient temperature is indicated on the nameplate, the minimum is -20°C. The device is not designed for operation in hot smoke

environment.

•The device must not be exposed to radiation (such as microwave, UV, laser, x-ray).

•The impeller of the fan has been balanced in conformity with minimum G6.3 class, according to ISO 1940-1, and entire fan with cat. BV-3

according to ISO 14694

•Details of fan construction have been included in appendix A

•Additional information on usage of the fan have been indicated on the device as markings. More information is introduced on appendix B.

1.2 General risk and guidelines

During entire fan life cycle pay particular attention to the risk and guidelines presented below:

1.2.1 Moveable components

•The fan is equipped with moveable components (impeller of the device, impeller of the motor). Contact with them may cause

serious injury or death. The fan must not be used if covers (grids) and safety measures against contact with rotating parts have

not been installed.

1.2.2 Suction

•The fan has high suction power. Clothing, hair, foreign particles, and even body elements can be easily sucked in. It is forbidden to approach

the fan in “loose” clothing or reaching toward inlet of working fan and motor impeller. It need to be ensured, that no foreign body can be

sucked in.

1.2.3 Thrown elements

•The air at the outlet of the fan has high energy. Elements sucked or placed inside the fan can be thrown with a high speed. The fan has

stable, solid construction, but as a result of damage or improper use some parts (elements with high kinetic energy) may be thrown away.

Make sure that before start and during operation of the fan there are no elements, that may be sucked in (pay special attention to fan inlet

side) and there are no person in stream of transported medium (on inlet and outlet side). Do not use fan without proper inlet, outlet covers

(grids).

1.2.4 Sharp edges

•During manufacturing the fan sharp edges was grinded. However the fan may have edges touching which may cause injury.

We recommend the use of relevant protective gloves.

1.2.5. Inertness

•The fan has a high inertness. In case of no permanent fix turning on the fan will lead to it uncontrolled movement. The unit can be turn on

only after proper installation.

1.2.6 Noise

•The sound pressure level is dependent on the operation point. Check the sound pressure level and if necessary use silencers

and/or individual protection measures for personnel. Sound pressure level generated by the fan is on www.venture.pl.

1.2.7 Materials

•In case of fire or transport of improper medium –fan parts can generate fumes hazardous to health.

1.2.8. Environment

•The fan can make over and under pressure. In areas where a specified air pressure and the quantity of air are required (e.g. in places with

combustion) make sure that there would be no deficit/excess of air.

1.2.9 Temperature (hot surfaces)

•The housing and fan elements take the temperature of transported medium. During work (e.g. as a result of compression

process) the temperature of medium, housing and fan components increase. Electric motor heat up to high temperatures

(especially when overloaded/overheated). The appropriate steps need to be made to prevent from fire and burns caused of

high temperatures. In case of fire –to extinguish a fire use fire extinguisher approved for electrical equipment and follow

recommendation of fire department.

1.2.10 Unexpected start / connecting power supply

Roof fans type ROOF-H

tel. +48 22 751 95 50 www.ventur.eu fax. +48 22 751 22 59 3/11

●Before undertaking any kind of work on fan (e.g. installation, maintenance and inspection, disassembly), it has to be

completely and reliably disconnected (isolated) from power supply (check there is no voltage). It has to be ensured, that power

supply will not be connected during work on fan and moveable parts are not moving.

•The fan has stable, solid construction, but as a result of damage or improper use some parts (elements with high kinetic energy) may be

thrown away. In case of impropper protection there is risk of sucking foreignt elements into the fan. Risk arising from damaging electrical

wires placed inside fan / air stream - e.g. using appriopriate construction grounding and security device in fan supply line.

•Capacitor (only single phase fans) is still energized for certain period of time after turning off the power supply.

•The appropriate steps need to be made in order to provide protection against electric shock and to prevent from access to electrical

components by unauthorized person.

● Fan is not equipped with control system – the connecting of power supply causes immediate start-up. The device is not

equipped with system, that would permanently shut it down in case of temporary power supply loss. It has to be ensured, that

any dangerous or unpermitted event does not occur in case of temporary loss of power supply.

•Thermal sensors installed in motor (if fitted) after tripping caused by motor overheat turn back to initial state after cooling down. It has to be

ensured, that any dangerous or unpermitted event does not occur in case of action of thermal sensors and after motor cooling down.

● In case of impeller jamming – its unblocking may cause sudden movement. Appropriate steps need to be made in order to avoid impeller

jamming. In case of impeller jamming, fan need to be completely disconnected from power supply and repaired.

● After disconnecting from power supply fan still works for certain time (moveable parts are moving) as a result of energy accumulation.

1.2.11 Use

•Improper installation and/or use may lead to damage of the device and occurrence of dangerous situation. The unit can by installed,

maintained, dismantled and used only by qualified and authorized personnel, in accordance to safety rules and current regulations in the

country of use (including proper electrical authorization). Personnel need to be familiar with reactions caused by the fan.

•Using of fan in dismantled/uncompleted state is forbidden, e.g. without junction box cover, revision cover.

•During the works (e.g. maintenance, installation) the fans surrounding needt to be protected from bystanders approach.

•Any modifications of the unit are forbidden. Complicated maintenance work (such as dismantling the motor or impeller) need to be made by

Venture Industries Sp. z o.o. service or with it permission - according to additional guidance. Improper assembly may lead to reduce the fan

parameters, damage the unit and lead to the dangerous situation.

1.2.12 Accumulation of dust

•Prevent the accumulation of dust, sediment on and inside the fan. Dirt accumulated on: grids –reduce the fan parameters; impeller –may

lose it balance; housing and motor –can reduce the cooling; hot surfaces (see 1.2.9) –may ignite.

1.2.13 Explosive atmospheres

•Contact of the fan with explosive atmospheres cause in ignition. It is forbidden to contact the fan with explosive atmospheres.

2. TRANSPORT AND STORAGE

2.1 Transport and storage guidelines

•The fan need to be transported and stored in original packaging, without excessive shocks. The device must be protected from weather

conditions, transported and stored in dry, well ventilated, and free from substances harmful to the device areas. The fan cannot by

transported and stored in areas with fertilizers, chlorinated lime, acids and other aggressive chemicals. Fan need to be protected against

foreign body entrance.

•Protect the fan against damage (including crush). After lifting unit it need to be put slowly.

•Do not lift the unit by impeller, motor elements. During lifting the device must remain stable.

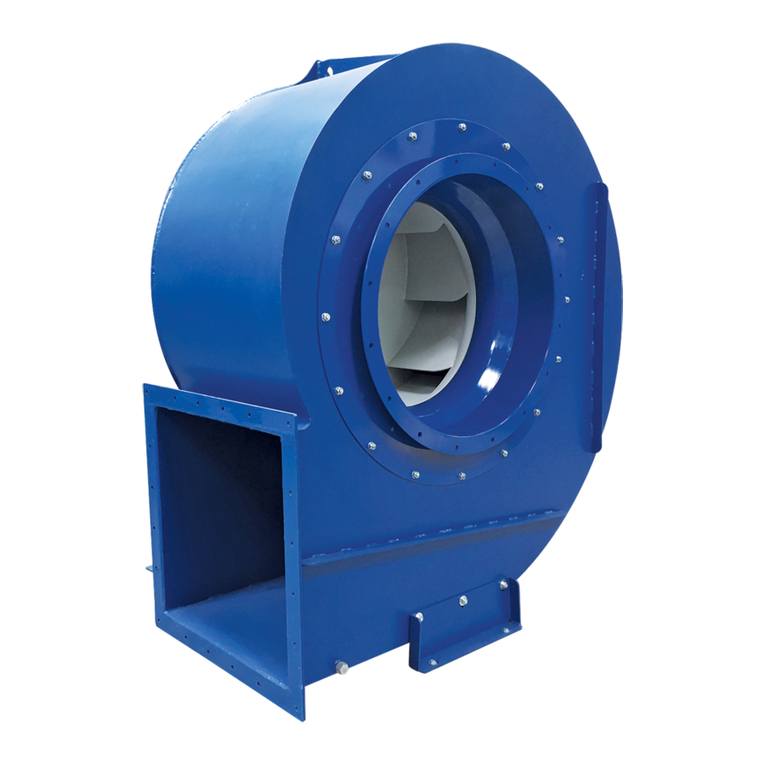

•The fans should be lifted by the structural elements provided for this (according to Fig. 1).

Fig. 1

•Do not approach lifted device. In case of breaking, falling device may cause serious injury or death.

•It is recommended, that the storage period of the device does not exceed one year. After long storage, the condition of the fan must be

checked before installation (chapter 5). During storage, the impeller of the device should be turned by hand (minimum 3 rotations) at least

once a month.

Roof fans type ROOF-H

4/11 tel. + 48 22 751 95 50 www.ventur.eu fax. +48 22 751 22 59

3. ASSEMBLY AND INSTALLATION

3.1 General information

•During installation follow the guidelines contained in section 1.2

•The fan is a machine not ready for use (within the meaning of the Machinery Directive 2006/42/WE - before use of the device ensure

conformity with requirements of Machinery Directive 2006/42/WE. After installation the device must meet the requirements included in EN

ISO 12100, EN ISO 13857, EN ISO 13850 and EN 60204-1 standards. Additional information is included in Manufacturer Declaration (Appendix

E).

•Before installation remove temporary items that protect fan during transport and storage (e.g. box, foil, inlet and outlet caps –do not

remove any guards) –Starting the fan with those items could lead to damage of the fan. Make sure that the fan is not damaged.

•Ensure that there are no foreign bodies (e.g. mounting elements, tools) inside fan and near of the unit, the fan is properly secured after

installation (the cover of connection box and inspection cover are closed and secured, the connecting elements are properly tightened).

Technical acceptance need to be carried out in accordance with Appendix C.

3.2 Assembly information

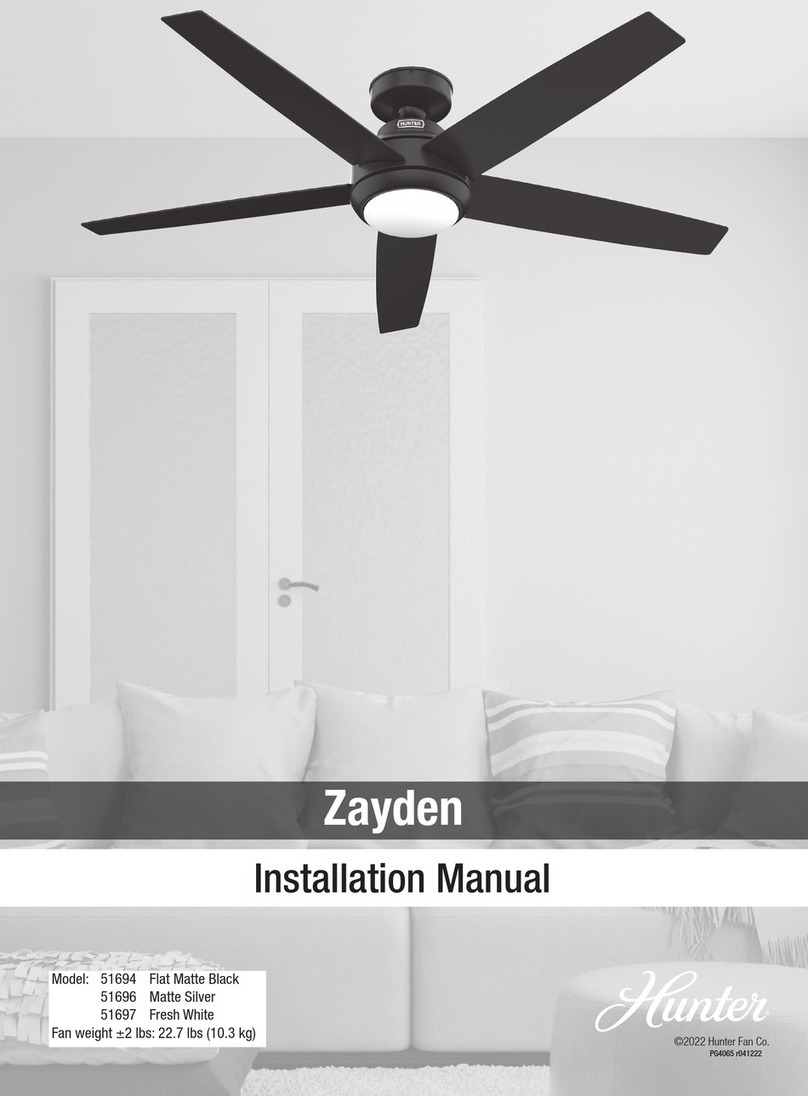

•Fan need to by mounted in possition presented on Fig 2., with horizontal motor shaft possition (with motor base on bottom). Other montage

possitions are allowed only after manufacturer approval. Fan need to be mounted with use of outlet flanges (all holes placed in flange need to

be used) or with use of dedicated feets (all holes in mountign feets need to be used). Fasteners secured against loosing need to be applied.

Fig. 2

Mounting position

A - mounting holes

B - mounting base

•Supporting construction has to be solid enough in order to carry the weight of the fan and generated vibration (including fan damage). The

fan cannot be exposed to vibration.

•It is recommended to apply measures minimizing transmission of vibration from/to the fan. For fans placed on vibro-isolators connecting on

inlet and outlet side need to be made in flexible form.

•Keep safe distance between installed device and inflammable elements (special attention to hot surfaces of device need to be paid).

•Keep free space from the fan outlet to allow free discharge of the pumped medium.

•Measures protecting user from burn by hot elements need to be applied.

3.3 Electrical connection guidelines

•The fan and power supply network must be protected in accordance with local law requirements.

•Detailed guidelines related to electrical connection are located in motor operation manual and on motor markings - those guidelines need to

be applied.

• The voltage and frequency of the fan power supply network must not exceed those given on the fan nameplate.

Single-phase motors are equipped with a bimetallic temperature sensor located in the stator winding. Sensor tip are placed in the motor

terminal box (additional cube). This sensor should be included in the power supply circuit fan protection (e.g. transmitter, contactor, etc.).

Despite the use of a bimetallic sensor, it is necessary to connect an overload fuse to protect the motor against excessive overload. Switch

setting must comply with the maximum allowable current indicated on the motor's nameplate. Three-phase motors are equipped with a PTC

resistance temperature sensor. The sensor terminals are placed in the motor connection box (additional cube). This sensor should be included

in the fan protection supply circuit (e.g. by using a PTC transmitter). Despite the use of a PTC sensor, it is necessary to connect a motor

protection (short-circuit-overload protection) to protect the motor against excessive overload. The switch setting must comply with the

maximum allowable current indicated on the motor's rating plate.

3.4 Impeller rotation direction

Make sure that after installation and during using the fan the impeller would rotate in correct direction. After mounting fan to proper

construction, with special care taken and in accordance with sector 1 and 4, launch the fan in impulse way (less than 1 second) and check, if

the impeller rotates in correct direction, generating airflow in proper direction. The work with impeller rotating in the wrong direction reduces

fan parameters and may damage it. In case of improper impeller rotation, turn of power supply, wait until impeller stops and change proper

power supplying wires in junction box.

A

A

A

A

B

Roof fans type ROOF-H

tel. +48 22 751 95 50 www.ventur.eu fax. +48 22 751 22 59 5/11

4. USE

4.1 Use guidelines

•Make sure that turning on of the fan does not make any hazard for personnel and property. Follow the guidelines featured in section 1.2.

•The fan is designed for continuous operations (S1) –too high frequency of starting a fan may lead to motor overheat and damage.

•In case of activation of any electrical protection, detection of damage, unit must by immediately turn out off use.

•The device is adapted to work in certain range of characteristic. Too low volume flow rate of medium, start/work of device with completely

closed inlet and/or outlet may lead to motor overheat caused by current consumption exceeding value on the rating plate (current consumed

by fan grows as resistance of installation grows).

•Units work parameters (temperature of medium, ambient temperature, min and max flow rate....) refer to rated speed of motor.

5. MAINTENANCE, REVIEW

5.1 Maintenance guidelines

•During maintenance and review follow the guidelines contained in point 1.2

•Fan need to be subject of regular review and maintenance (point 5.2).

•Maintenance and review of motor need to be overtaken in accordance with motor documentation and markings. Exchange

of motor bearings need to be made before the end of current bearing lifetime.

•To clean fan construction use slightly damp delicate material. It is prohibited to use detergents, liquids under pressure and tools that may

scratch the unit surface.

•The fan need to be turned on at least once a month (minimum couple of impeller turns).

•Ensure that there are no foreign bodies (e.g. assembly components, tools) near and inside the fan, the impeller is not blocked, the unit is

clean, dry and secured after maintenance and review. After cleaning finishes, turn on the fan at max speed for 30 minutes.

•Access to the electric motor and rotor can be accessed through engine cover disassembly.

•During review special attention to the following need to be paid:

dust and dirt

Prevent the accumulation of dust/dirt on and inside the fan. Dirt accumulated on: grids –may reduce the fan parameters;

housing and motor –can reduce the cooling; hot surfaces –may ignite. Special attention must be paid to motor cooling

impeller and its cover. Reduction of cooling ability may lead to overheat of motor without working of safety devices.

corrosion

Corrosion of the fan may lead to mechanical damage of it. It is forbidden to use the fan if corrosion appears

overload

Exceeding of nominal current may be caused by improper choice of fan, mechanical damage (e.g. impeller, bearing),

improper electrical connection. Current value must be controlled, and if its growth is noticed, the reason need to be

determined and device need to be repaired. Current value cannot exceed nominal value.

vibration

Excessive vibration may cause mechanical damage of the fan or it mounting construction. The vibration increase can

indicate bearings damge or loss of impeller balance. Vibration value need to be controlled, and if its growth is noticed, the

reason need to be determined and device must be repaired.

Maximum vibration value on bearings (perpendicular to motor shaft) after fan installation cannot exceed value presented

in table below:

rigidly mounted*

flexibly monted*

peak

r.m.s

peak

r.m.s.

6.4 mm/s

4.5 mm/s

8.8 mm/s

6.3 mm/s

*according to ISO 14694

Note: Vibration measurement on bearings need to be made with specialistic equipement that allows safe control -

without risk of contact of user with rotating elements (see ISO 13857).

5.2 Review and maintenance

•The set between routine checks and maintenance need to be determined by user, based on the observation of unit and specific conditions of

use, in order to include specific work conditions. The set cannot be longer than introduced below.

•In the case of irregularities the device must be turn off and subjected to review, maintenance and possible repairs / cleaning (when dirt

occurs). Examples of reasons for device to work in emergency mode are given in Appendix D.

•Staff operating the device must be familiar with it normal working conditions. If the fan work differ from it normal working conditions it need

to be turn off from work and inspected.

Recommended daily review:

•Device is undamaged, stable and works properly;

•There are not any leaks, smoke from motor;

•Device does not emit any untypical noise, vibration and does not heat up excessively;

•Device is clean (general control), corrosion does not occur (general control);

•Wires are not damaged;

•There are no untypical leaks from fan;

•Covers are in proper state and clean.

Mmonthly review

•Fan current value is not higher than beginning value;

•The vibration value has not increased in relation to the initial value;

•Device and covers are clean;

•Device is clean, filter is not clogged.

Roof fans type ROOF-H

6/11 tel. + 48 22 751 95 50 www.ventur.eu fax. +48 22 751 22 59

Review once per 3 months, not less than 6 month and 3000 hours of work

•Corrosion does not occur;

•Fasteners state is proper (they are properly tightened);

•Security devices are working and set properly, protection against electrical shock is effective;

•Motor insulation resistance value is correct;

•Vibration value is lower than permissible;

•Structure is complete, components are not damaged (e.g. by abrasion).

Minimum every 10 years it is necessary to control the impeller due to fatigue strength. After the fan operation in the smoke removal mode,

the device should be replaced with new ones.

6. REPAIR, WARRANTY

Use only original spare parts and original accessories. Fan repairs need to be made by Venture Industries Sp. z o.o. service or outside, after

manufacturer permission. Warrantee conditions are described in guarantee card.

7. DISMANTLING AND RECYCLING

Disconnect unit from its power supply, and dismount according to the guidelines from section 1 of this instruction. Therefore, please deposit

all left-over material and packaging in their corresponding recycling containers and hand in the replaced machines to the nearest handler of

this type of waste product.

Roof fans type ROOF-H

tel. +48 22 751 95 50 www.ventur.eu fax. +48 22 751 22 59 7/11

APPENDIX A - (SCHEMATIC DIAGRAM OF THE FAN / LIST OF DEVICES)

1. General overview

A –air inlet

B –airoutlet

C –fan base

D –inlet nozzle

E –outlet cover

F –impeller

G –motor support plate

H, J –motor cover

I –electric motor

2. Part list

1.

fan base

2.

inlet nozzle

3.

outlet cover and brackets

4.

impeller

5.

motor support plate

6.

electric motor

7.

motor cover

8.

motor cover

The fan elements (1, 2, 7 and 8) are made of aluminum sheet, elements (3 and 5) made of stainless steel. The rotor (4) is welded and made of

aluminum sheet. Bolts and rivets made of aluminum, steel, galvanized steel, and stainless steel were used. The fan was sealed using high

temperature sealants. Detailed information concerning the components used and their tightening torque (not applicable to components with

which the motor is equipped) are attached to these instructions or are available on request.

Roof fans type ROOF-H

8/11 tel. + 48 22 751 95 50 www.ventur.eu fax. +48 22 751 22 59

APPENDIX B - (PRODUCT INDICATION)

[1] –product full name

[2] –motor type

[3] –motor power

[4] –nominal current

[5] –motor IP class

[6] –nominal voltage

[7] –power supply frequency

[8] –nominal fan speed

[9] –motor insulation class

[10] –weight

[11] –max ambient temperature

[12] –max temperature of transproted medium

[13] –informetion of accordance with ErP Directive (if apply)

[14] –serial number

[15] –Art. no.

Additional information indicated on the device

- arrow informing about correct direction of impeller rotation

- indications related to safe use of device

Roof fans type ROOF-H

tel. +48 22 751 95 50 www.ventur.eu fax. +48 22 751 22 59 9/11

APPENDIX C - (RECEIPT FORM)

Before launch

Check

confirmation

Type and model of fan are in accordance with the order.

The fan is undamaged.

There is no foreign body inside fan and the fan is clean.

The fan is reliably and solidly fixed in workplace.

The fan is properly levelled.

Wires are properly tightened.

Ambient temperature and transported medium temperature are compatible with fan nameplate.

Proper electrical protection is applied.

Grounding of fan is applied.

Mains supply is compatible with fan power supply.

Power supply disconnecting switch (with 3mm visible gap) is applied.

Personnel using the fan read and understood the operation and montage manual.

Proper inlet and outlet covers (grids) have been applied.

After fan launch (continuous work period minimum 30 minutes)

Readings and set of vibration measurement device has been written (they are available in future).

Value of current for each of phase does not exceed nominal one.

The vibration value is not higher than permitted.

Roof fans type ROOF-H

10/11 tel. + 48 22 751 95 50 www.ventur.eu fax. +48 22 751 22 59

APPENDIX D - (EXAMPLES OF DEVICE FAULTY WORKING)

SYMPTOMS

POSSIBLE REASON

Excessive vibration or

noise

•Used or damaged impeller;

•Fan levelled in wrong way;

•Dirt accumulated on impeller caused loss of balance;

•Impeller loss of balance;

•Parts rubbing;

•Damage or wear of bearings;

•Damage of measurement system, that is responsible for signalization of excessive vibration.

•Deformed motor shaft;

•Loose of impeller fix screw, impeller is loose on motor shaft;

•Loss of balance of motor impeller or damage of motor (wear/damage of bearing).

Motor overload

• Rubbing between fan impeller and housing;

• Damage or wear of bearings;

• Damage of motor windings (overheat, insulation degradation, insulation breakdown etc.);

• Damage of switch or security system;

• Failure of one of supply phases;

• Exceeding of maximum motor speed;

• Too low flow.

Failed fan start-up

• Rubbing between fan impeller and housing or foreign body (e.g. tool left after installation);

• Failure of one of supply phases;

• Failure of start-up system, e.g. Y/D;

• Reset of security devices has not been made, wrong security device;

• Motor connected in wrong way or damaged;

•Too low supply voltage.

Protective devices

activation during fan

work and overheating

• Excessive start-up time;

• Motor overload;

•Motor launching done too often (thermal protection –if applied or overheating);

•Improper set of protection system e.g. in system with PTC or thermocontact sensors (if applied);

• Improper cross-section of power supply wires;

• Lack of sufficient motor cooling eg. dirt placed on motor cooling impeller (thermal protection –if applied or

overheating).

Too low flow

•Damage of device;

•Too low power supply frequency;

•Obstacles in ventilation installation.

Table of contents

Other Venture Industries Fan manuals

Venture Industries

Venture Industries MPB-R Series User manual

Venture Industries

Venture Industries RF/EC Series User manual

Venture Industries

Venture Industries RBH Specification sheet

Venture Industries

Venture Industries RF User manual

Venture Industries

Venture Industries BL User manual

Venture Industries

Venture Industries AFC-HT-2-250-025T User manual

Venture Industries

Venture Industries RF User manual

Venture Industries

Venture Industries WNF Series User manual

Venture Industries

Venture Industries IBF Series User manual

Venture Industries

Venture Industries HB User manual