2 tel. (22) 751 95 50 www.venture.pl fax. (22) 751 22 59

INTRODUCTION

This manual covers fan listed on front page. It is source of information necessary for safe and proper use. Read this manual carefully before any

use of the device, comply with it requirements and keep it in place with easy access for users and service. If case of any

doubts about use of the fan, please contact with manufacturer.

After receiving the device - check

• whether the device is in compliance with order,

• whether the data on the rating plate are the same as desired.

• whether fan was not damaged during transport (e.g. there are no dents/cracks)

• whether a motor documentation (containing manual) is attached

In case of any irregularities, contact with your dealer or Venture Industries Sp. z o.o. service.

1. GENERAL INFORMATION

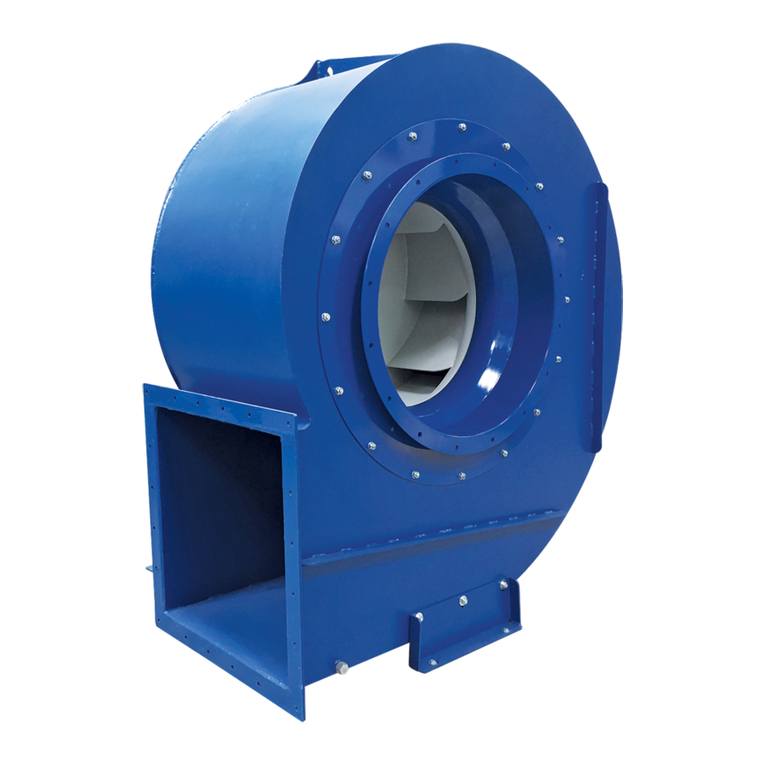

1.1Information about device

The fan is a not completed machine within the meaning of the Machinery Directive 2006/42/WE (please refer to the manufacturer's

declaration –Appendix E).

Fan is designed for use by trained, qualified adult persons in industrial environment. The fan is not designed for household or similar use.

The device is designed to transport clean air. Do not transport the explosive mixtures, solid elements, liquids, substances that cause

abrasion, chemically reactive compounds. Minimal temperature of transported medium need to be in conformity with motor operating

temperature but not lower than -15°C. Maximum temperature is determined on fan rating plate.

The fan must be protected from the weather (e.g. snow, rain, excessive sun radiation, lightning). The device is not designed to be installed

outdoor. The fan surrounding cannot contain explosive atmospheres, substances causing abrasion, chemically aggressive substances, viscous

substances, liquid, substances with high humidity. Minimal temperature of ambient medium need to be in conformity with motor operating

temperature but not lower than -15°C. Maximum temperature is determined on fan rating plate.

The device must not be exposed to radiation (such as microwave, UV, laser, x-ray).

The impeller has been balanced in accordance with minimum G6.3 class ISO 1940-1, and general construction of the fan in accordance with

cat. BV-3 ISO 14694

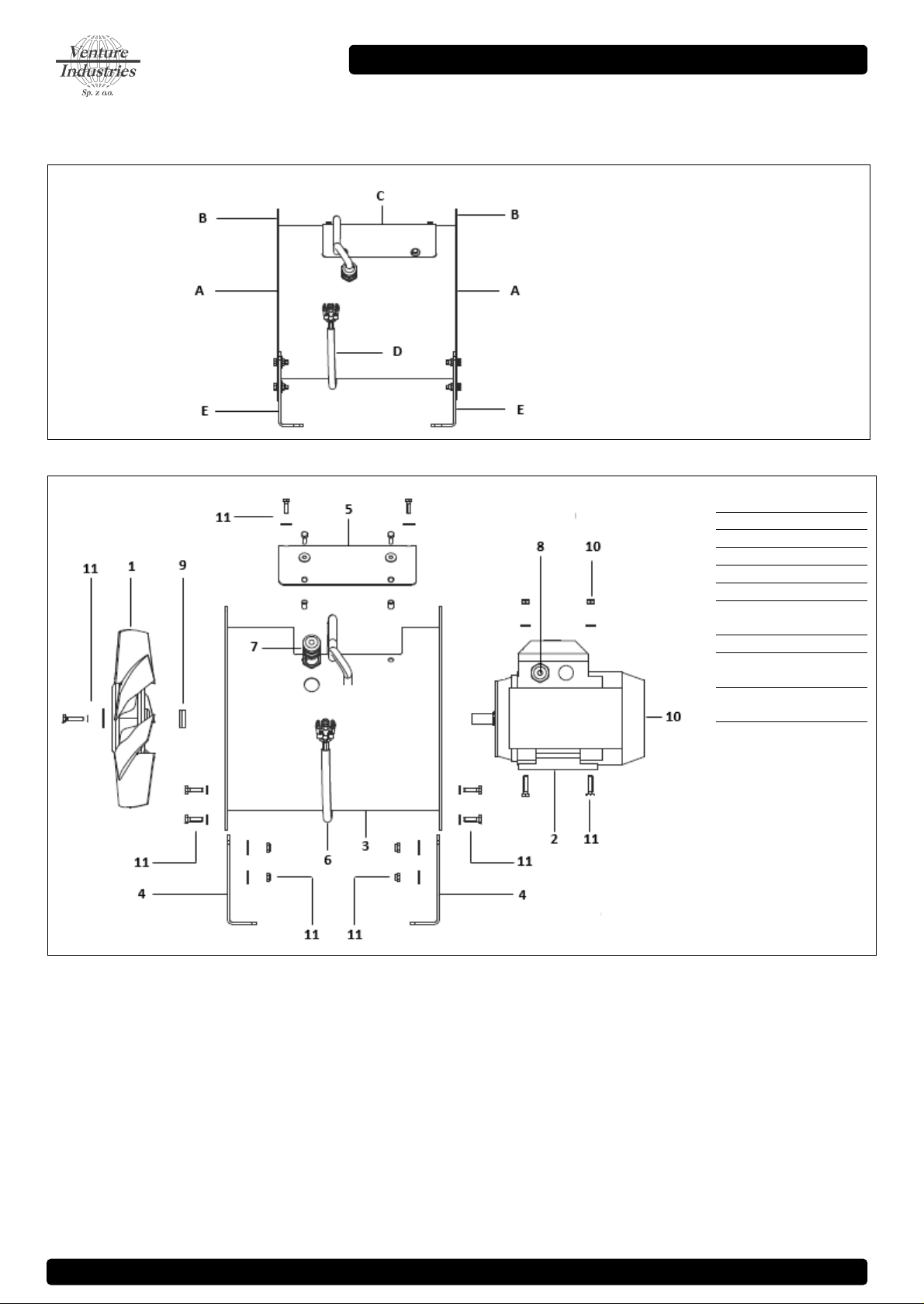

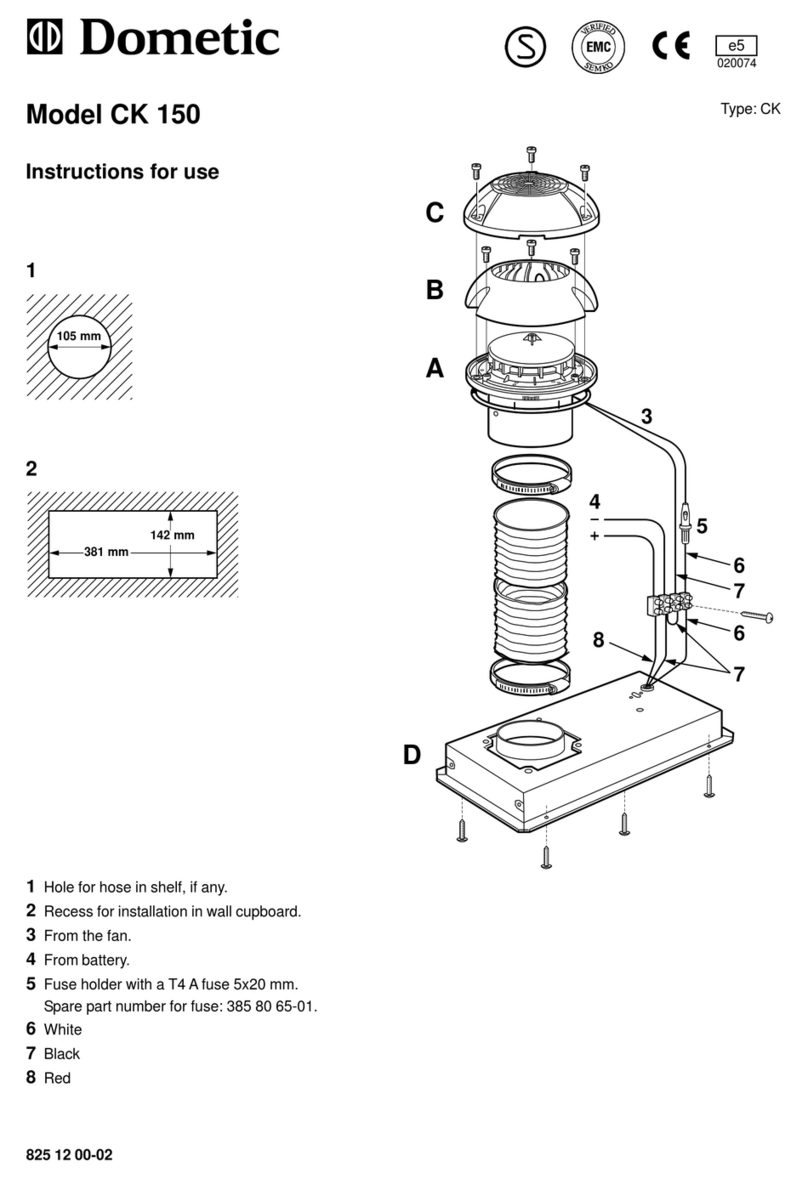

Description of construction of the fan has been included in Appendix A.

Additional information of the fan usage has been indicated on the device. Additional information have been included in Appendix B.

1.2 General risk and guidelines

During entire fan life cycle pay particular attention to the risk and guidelines presented below:

1.2.1 moveable components

The fan is equipped with moveable components (impeller of the device, impeller of the motor). Contact with them may cause

serious injury or death. The fan must not be used if covers (grids) and safety measures against contact with rotating parts have

not been installed.

1.2.2 suction

The fan has high suction power. Clothing, hair, foreign particles, and even body elements can be easily sucked in. It is forbidden to approach

the fan in “loose” clothing or reaching toward inlet of working fan. It need to be ensured, that no foreign body can be sucked in.

1.2.3 thrown elements

The air at the outlet of the fan has high energy. Elements sucked or placed inside the fan can be thrown with a high speed. The fan has stable,

solid construction, but as a result of damage or improper use some parts (elements with high kinetic energy) may be thrown away. Make sure

that before start and during operation of the fan there are no elements, that may be sucked in (pay special attention to fan inlet side) and

there are no person in stream of transported medium (on inlet and outlet side). Do not use fan without proper inlet and outlet covers (grids).

1.2.4 sharp edges

During manufacturing the fan sharp edges was grinded. However the fan may have edges touching which may cause injury.

We recommend the use of relevant protective gloves.

1.2.5. inertness

The fan has a high inertness. In case of no permanent fix turning on the fan will lead to it uncontrolled movement. The unit can be turn on

only after proper installation.

1.2.6 noise

The sound pressure level is dependent on the operation point. Check the sound pressure level and if necessary use silencers and/or individual

protection measures for personnel.

1.2.7 materials

In case of fire or transport of improper medium –fan parts can generate fumes hazardous to health.

1.2.8. environment

The fan can make over and under pressure. In areas where a specified air pressure and the quantity of air are required (e.g. in places with

combustion) make sure that there would be no deficit/excess of air.