Z

2028

79-

0D

PAGE 3 ©2012 Veris Industries USA 800.354.8556 or +1.503.598.4564 / suppor[email protected] 03122Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

TM

H8163-CB INSTALLATION GUIDE

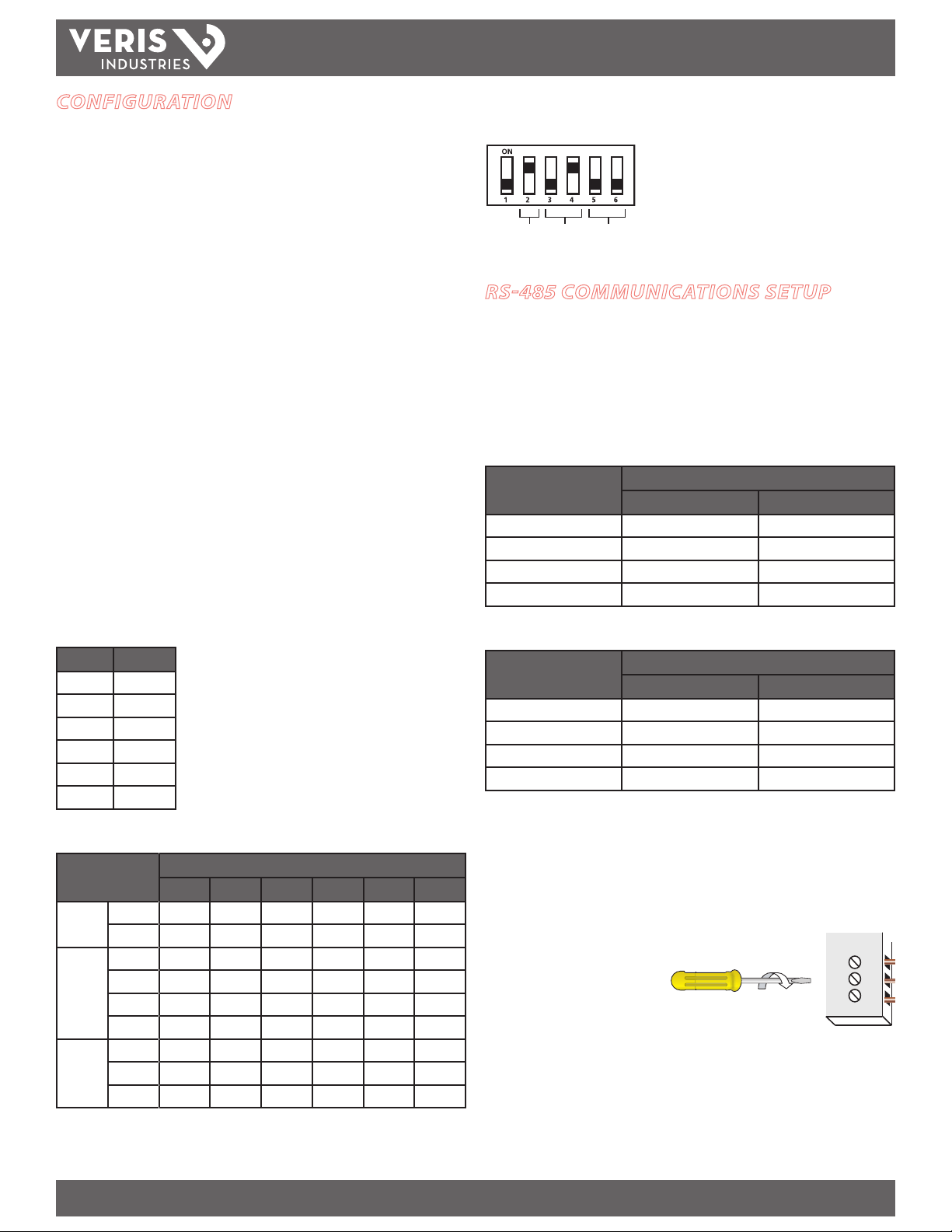

CONFIGURATION

This section describes the communications settings you must make to the H8163-CB.

When daisy-chaining Modbus devices, follow these guidelines:

• Connect up to 63 H8163-CB devices on a single daisy chain.

• Each H8163-CB device on the daisy chain must have a unique address.

Before connecting the H8163-CB to the RS-485 communication wires,

set the address according to directions on this page.

• Set the wiring type, baud rate, and parity according to directions in

“Selecting Wiring Type, Baud Rate, and Parity Settings” on this page. The

settings for each H8163-CB must match the other devices on its daisy

chain.

• For RS-485 cables, use shielded, twisted-pair wire (Belden Cable 1120A or

equivalent).

• Terminate the last device on the daisy chain to ensure reliable

communication per the RS-485 standard (120 Ω nominal impedence).

Selecting The Network Address DIP Switches

Use the network address DIP switches to select the network address. Each H8163-CB

on a daisy chain must have a unique network address (from 1 to 63). Devices with the

same address as another on the chain will be unable to communicate.

Always set the address before you install the H8163-CB in the energy meter and

before you connect the energy meter to the daisy chain.

Each of the six DIP switches has a unique address value. The Modbus Addressing

section on page 6 lists DIP switch positions for specic addresses.

Network Address DIP Switch Values

Switch Value

1 1

2 2

3 4

4 8

5 16

6 32

Selecting Wiring, Baud Rate, and Parity Settings

Parameter Switch Number and Setting

123456

Wire

Type

2-wire - On

4-wire - O

Baud

Rate

2400 - O O

4800 - On O

9600 - O On

19200 - On On

Parity

None - O O

Even -On O

Odd - On On

Setting the Communication DIP Switches

Switch 1 is unused. Always leave it in the OFF

position.

This example illustrates the default switch settings

for a 2-wire device that uses 9600 baud rate with

no parity.

RS-485 COMMUNICATIONS SETUP

Daisy Chain Maximum Distances

The maximum number of devices allowed on a single daisy chain is determined by

combining the baud rate, the length of the daisy chain, and the types of RS-485

devices (2-wire/4-wire) on the chain. The RS-485 interface will support daisy chains

that fall within the specications shown below.

4-Wire Daisy Chain Maximum Distances

Baud Rate Maximum Distances

1-16 Devices 17-32 Devices

2400 10,000 ft. (3048 m) 5000 ft. (1524 m)

4800 10,000 ft. (3048 m) 5000 ft. (1524 m)

9600 10,000 ft. (3048 m) 4000 ft. (1219 m)

19200 5000 ft. (1524 m) 2500 ft. (762 m)

2-Wire Daisy Chain Maximum Distances

Baud Rate Maximum Distances

1-8 Devices 9-16 Devices

2400 10,000 ft. (3048 m) 5000 ft. (1524 m)

4800 10,000 ft. (3048 m) 5000 ft. (1524 m)

9600 10,000 ft. (3048 m) 4000 ft. (1219 m)

19200 5000 ft. (1524 m) 2500 ft. (762 m)

Wiring the Connector

1. Remove the connector from the RS-485 communication terminals of the H8163-

CB.

2. Wire the communications connector as shown on page 4 (2-wire or 4-wire

communication). The wire type setting in the communication DIP switch must

match this wiring type.

3. Use a small, at-blade screwdriver

to tighten the connector screws.

Apply the correct torque: 0.37-0.44

ft·lb (0.5-0.6 N·m).

4. Replace the connector on the RS-485 communication terminals of the H8163-CB.

5. If the H8163-CB is the last device in a daisy chain, terminate it to ensure reliable

communication per the RS-485 standard (120 Ω nominal impedence).

0.37–0.44 ft•lb

(0.5–0.6 N•m)