TM

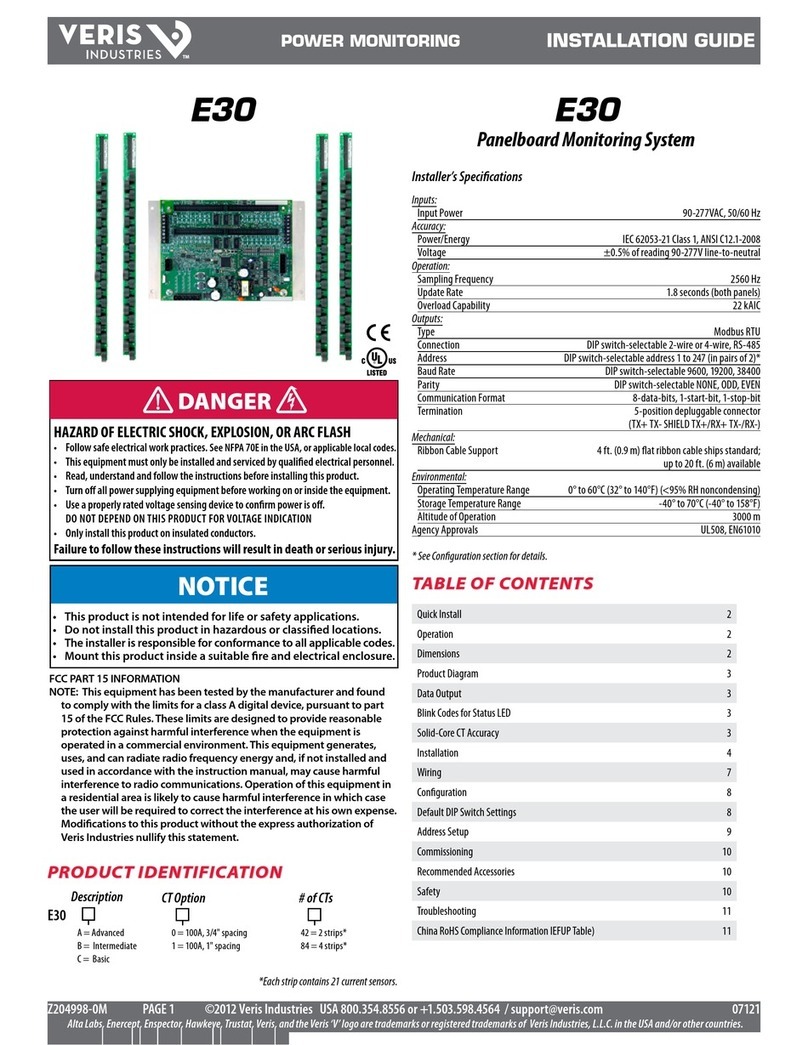

POWER MONITORING INSTALLATION GUIDE

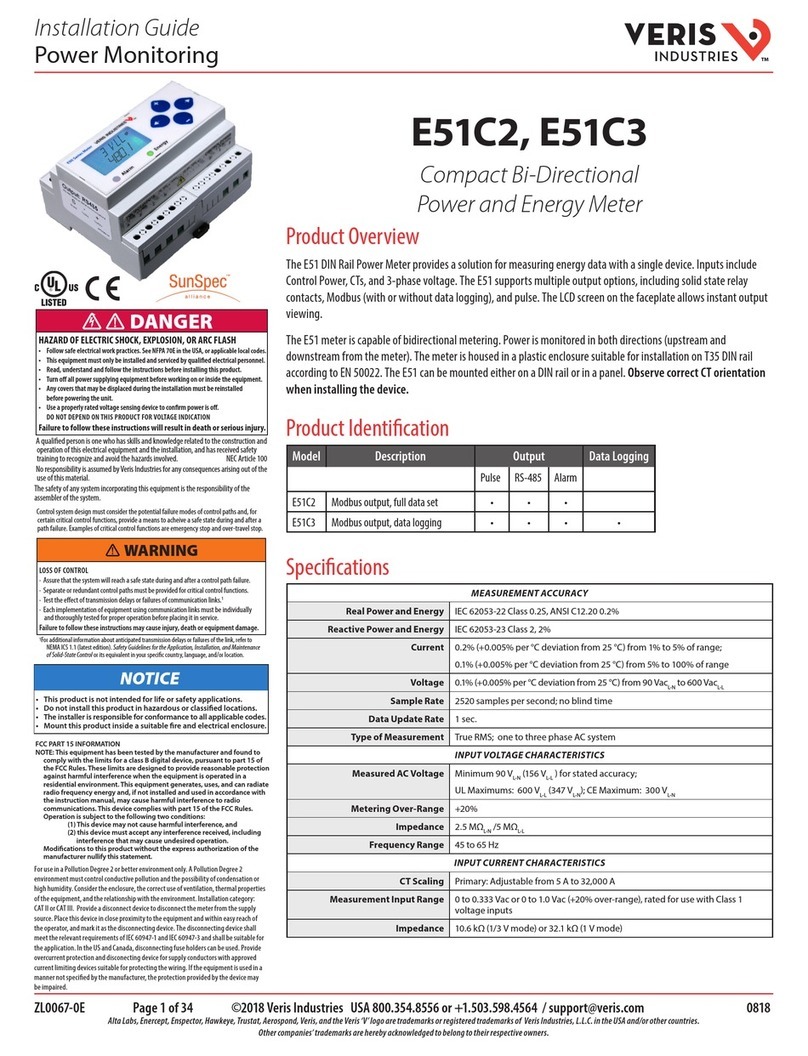

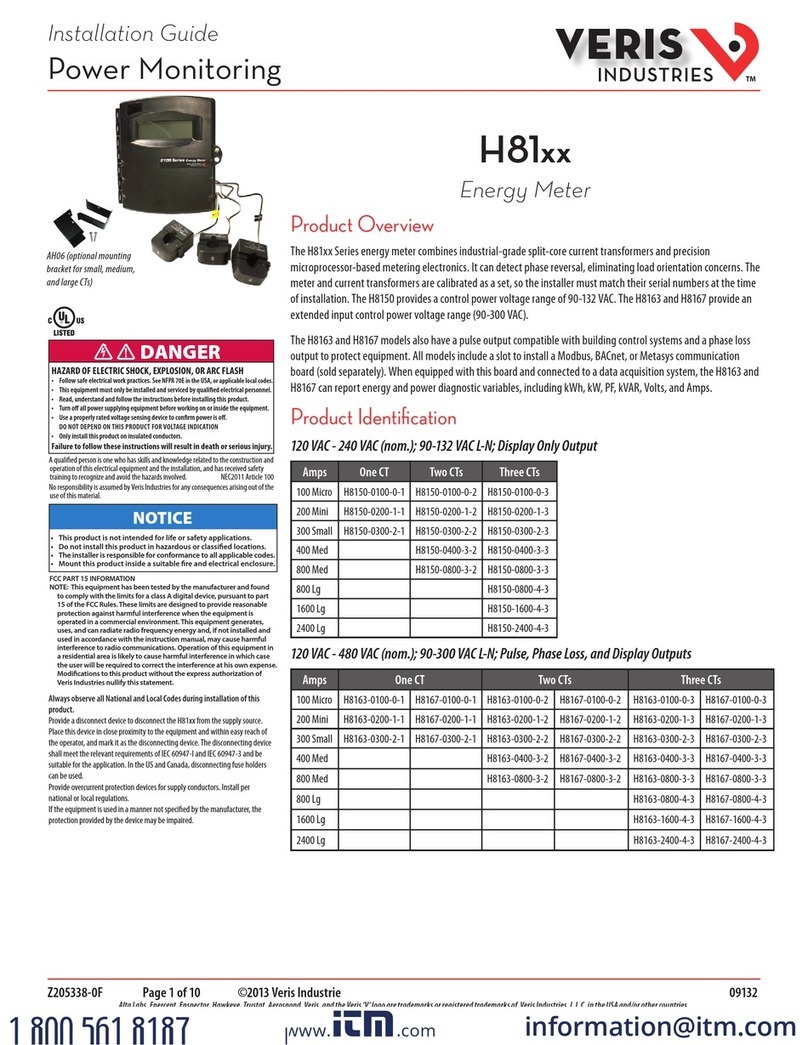

H81xx

SPECIFICATIONS

Inputs:

H8150 90 to 132VAC line-to-neutral

H8163, H8167 90 to 300VAC line-to-neutral

Frequency 50/60 Hz

Accuracy:

System Accuracy ±1% of reading from 2% to 100% of the CT current rating *

Sample Rate 1280 Hz

Outputs:

All Models

LCD 1.2” x 3.8” (31 mm x 97 mm) viewing area, 160 segments, backlit

H8163 and H8167:

Pulse Output N.O., Opto-Fet, 100mA@24VAC/DC

Pulse Rate 0.10, 0.25, 0.50, 1.00 kWh per pulse (jumper selectable)

Pulse Width 200msec closed

Phase Loss Alarm Output H8163: N.O. (opens on alarm, remains open while alarm persists);

H8167: N.C. (closes on alarm, remains closed while alarm persists);

Both H8163 and H8167: Opto-Fet, 100mA@24VAC/DC;

Fixed threshold 25% below any other phase

Mechanical:

Protection Class NEMA 1

Insulation Class 600 VAC **

Environmental:

Operating Temperature Range 0° to 50°C (32° to 122°F)

Storage Temperature Range -40°C to 70°C (-40° to 158°F)

Humidity Range 0-95% RH, non-condensing

Altitude of Operation 0 to 2000 m

Electrical Services:

H8150 120/240 VAC with neutral, 208Y/120 VAC line-to-neutral

H8163, H8167 Any Wye service in which the phase L-N voltage is ≤300VAC and

the phase-to-phase voltage is ≤480 VAC nom. with neutral

Agency Approvals UL 3111-1

Installation Category Cat III, pollution degree 2

* Meters and current transformers are calibrated as a set. To achieve this accuracy, match the

serial numbers on the transformers and the meter at the time of installation (does not apply to

100 A CTs).

** Do not apply 600V class current transformers to circuits having a phase-to-phase voltage

greater than 600V without adequate additional insulation between primary conductor and

current transformers.

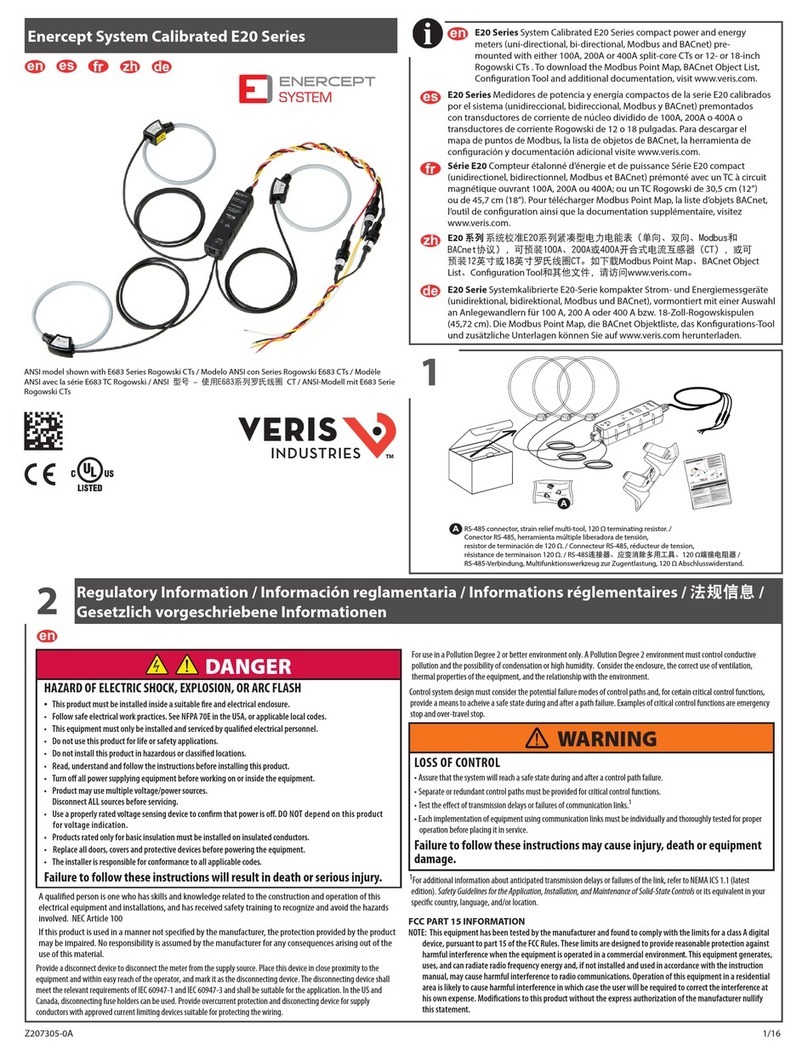

Energy Meter

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices. See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn off all power supplying equipment before working on or inside the equipment.

• Use a properly rated voltage sensing device to confirm power is off.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

• Only install this product on insulated conductors.

Failure to follow these instructions will result in death or serious injury.

A qualied person is one who has skills and knowledge related to the construction and

operation of this electrical equipment and the installation, and has received safety

training to recognize and avoid the hazards involved. NEC2009 Article 100

No responsibility is assumed byVeris Industries for any consequences arising out of the

use of this material.

DANGER

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classified locations.

• The installer is responsible for conformance to all applicable codes.

• Mount this product inside a suitable fire and electrical enclosure.

FCC PART 15 INFORMATION

NOTE: This equipment has been tested by the manufacturer and found

to comply with the limits for a class A digital device, pursuant to part

15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference when the equipment is

operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and

used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

Modifications to this product without the express authorization of

Veris Industries nullify this statement.

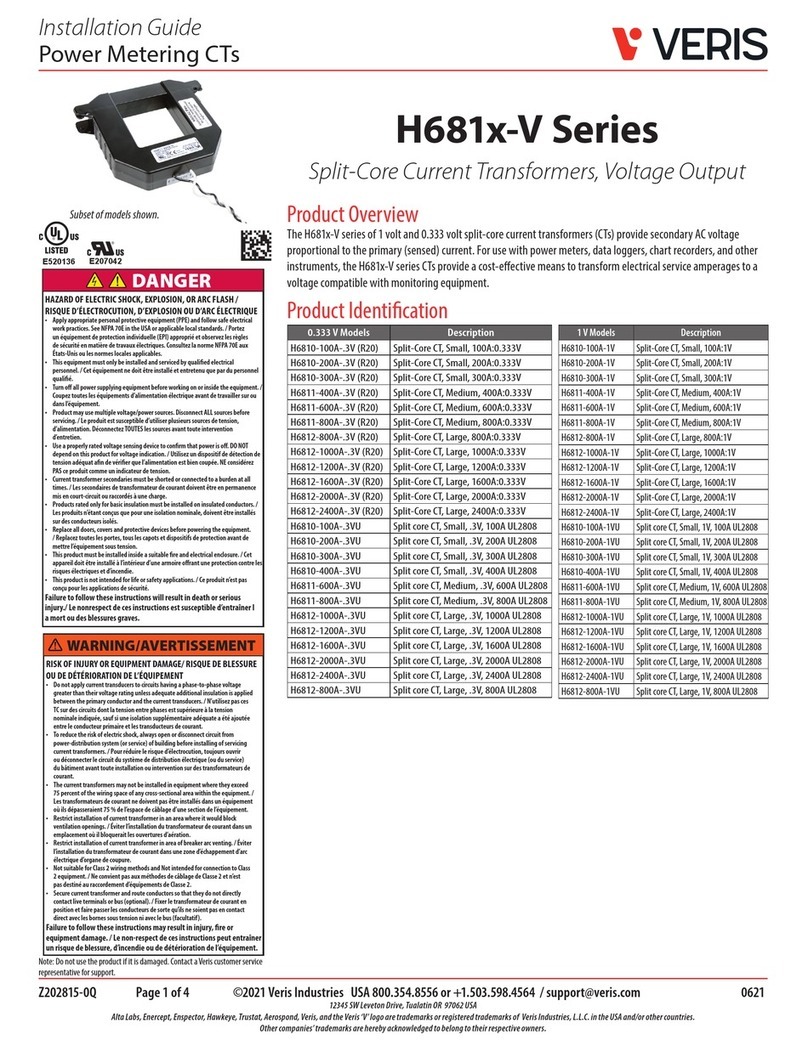

AH06 (optional mount-

ing bracket for small,

medium, and large CTs)

Always observe all National and Local Codes during installation

of this product.

Provide a disconnect device to disconnect the H81xx from the supply source. Place

this device in close proximity to the equipment and within easy reach of the operator,

and mark it as the disconnecting device. The disconnecting device shall meet

the relevant requirements of IEC 60947-I and IEC 60947-3 and be suitable for the

application. In the US and Canada, disconnecting fuse holders can be used.

Provide overcurrent protection devices for supply conductors. Install per national or

local regulations.

If the equipment is used in a manner not specied by the manufacturer, the

protection provided by the device may be impaired.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com