Z

L

0

0

6

7-

0

E

Page 1 of 34 ©2018 Veris Industries USA 800.354.8556 or +1.503.598.4564 / suppor[email protected] 0818 Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C. in the USA and/or other countries.

Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

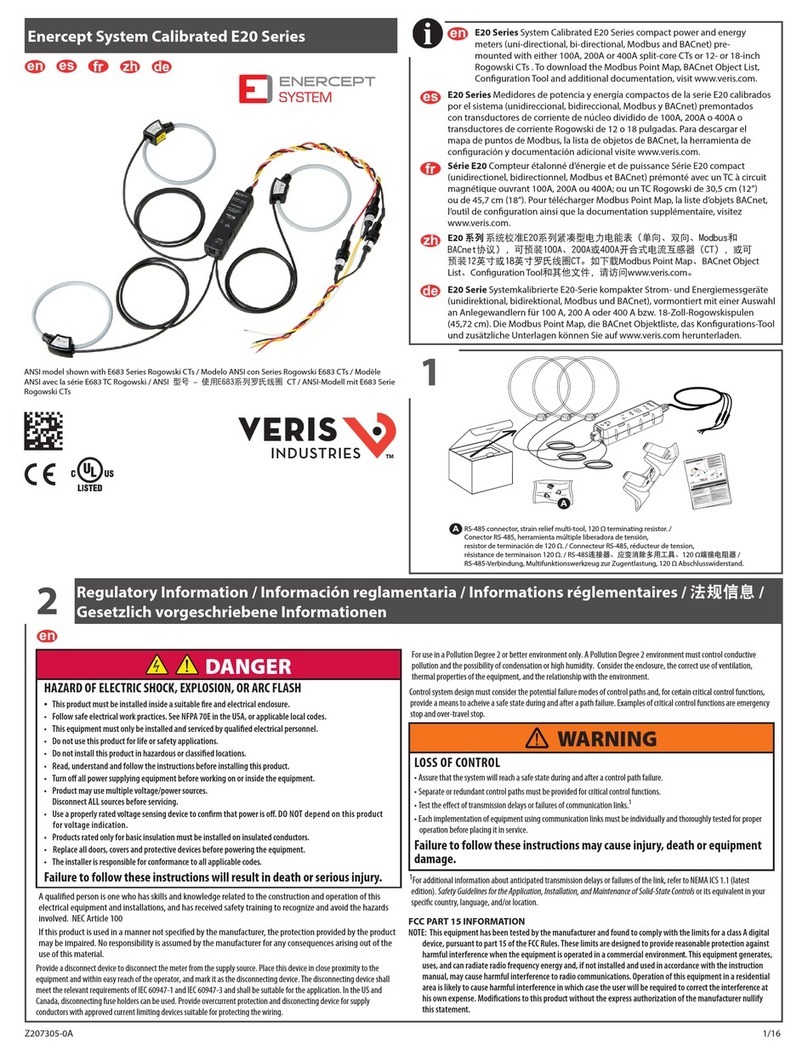

For use in a Pollution Degree 2 or better environment only. A Pollution Degree 2

environment must control conductive pollution and the possibility of condensation or

high humidity. Consider the enclosure, the correct use of ventilation, thermal properties

of the equipment, and the relationship with the environment. Installation category:

CAT II or CAT III. Provide a disconnect device to disconnect the meter from the supply

source. Place this device in close proximity to the equipment and within easy reach of

the operator, and mark it as the disconnecting device. The disconnecting device shall

meet the relevant requirements of IEC 60947-1 and IEC 60947-3 and shall be suitable for

the application. In the US and Canada, disconnecting fuse holders can be used. Provide

overcurrent protection and disconecting device for supply conductors with approved

current limiting devices suitable for protecting the wiring. If the equipment is used in a

manner not specied by the manufacturer, the protection provided by the device may

be impaired.

HAZARD OF ELECTRIC SHOCK, EXPLOSION, OR ARC FLASH

• Follow safe electrical work practices. See NFPA 70E in the USA, or applicable local codes.

• This equipment must only be installed and serviced by qualified electrical personnel.

• Read, understand and follow the instructions before installing this product.

• Turn off all power supplying equipment before working on or inside the equipment.

• Any covers that may be displaced during the installation must be reinstalled

before powering the unit.

• Use a properly rated voltage sensing device to confirm power is off.

DO NOT DEPEND ON THIS PRODUCT FOR VOLTAGE INDICATION

Failure to follow these instructions will result in death or serious injury.

A qualied person is one who has skills and knowledge related to the construction and

operation of this electrical equipment and the installation, and has received safety

training to recognize and avoid the hazards involved. NEC Article 100

No responsibility is assumed byVeris Industries for any consequences arising out of the

use of this material.

DANGER

NOTICE

• This product is not intended for life or safety applications.

• Do not install this product in hazardous or classied locations.

• The installer is responsible for conformance to all applicable codes.

• Mount this product inside a suitable re and electrical enclosure.

FCC PART 15 INFORMATION

NOTE: This equipment has been tested by the manufacturer and found to

comply with the limits for a class B digital device, pursuant to part 15 of

the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a

residential environment. This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in accordance with

the instruction manual, may cause harmful interference to radio

communications. This device complies with part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including

interference that may cause undesired operation.

Modifications to this product without the express authorization of the

manufacturer nullify this statement.

WARNING

LOSS OF CONTROL

∙ Assure that the system will reach a safe state during and after a control path failure.

∙ Separate or redundant control paths must be provided for critical control functions.

∙ Test the eect of transmission delays or failures of communication links.1

∙ Each implementation of equipment using communication links must be individually

and thoroughly tested for proper operation before placing it in service.

Failure to follow these instructions may cause injury, death or equipment damage.

1For additional information about anticipated transmission delays or failures of the link, refer to

NEMA ICS 1.1 (latest edition). Safety Guidelines for the Application, Installation, and Maintenance

of Solid-State Control or its equivalent in your specic country, language, and/or location.

Control system design must consider the potential failure modes of control paths and, for

certain critical control functions, provide a means to acheive a safe state during and after a

path failure. Examples of critical control functions are emergency stop and over-travel stop.

TM

Installation Guide

Power Monitoring

The safety of any system incorporating this equipment is the responsibility of the

assembler of the system.

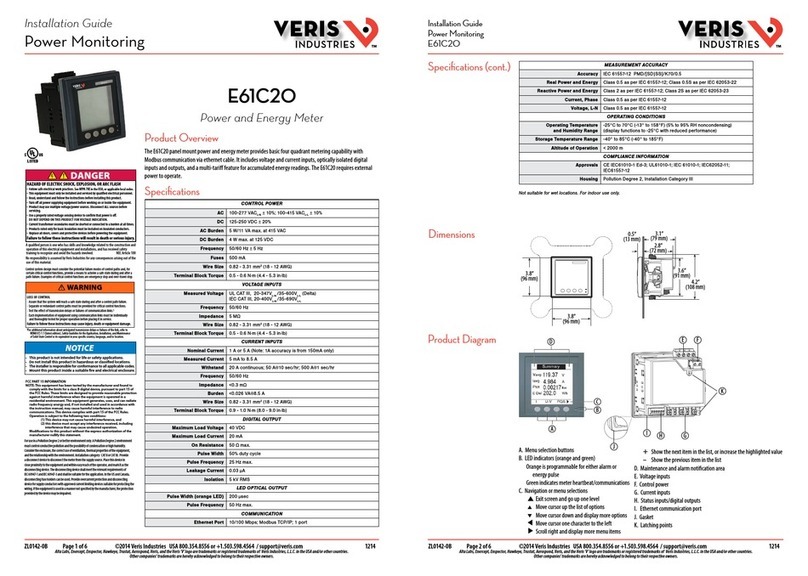

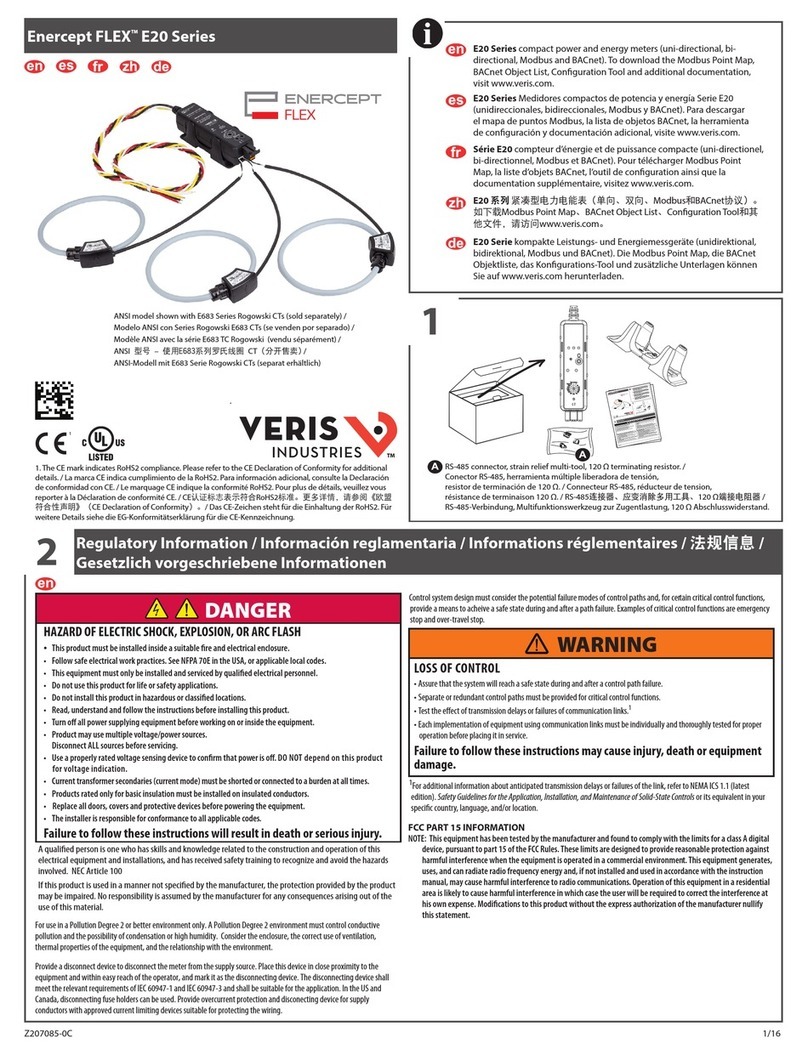

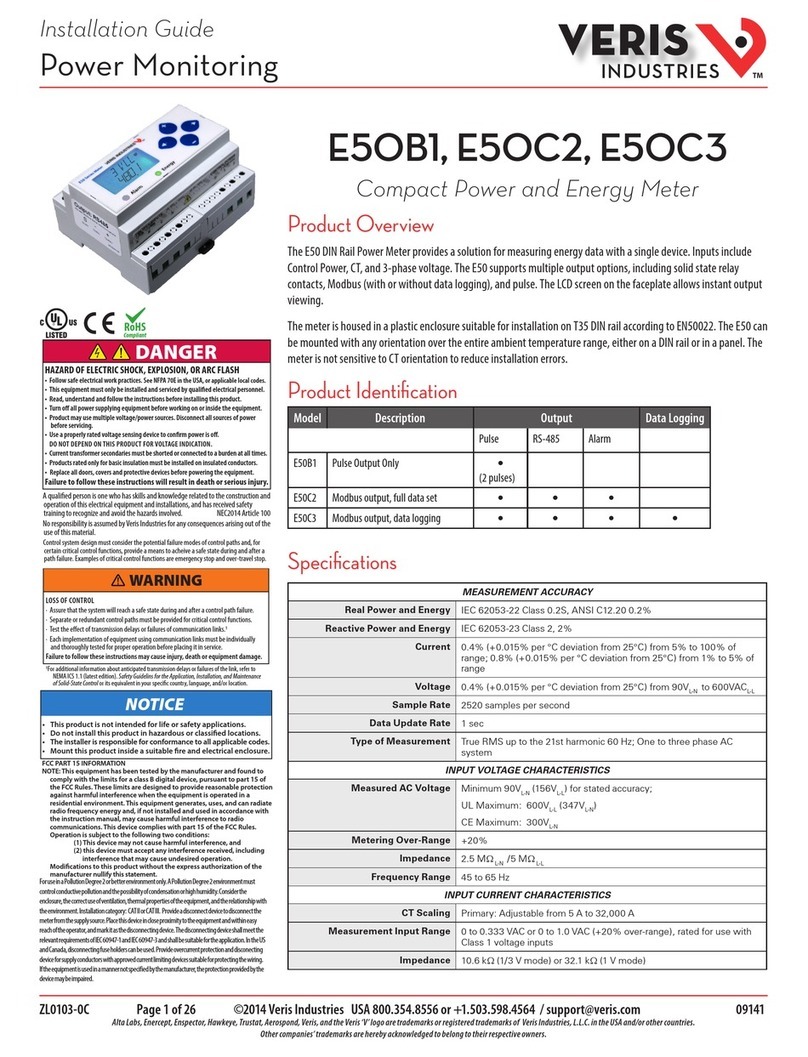

Product Overview

The E51 DIN Rail Power Meter provides a solution for measuring energy data with a single device. Inputs include

Control Power, CTs, and 3-phase voltage. The E51 supports multiple output options, including solid state relay

contacts, Modbus (with or without data logging), and pulse. The LCD screen on the faceplate allows instant output

viewing.

The E51 meter is capable of bidirectional metering. Power is monitored in both directions (upstream and

downstream from the meter). The meter is housed in a plastic enclosure suitable for installation on T35 DIN rail

according to EN 50022. The E51 can be mounted either on a DIN rail or in a panel. Observe correct CT orientation

when installing the device.

E51C2, E51C3

Compact Bi-Directional

Power and Energy Meter

Specications

MEASUREMENT ACCURACY

Real Power and Energy IEC 62053-22 Class 0.2S, ANSI C12.20 0.2%

Reactive Power and Energy IEC 62053-23 Class 2, 2%

Current 0.2% (+0.005% per °C deviation from 25 °C) from 1% to 5% of range;

0.1% (+0.005% per °C deviation from 25 °C) from 5% to 100% of range

Voltage 0.1% (+0.005% per °C deviation from 25 °C) from 90 VacL- N to 600 VacL- L

Sample Rate 2520 samples per second; no blind time

Data Update Rate 1 sec.

Type of Measurement True RMS; one to three phase AC system

INPUT VOLTAGE CHARACTERISTICS

Measured AC Voltage Minimum 90 VL-N (156 VL-L ) for stated accuracy;

UL Maximums: 600 VL-L (347 VL- N); CE Maximum: 300 VL-N

Metering Over-Range +20%

Impedance 2.5 MΩL- N /5 MΩL-L

Frequency Range 45 to 65 Hz

INPUT CURRENT CHARACTERISTICS

CT Scaling Primary: Adjustable from 5 A to 32,000 A

Measurement Input Range 0 to 0.333 Vac or 0 to 1.0 Vac (+20% over-range), rated for use with Class 1

voltage inputs

Impedance 10.6 kΩ (1/3 V mode) or 32.1 kΩ (1 V mode)

Product Identication

Model Description Output Data Logging

Pulse RS-485 Alarm

E51C2 Modbus output, full data set • • •

E51C3 Modbus output, data logging • • • •