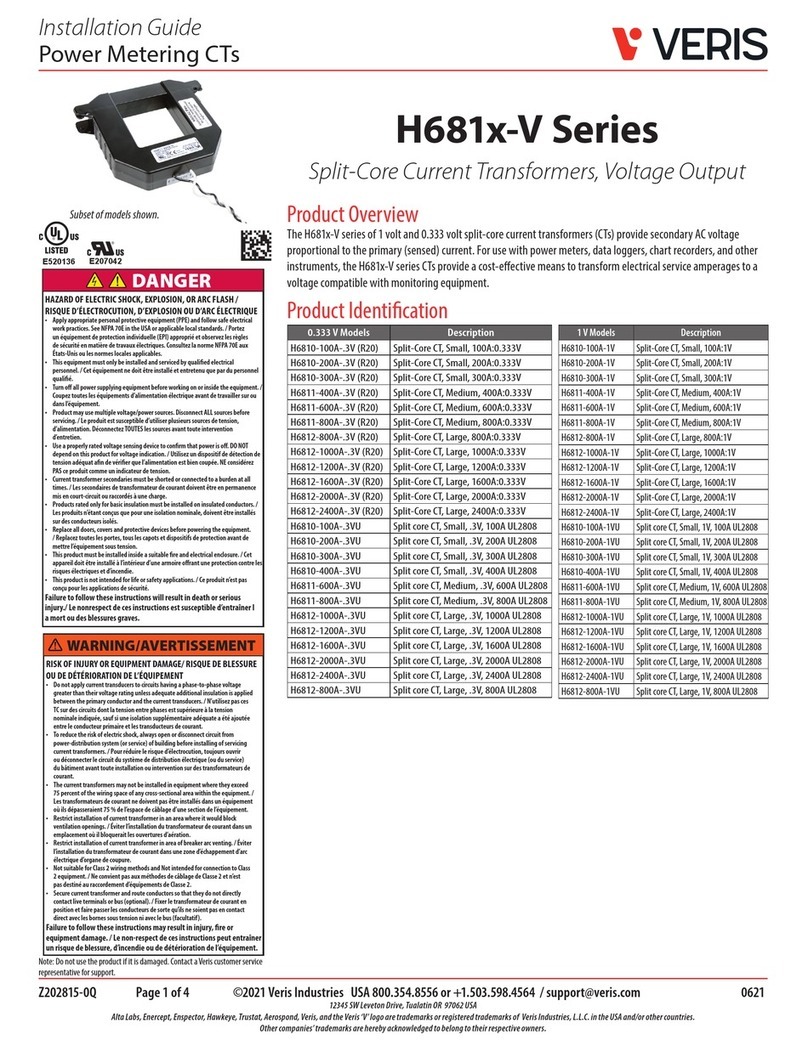

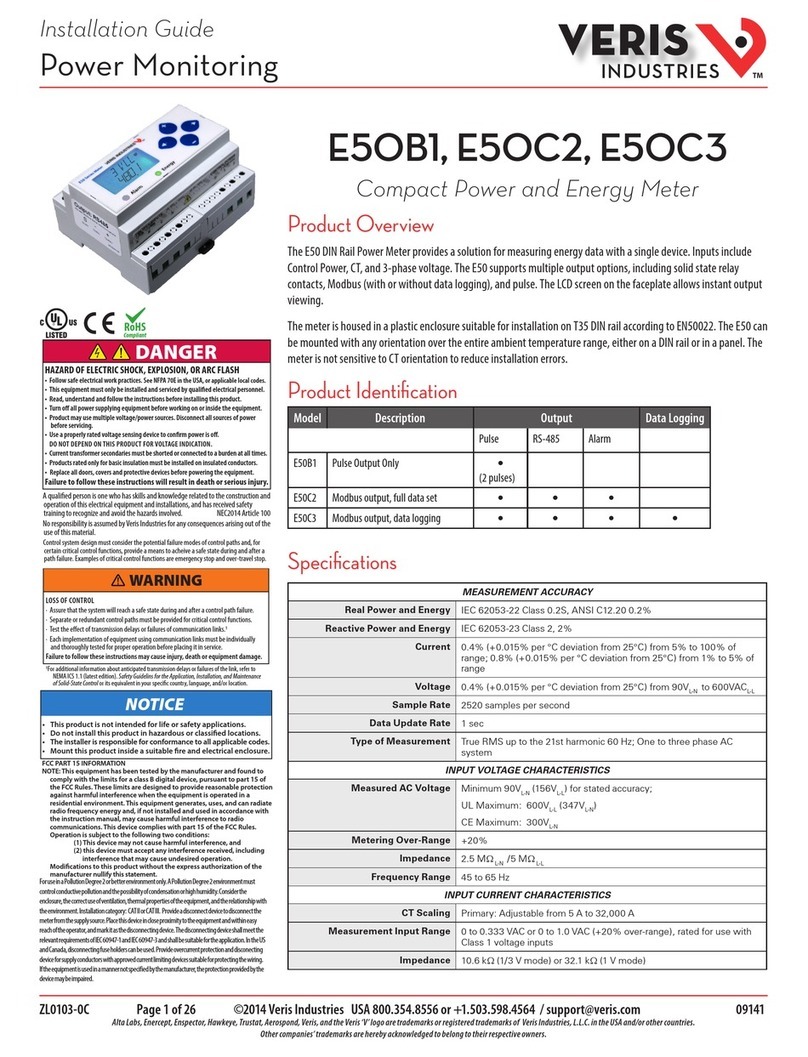

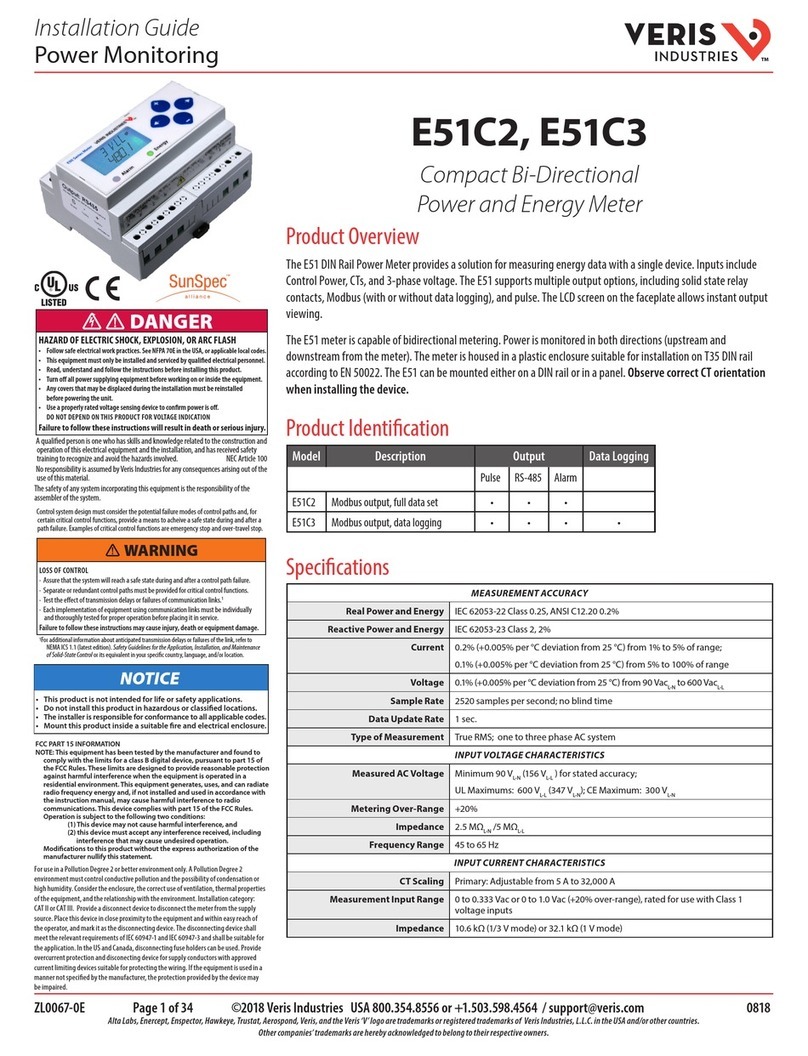

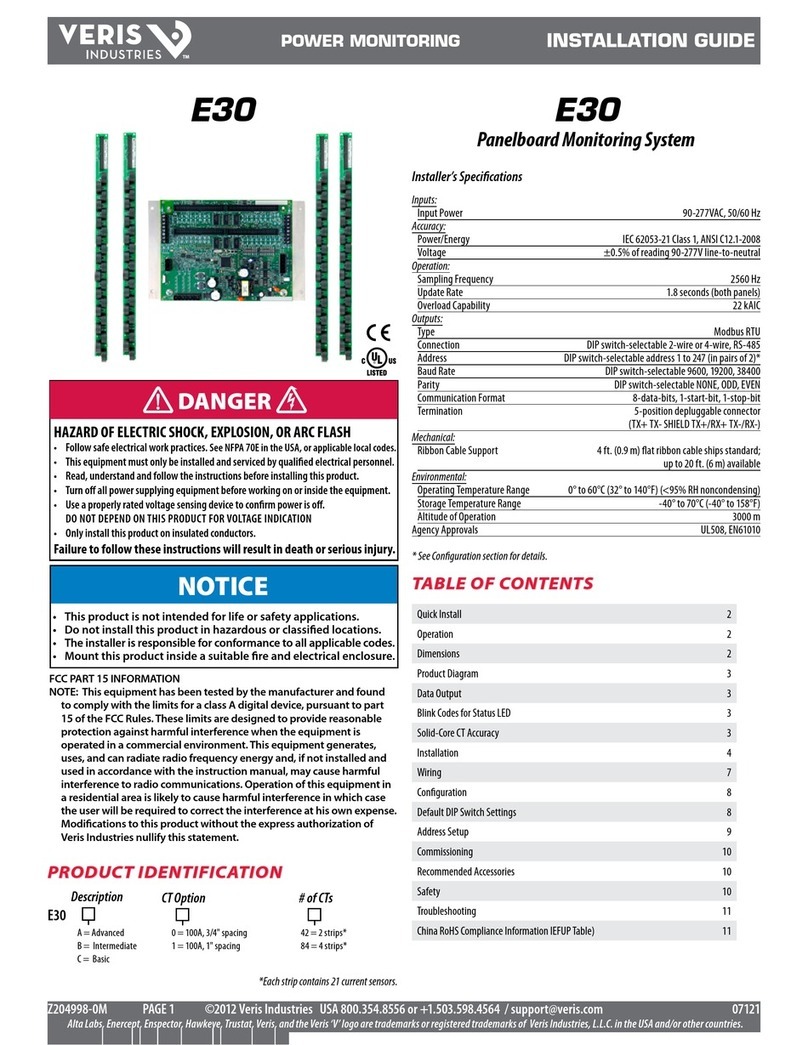

Product Identication

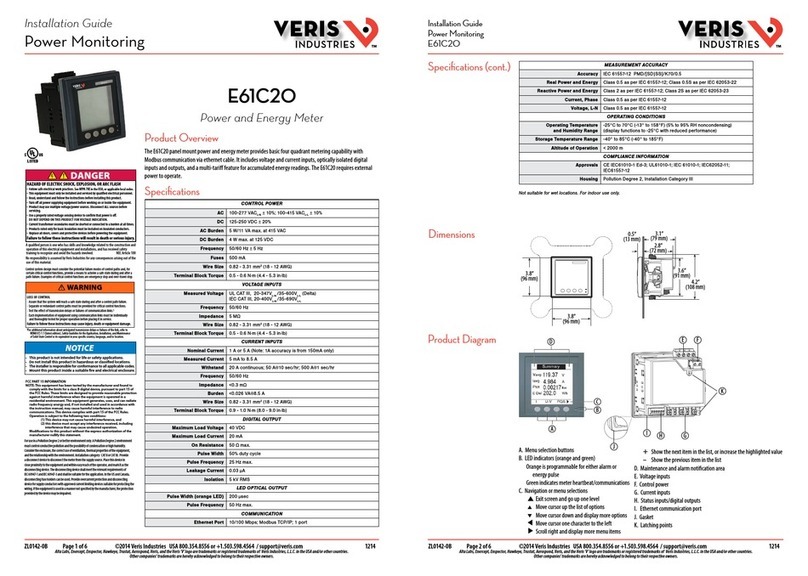

Dimensions

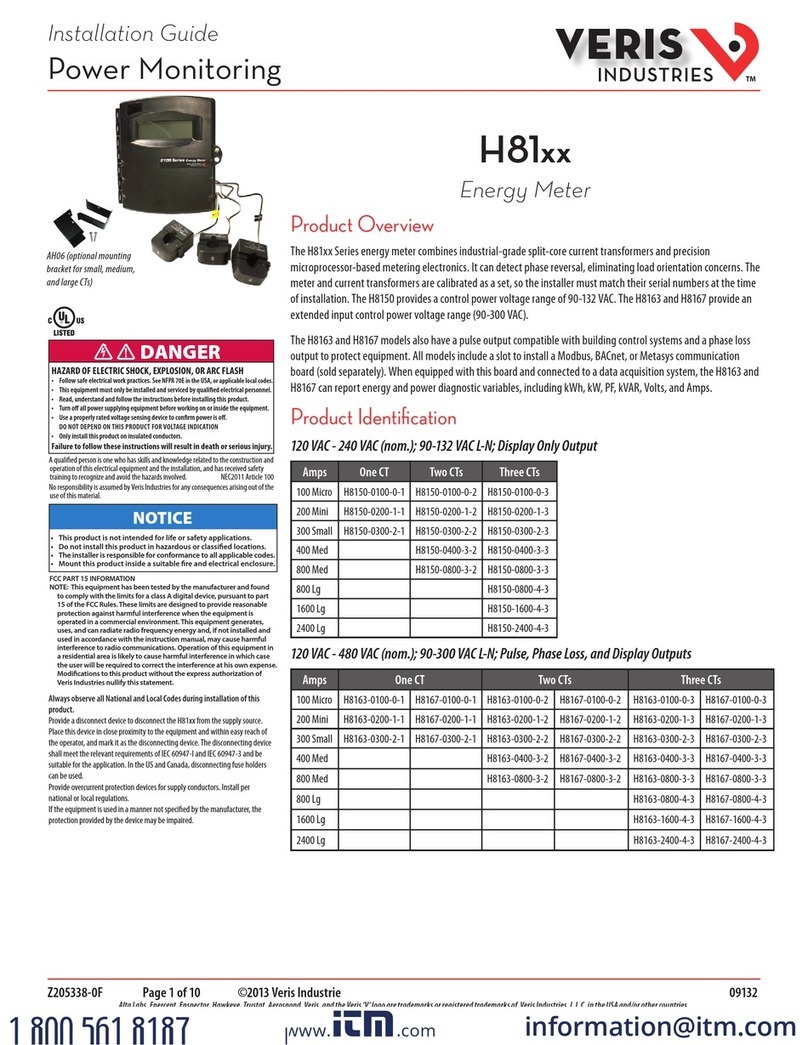

Product Overview

The PX3 transducer can measure either air pressure or velocity with the ip of a switch.

The PX3 is available in three installation congurations: duct, panel or universal. Duct and

panel models have two pressure and velocity options: 0-1 in. WC / 0-3,000 ft/min or

1-10 in. WC / 3,000-6,000 ft/min with four eld-selectable sub-ranges. The universal

model comes in one pressure/velocity range: 0-10 in. WC / 0-7,000 ft/min with seven

eld-selectable sub-ranges for pressure and eight for velocity. All variants are available

with and without display. The PX3 has an IP65/NEMA 4 environmental rating and a 5-year

limited warranty.

PX3 Series

Differential Pressure / Air Velocity Transducer

in. (mm)

PX3

Patent Pending

Media Compatibility Dry air or inert gas

Input Power Three-wire Volt mode: 24 Vac or 12-30 Vdc*

Two-wire mA mode: 12-30 Vdc*

Output Power Field-selectable: 2-wire, loop-powered 4-20 mA

Minimum input voltage for 4 to 20 mA operation: 250 Ω loop = 12 Vdc; 500 Ω loop = 19 Vdc

(DC only, clipped and capped), 24 Vac/dc or 3-wire 0-5V/0-10V

Minimum load resistance for Volt operation: 5 kΩ

01 Pressure

Range

Pressure

Mode

Unidirectional: 0.1/0.25/0.5/1 in. WC FS, switch selectable

Bidirectional: ±0.1/±0.25/±0.5/±1 in. WC FS, switch selectable

Unidirectional: 25/50/100/250 Pa FS, switch selectable

Bidirectional: ±25/±50/±100/±250 Pa FS, switch selectable

Velocity

Mode

500/1,000/2,000/3,000 ft/min

2.5/5/10/15 m/s

02 Pressure

Range

Pressure

Mode

Unidirectional: 1.0/2.5/5/10 in. WC FS, switch selectable

Bidirectional: ±1.0/±2.5/±5/±10 in. WC FS, switch selectable

Unidirectional: 250/500/1,000/2,500 Pa FS, switch selectable

Bidirectional: ±250/±500/±1,000/±2,500 Pa FS, switch selectable

Velocity

Mode

3,000/4,000/5,000/6,000 ft/min

15/20/25/30 m/s

05 Pressure

Range

Pressure

Mode

Unidirectional: 0.1/0.25/0.5/1/2.5/5/10 in. WC FS, switch selectable

Bidirectional: ±0.1/±0.25/±0.5/±1/±2.5/±5/±10 in. WC FS, switch selectable

Unidirectional: 25/50/100/250/500/1,000/2,500 Pa FS, switch selectable

Bidirectional: ±25/±50/±100/±250/±500k /±1,000/±2,500 Pa FS, switch selectable

Velocity

Mode

500/1,000/2,000/3,000/4,000/5,000/6,000/7,000 ft/min

2.5/5/10/15/20/25/30/35 m/s

Response Time Standard: T95 in 20 sec, Fast: T95 in 2 sec, DIP switch selectable

Mode Unidirectional or bidirectional, DIP switch selectable

Display (Option) Pressure mode: Signed 3-1/2 digit LCD, indicates pressure, overrange indicator

Velocity mode: Signed 4-1/2 digit LCD, indicates velocity, overrange indicator

Proof Pressure 3 psid (20, 600 Pa)

Burst Pressure 5 psid (34, 500 Pa)

Pressure Mode Accuracy ±1% FS (combined linearity and hysteresis)

Velocity Mode Accuracy ±90 ft/min (±0.45 m/s) plus 5% of measured value**

Temperature Eect 1” (250 Pa) models: 0.05%/°C; 10” (2,500 Pa) models: 0.01%/°C

(Relative to 25 °C) 0 to 50 °C (32 to 122 °F)

Zero Drift (1-year) 1” (250 Pa) models: 2.0% max.; 10” (2,500 Pa) models: 0.5% max.

Zero Adjust Pushbutton auto-zero and digital input (2-position terminal block)

Operating Environment 0 to 60 °C (32 to 140 °F)

Altitude of Operation 0 to 3,000 m

Pollution Degree 2

Humidity Range 100% RH, non-condensing

Mounting Location For indoor use only.

Fittings Brass barb; 0.24” (6.1 mm) o.d.

Suggested Cable Shielded:

Belden #9939 (22 AWG) 3-wire multi-conductor (or similar)

Belden #9940 (22 AWG) 4-wire multi-conductor (or similar)

Belden #9939 (22 AWG) 5-wire multi-conductor (or similar)

Unshielded:

Belden #8443 (22 AWG) 3-wire multi-conductor (or similar)

Belden #8444 (22 AWG) 4-wire multi-conductor (or similar)

Belden #8445 (22 AWG) 5-wire multi-conductor (or similar)

Environmental Rating IP65, NEMA 4

Specications

Installation, Wiring

& Conguration

FILTER

LOW HIGH

AIR FLOW

AIR FLOW

AIR FLOW

AIR FLOW

Static Pressure

Panel Installations

Duct Installations

Dierential Pressure

1. Plan the installation. Panel or duct mount?

For velocity applications, use the VFXP Series air velocity/measurement probe or AA18,

AA19 or AA20 velocity pitot tubes. For use with the PX3P (panel) and PX3U (universal)

models in Velocity mode only. Sold separately.

2. For duct mount applications, thread the probe into the back of the device housing, as

shown in the dimensional drawing.

3. Congure the internal tubing for the selected installation method as described below.

Duct mount tubing conguration:

a. Connect the right-side tube to the rear brass barb marked as “-” on the

underside of the device housing.

b. Connect the left-side tube to the probe in the back of the device housing.

Panel mount tubing conguration:

a. Connect the right-side tube to the rear brass barb marked as “-” on the

underside of the device housing.

b. Connect the left-side tube to the front brass barb marked as “+” on the

underside of the device housing.

Installation, Wiring

& Conguration (cont.)

Specications (cont.)

4. Mount the transducer (see the screw hole diagram below).

5. For applications using conduit, remove the cable gland nut on the bottom of the unit.

Thread a standard 1/2-inch NPT female threaded coupler onto the body of the cable

gland. Connect the opposite end of the coupler to the conduit.

NOTICE

•

This product is not intended for life or

safety applications.

• Do not install this product in hazardous

or classied locations.

•

Read and understand the instructions

before installing this product.

• Turn o all power supplying equipment

before working on it.

•

The installer is responsible for

conformance to all applicable codes.

If this product is used in a manner not specied

by the manufacturer, the protection provided

by the product may be impaired. No

responsibility is assumed by the manufacturer

for any consequences arising out of the use of

this material.

AIR FLOW

Z207504-0D Page 3 of 8 ©2018 Veris Industries 12345 SW Leveton Drive, Tualatin, OR 97062 USA / 800.354.8556 or +1.503.598.4564 / support@veris.com 0518

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘ V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C.

in the USA and/or other countries. Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Z207504-0D Page 1 of 8 ©2018 Veris Industries 12345 SW Leveton Drive, Tualatin, OR 97062 USA / 800.354.8556 or +1.503.598.4564 / support@veris.com 0518

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘ V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C.

in the USA and/or other countries. Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Z207504-0D Page 4 of 8 ©2018 Veris Industries 12345 SW Leveton Drive, Tualatin, OR 97062 USA / 800.354.8556 or +1.503.598.4564 / support@veris.com 0518

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘ V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C.

in the USA and/or other countries. Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Z207504-0D Page 2 of 8 ©2018 Veris Industries 12345 SW Leveton Drive, Tualatin, OR 97062 USA / 800.354.8556 or +1.503.598.4564 / support@veris.com 0518

Alta Labs, Enercept, Enspector, Hawkeye, Trustat, Aerospond, Veris, and the Veris ‘ V’ logo are trademarks or registered trademarks of Veris Industries, L.L.C.

in the USA and/or other countries. Other companies’ trademarks are hereby acknowledged to belong to their respective owners.

Velocity with VFXP Probe Velocity with AA18/AA19/AA20 Pitot Tube

AIR FLOW

1.6

(42)

1.6

(42)

3.5

(88)

3.5

(88)

4.4

(112)

7.4

(188)

0.