2QuickReferenceGuideHotMeltDispensing VTK‐VS‐BA‐024e‐A

1QUICKREFERENCEGUIDEHOTMELTDISPENSING

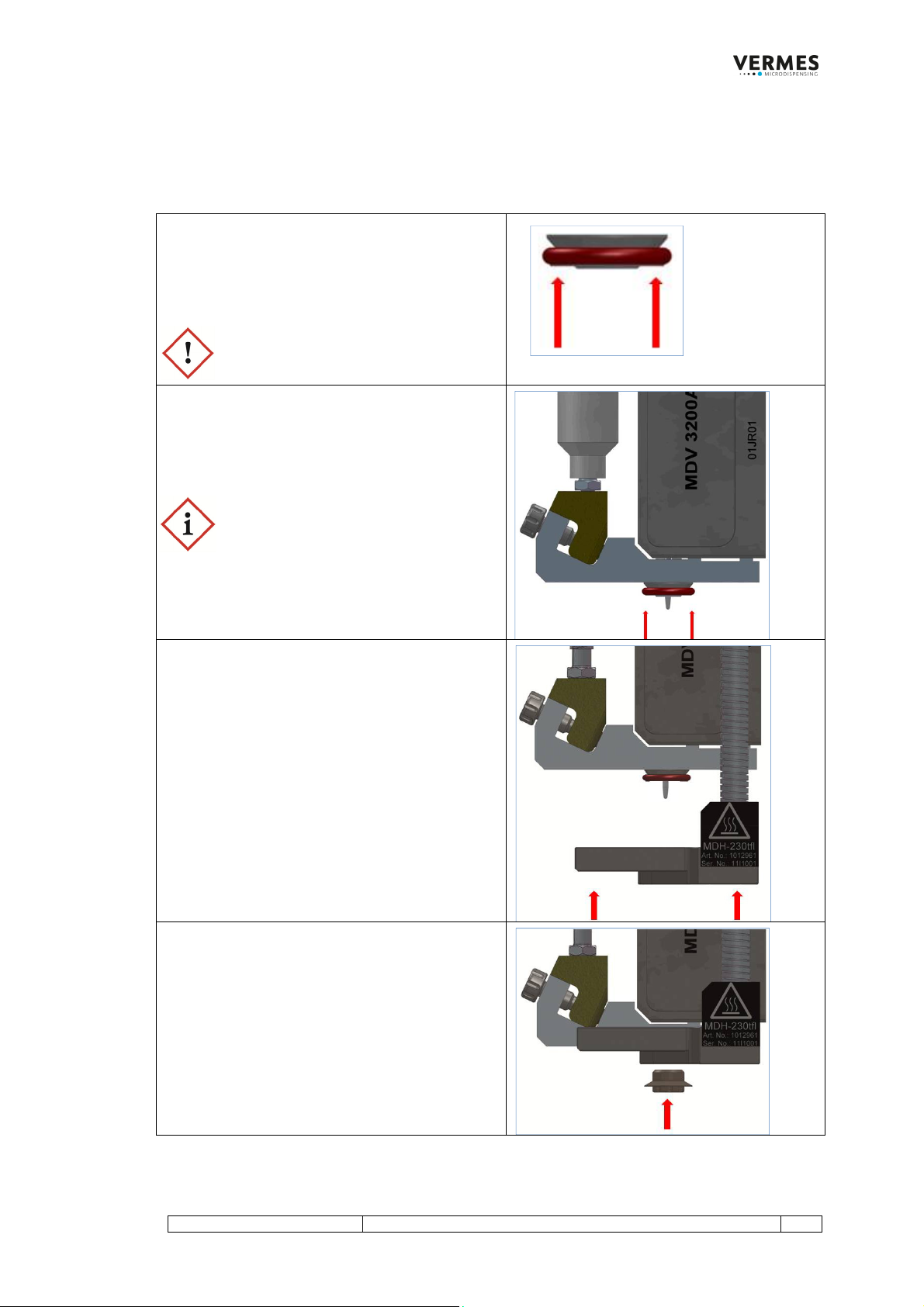

Thismanualshowsyouhowtosetupanapplicationforhotmeltdispensing.Thesetup

makesuseofaVERMESMicroDispensingSystemwithnozzleheaterandcartridgeheater.

CAUTION!(Hightemperatures)

Theheatersyouwillusecanreachtemperaturesofupto180°C.Forsuchhigh

temperaturesthereisadangerofsevereburnsandinjuries.Useheatresistantgloves.

1.1 GeneralIntroduction

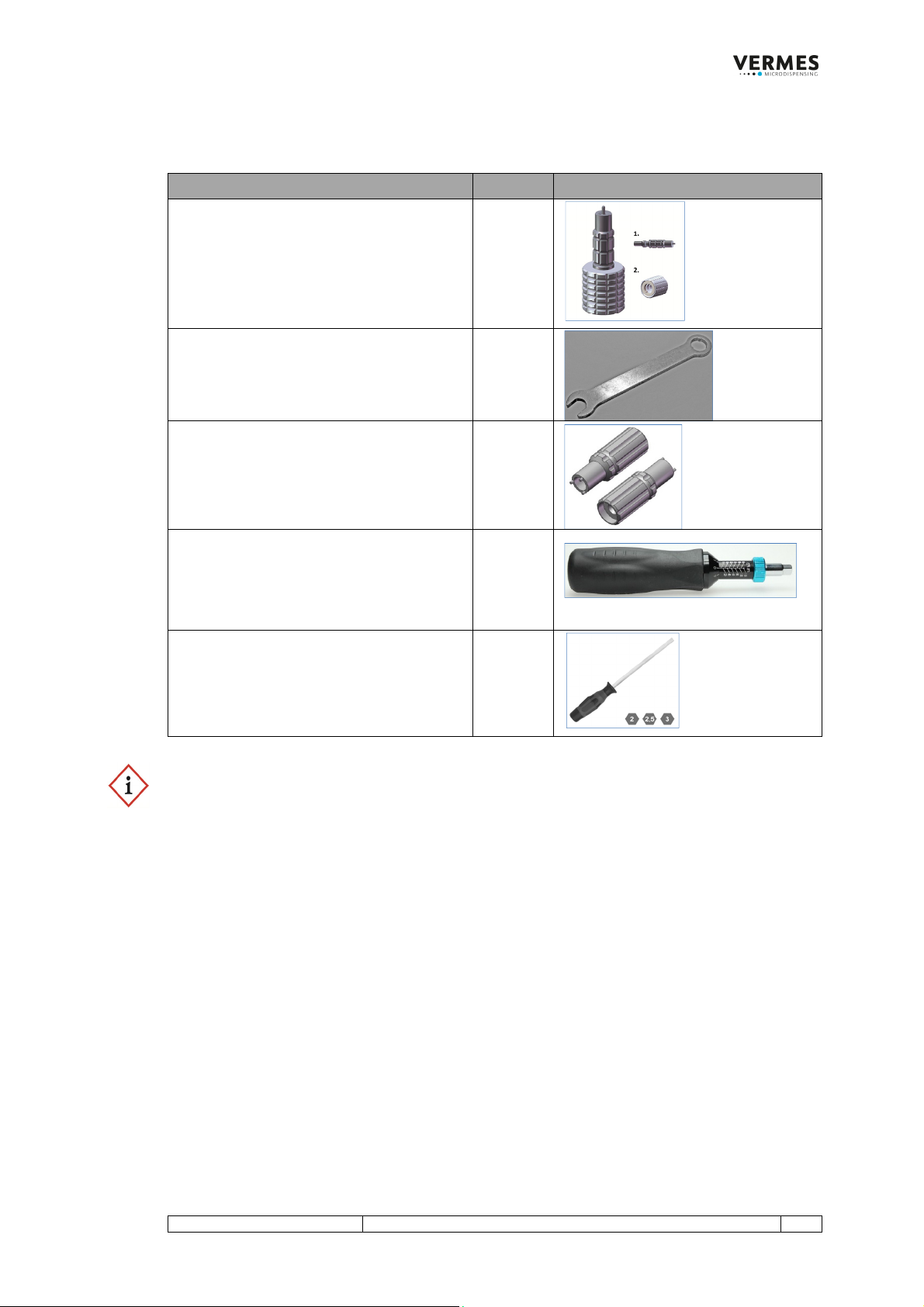

Thismanualexplainsstep‐by‐stephowtomountandworkwithanapplicationforthe

dispensingofareactivehotmeltadhesive.Itstartswiththenecessarypartsandtools;

followedbyanexplanationofhowtomountthenozzleandcartridgeheaters.Themanual

describeshowtodispenseandaddssometipsandtricksaboutcleaningthesystem

afterwards.Finallyaselectionofrecommendedfurtherreadingmaterialislisted.

Bewarethatsomepicturesmightdifferslightlyfromtheactualproduct.

Forbestresultsthedeadvolumeofthemediacarryingchannelsshouldbeassmallas

possibleandbemadeofthermallysimilarmaterialstoavoidtemperaturefluctuations.All

partsarechosensothattheyhaveagoodheatconductance,butarealsosufficientlyheat

resistant.Forthesamereasonitisimportanttouseavalvewithaircooling.

SincetheinternalcontroloftheheaterviaMDCcanonlyworkwithoneheater,youwill

needanexternalheatercontrol.YoucanusetheheatercontrolMHC3001(orderno.

1012948)foroneheaterortheheatercontrolMHC3002(orderno.1012949,seepicture

below)fortwoheatersanduseittocontrolbothheaters.Theadvantageofusingthe

MHC3002forbothheatersisthatthepossibleminimumdelaycanbesetshorter.