© Vestamatic GmbH

Art.-Nr.: 84501110 E1 • Vestamatic GmbH • Dohrweg 27 • D-41066 Mönchengladbach • www.vestamatic.com

IF SMI KNX 24VDC

Subject to modifications.

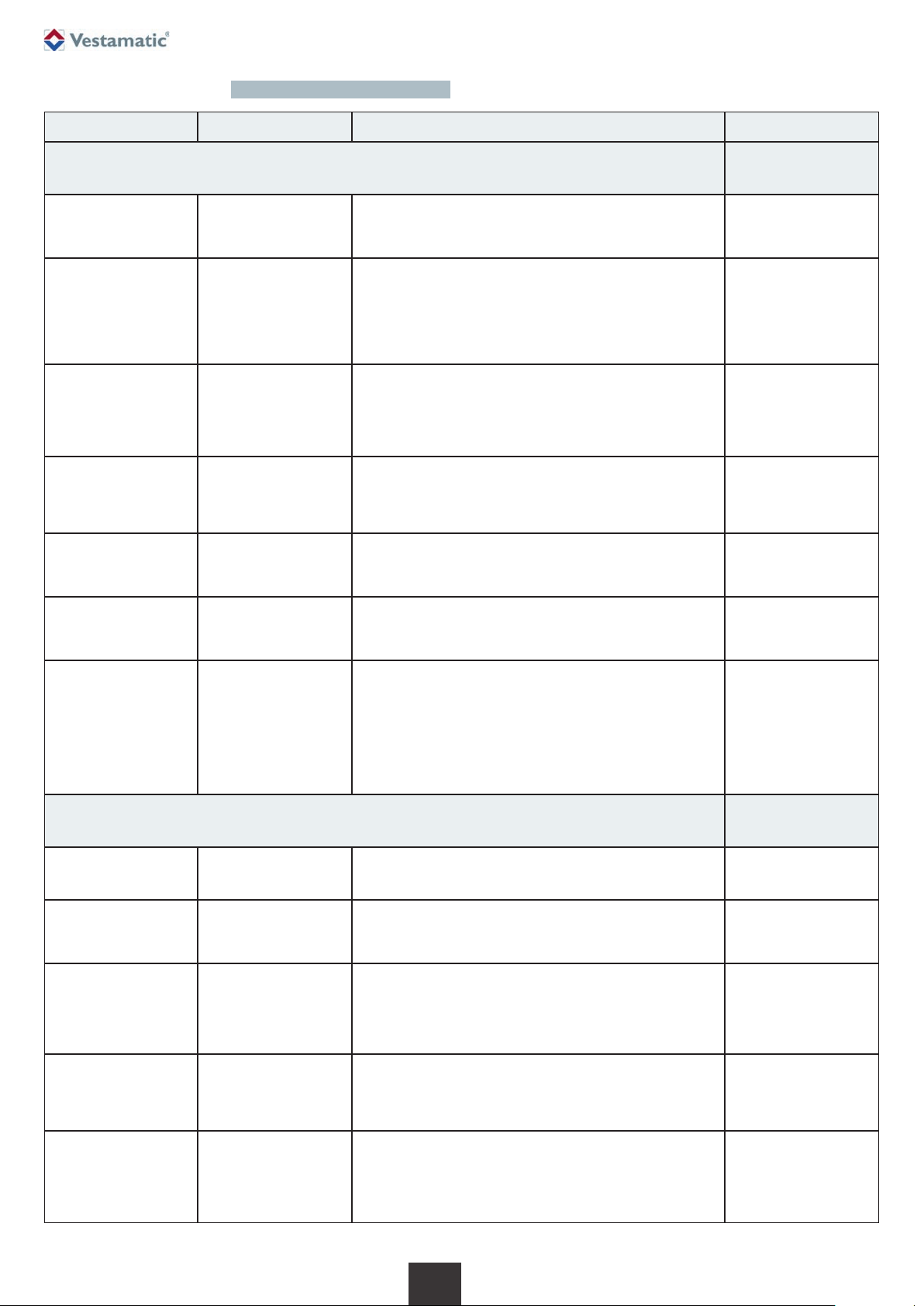

ETS communication objects

“Safety” object

You can switch the safety function on and off using this object. This object

can, for example, be connected to a wind monitoring device. Parameters

for each channel can be used to set whether the safety function is released

for the channel and how the individual drive should act when the safety

function is activated (UP, DOWN or no travel command). The object itself

works simultaneously on all channels for which the function is unlocked. If

the safety function is switched on and released via the parameters, all

incoming travel commands for the channel are locked. The command lock

is only overridden after the safety function has been switched off.

Object value “1”: safety function ON

Object value “0”: safety function OFF

“Travel command lock” object

You can switch the travel command lock on and off using this object. Via a

parameter, you can set for each channel whether the travel command lock

is released or locked for the individual channel. The object itself works

simultaneously on all channels for which the function is unlocked. If the

travel command lock is switched on and released via the parameters, all

incoming travel commands for the channel are locked. Any ongoing move-

ment at the time of activating the travel command lock is nevertheless still

brought to an end.

Object value “1”: travel command lock ON

Object value “0”: travel command lock OFF

“Up/Down travel, channel x” object (manual mode)

You can move the drive into the upper or lower end position using this

object.

If “blind” is parametrised as the shade type and the parameter “Adjust

upwards after manual downward travel” is set to released, a movement

occurs into the lower end position and is followed by an upward adjust-

ment according to the parametrised value for the upward adjustment in the

lower position. If the shade is already in the lower position, meaning that

the slat may only be closed by further travel, only the slat is closed and the

upward adjustment does not occur.

Object value “0”: travel into the upper end position

Object value “1”: travel into the lower end position

“Stop/Step travel, channel x” object (manual mode)

You can stop a movement or move the drive by a parametrisable increment

using this object.

Object value “0”: Stop or Step in direction of upper end position

Object value “1”: Stop or Step in direction of lower end position

“Sunshade, channel x” object (automatic mode)

Use this object to move the drive (similar to the “Up/Down travel, channel

x” object) into the upper or lower end position. In addition, after reaching

the lower end position, the drive moves (adjusts) in the direction of the

upper end position for a parametrisable distance.

This object is only visible if automatic mode is released for the channel.

Object value “0”: travel into the upper end position

Object value “1”: travel into the lower end position

“Automatic mode, channel x” object

Use this object to switch the operating mode of the actuator between auto-

matic and manual mode.Corresponding changes of operating mode can

also be carried out by other objects using the priority circuit of the operating

modes. For this see state administration and state table.

This object is only visible if automatic mode is released for the channel.

Object value “0”: automatic mode OFF

Object value “1”: automatic mode ON

“Position of sunshade (%), channel x” object

(Automatic mode or,if automatic deactivated, manual mode)

Use this object to position the shade height at a 1-byte value (0–255)

scaled to its maximum travel. A slat angle previously set automatically (%)

is subsequently restored.

If automatic mode is released for the channel, this object only causes a

setting in the case of activated automatic mode; alternatively the object

value is stored in the actuator and the position is only approached when

the automatic mode is activated again. If automatic mode is locked for the

channel, it is interpreted as a manual mode object.

Object value “0” (corresponds to 0%): travel to the upper end position

Object value “255” (corresponds to 100%): travel to the lower end position

Interim values are possible.

“Position of slat angle (%), channel x” object

(Automatic mode or,if automatic deactivated, manual mode –

only for blinds)

Use this object to position the slat angle at a 1-byte value (0–255) scaled

to maximum travel. The shade height remains unchanged in the process.

If automatic mode is released for the channel, this object only causes a

setting in automatic mode; alternatively the object value is stored in the

actuator and the position is approached when the automatic mode is acti-

vated again. If automatic mode is locked for the channel, it is interpreted

as a manual mode object.

This object is only visible when “blind” is parametrised as the shade type.

Object value “0” (corresponds to 0%): slat horizontal / open

Object value “255” (corresponds to 100%): slat closed

Interim values are possible.

“Status position of sunshade (%), channel x” object

Use this object to read out the current shade height (%). It is illustrated

scaled at a range of 0–255 (1 byte). The actuator transmits the status

spontaneously when the general parameter “Send status objects” is set to

“For status change”.

Object value “0” (corresponds to 0%): position of upper end position

Object value “255” (corresponds to 100%): position of lower end position

Interim values are possible.

“Status position of slat angle (%), channel x” object

(only for blinds)

Use this object to read out the current slat position (%). It is illustrated

scaled at a range of 0–255 (1 byte). The actuator transmits the status

spontaneously when the general parameter “Send status objects” is set to

“For status change”.

This object is only visible when “blind” is parametrised as the shade type.

Object value “0” (corresponds to 0%): slat position horizontal / open

Object value “255” (corresponds to 100%): slat position closed

Interim values are possible.

“Move to scene pos1/pos2, channel x” object (manual mode)

Use this object to move to positions pos1 or pos2 stored in the actuator.

With venetian blinds, shade height and slat angle are set; with roller shut-

ters only the shade height is set. Depending on the direction from which

the approach is made, the actuator for venetian blinds (using an appro-

priate movement strategy) ensures that, in the end, both shade height and

slat angle correspond to the values at the time the scene was stored.

Object value “0”: move to pos1

Object value “1”: move to pos 2

7/ 15

G