WARNING

Attempts to adjust and/or repair this product

by unauthorized or unqualified persons void the

product warranty and may cause damage to

equipment and serious injury or death to persons.

This product is a safety related component

intended for use in critical applications. The

improper application, installation or maintenance

of the valve or the use of parts or components not

manufactured by Emerson may result in a failure

of the valve.

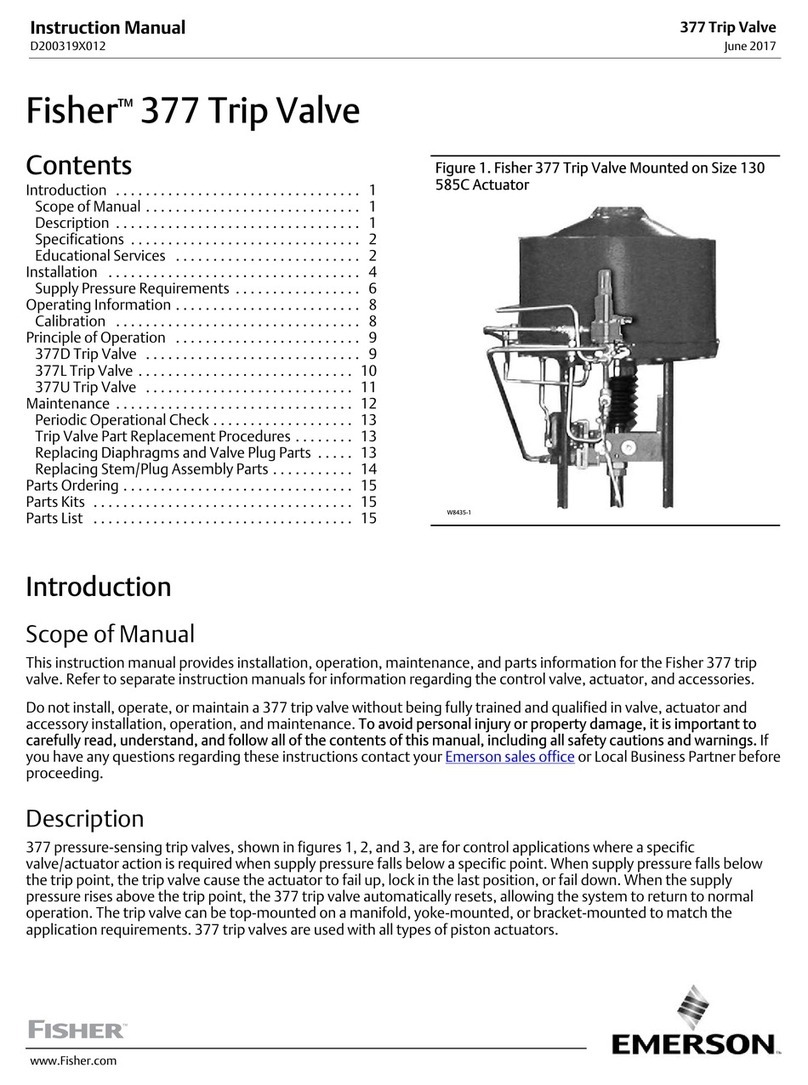

ANDERSON GREENWOOD SAFETY SELECTOR VALVES (SPOOL STYLE)

InstallatIon and operatIonal safety InstructIons

INSTALLATION

Many valves are damaged when first placed

in service because of failure to clean the

connection properly when installed. Before

installation, all flange faces or threaded

connections on both the SSV and the

connecting components (vessel, pipe or

pressure relief valve) must be thoroughly

cleaned of all dirt and foreign material.

Because foreign materials that pass into and

through the SSV can damage the seat, the

systems on which the valves are tested and

finally installed must also be inspected and

cleaned. New systems in particular are prone

to contain foreign objects that inadvertently get

trapped during construction and will destroy

the seating surface when the valve flows. The

system should be thoroughly cleaned before

the SSV is installed.

GENERAL

The intent of these instructions is to acquaint

the user with the storage, installation and

operation of this product.

This Safety Selector Valve (SSV) should only

be used in accordance with the applicable

operating instructions and within the application

specifications of the purchase order.

STORAGE AND HANDLING

Because cleanliness is essential to the

satisfactory operation and tightness of an SSV,

precautions should be taken during storage to

keep out all foreign materials. Inlet and outlet

protectors should remain in place until the

valve is ready to be installed in the system. It is

recommended that the valve be stored indoors

in the original shipping container away from dirt

and other forms of contamination.

The SSV should be handled with care and not

subjected to heavy shocks.

Before installation these instructions must be fully read and understood

© 2017 Emerson. All Rights Reserved.Emerson.com/FinalControl VCOSI-01063-EN 17/12

The gaskets used must be dimensionally correct

for the specific flanges. The inside diameters

must fully clear the valve inlet and outlet

openings so that the gasket does not restrict flow.

For flanged valves, draw down all connection

studs or bolts evenly to avoid possible distortion

of the valve body.

The SSV ‘s are shipped from the factory with

one side completely “isolated” and one side

“active”. The position indicator points to the

“active” side. Check that the “active” side is

correct for the initial installation and start-

up operation. See OPERATION below for

instructions to change.

The SSV is designed to minimize inlet pressure

loss to a pressure relief valve. To assure this is

accomplished follow these guidelines:

1. Connect the SSV as direct and close as

possible to the vessel being protected.

2. The SSV should be mounted vertically in an

upright position either directly on a nozzle

from the pressure vessel or on a short

connection fitting that provides a direct,

unobstructed flow between the vessel and

the valve.

3. The SSV should never be installed on a

fitting having a smaller inside diameter

than the inlet connection of the SSV.

The discharge piping should be carried by a

separate support and be properly braced to

withstand reactive thrust forces when the

pressure relief valve relieves. The SSV should

also be supported to withstand any swaying or

system vibrations.

Any installation, maintenance, adjustment, repair

or test, performed on the safety selector valve

must be done in accordance with the requirements

of all applicable Emerson Procedures and

Instructions as well as applicable National and

International Codes and Standards.

The information, specifications and technical data

(the “Specifications”) contained in this document

are subject to change without notice. Emerson

does not warrant that the Specifications are

current and assumes no responsibility for the

use or misuse thereof. The Purchaser should

verify that there have been no changes to the

Specifications prior to use.