7/6/2018 DRUM-LUG, MANUAL

Copyright 2018 Vestil Manufacturing Corp. Page 4 of 5

Using the lifter:

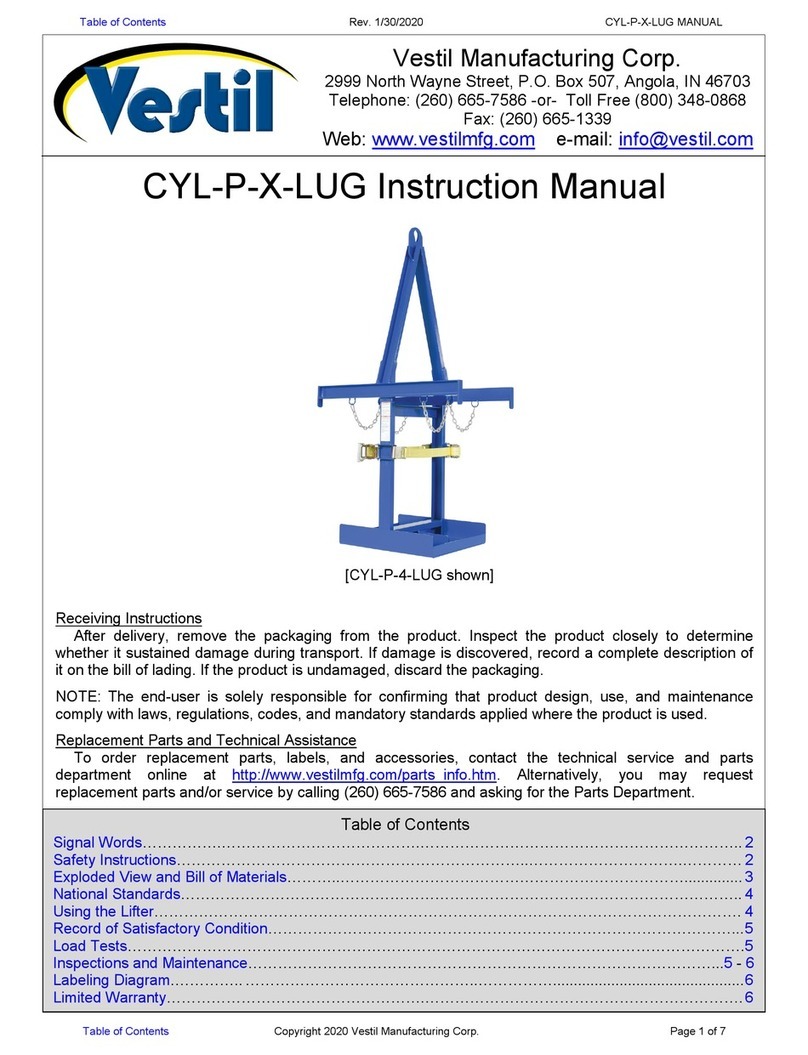

This product can be used either as a below-the-hook lifting device (attached to a hoist) or as a forklift attachment.

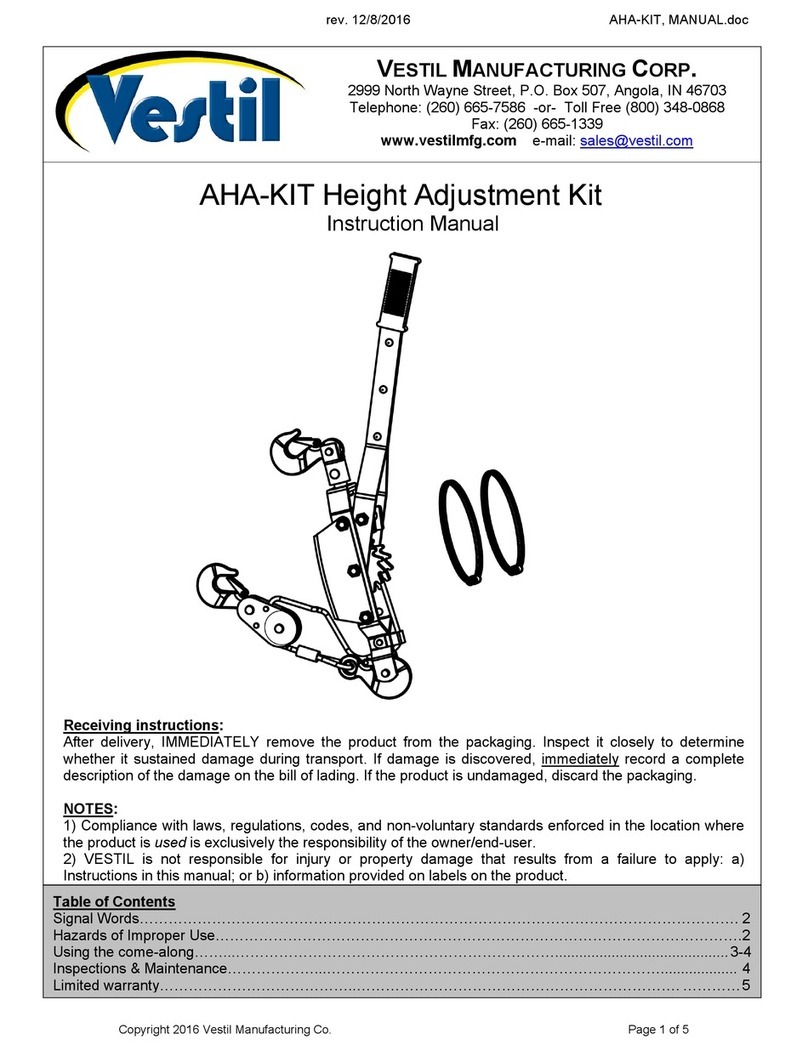

Step 1: Set the lifter next to the drum. The base

should contact the side of the drum.

Step 2: Tip the drum slightly away from the lifter.

Slide the base of the lifter under the drum. The side

of the drum should contact the back of the drum

cradle.

Step 3: Apply the ratchet strap. If the strap is not

long enough to wrap around the drum, then release

the spooling mechanism. Pull the release lever up

and hold it. Pull the strap away from the ratchet to

unspool strap and increase its length.

Step 4: Feed the hook at the end of the strap into

the hook slot in the frame. Move the ratchet handle

back-and-forth to tighten the strap against the drum.

Do not overtighten the strap, particularly when a

drum is plastic or fiber. Overtightening the strap

might damage (crack or rupture) the drum.

Step 5: Connect the lifter to a hoist or mount it on

the forks of your lift truck.

a. Hoist: attach the hoist hook to the shackle. Do

not side load the hoist! Side loading the hoist will

result in load swing as the lifter lifts off of the ground.

b. Forklift: drive the forks through both fork

channels. Drive forward until the forks wedge

against the tops and bottoms of the channels.

c. Attach the safety strap to the fork carriage. Wrap the strap around the carriage. Fasten the hook to the strap

or quick link (see exploded view on p. 3) without slack. The strap must not be able to disconnect from the

carriage during use.

Step 6: Raise the drum a few inches above the ground. Watch the drum and lifter for approximately 5 seconds to be

certain that the drum is secure. If the strap must be tightened, lower the lifter to the ground and then tighten the strap.

Step 7: Transport the drum to the desired location.

a. Overhead hoist: Lift the drum ~5-6 inches above the ground. Stand behind the drum. Grasp the handle

welded to the back of the cradle. Carefully direct the lifter to the desired location.. Minimize drum swing by

moving the hoist slowly.

b. Forklift: drive slowly, particularly while turning. Reduce speed during all turns. Apply the brakes gradually. The

lifter should not slide towards the tip of the forks

Step 8: Before lowering the drum, make sure that it is not swinging, spinning, etc. Slowly lower the drum until there is

slack in the hoist cable/chain or the forks are loose inside the fork channels. Disconnect the lifter from the hoist, or

demount the lifter from the forklift. Loosen the ratchet strap by pulling up on the release lever. Pull as much strap off of

the spool as necessary to unhook the strap from the frame.

Inspections & Maintenance:

Before using the lifter for the first time, make a written record of its appearance. Include observations about

shackle hardware, ratchet strap mechanism, the frame, handle, and fork channels (see diagrams in “Using the lifter”)..

Describe how much force is required to work the ratchet mechanism. Photograph each label and add the photographs

to the record. This record establishes “normal condition”. During future inspections, compare your observations to the

record to determine if the unit is in normal condition. DO NOT use the lifter unless it is in normal condition.

Examine the following elements before each use.

1. Shackles and shackle pin: Check for cracks, warps, and severe wear.

2. Ratchet and ratchet strap: Confirm that the ratchet works properly by moving the handle back-and-forth. The

release lever should automatically engage the teeth on the spool to prevent the strap from unwinding. Pull the

release level and unwind most of the strap. Check the strap for damage, such as cuts, tears, burns.

3. Frame, cradle, fork channels: Check welds and frame for breaks and severe rusting/corrosion. Remove

rust/corrosion with a brush or steel wool. Clean the area and apply touchup paint. The frame should be square

and rigid. Examine the frame around the hook slot and hole for the shackle pin for elongations, warps, etc.

4. Make a dated record of the inspection. Indicate whether each component inspected is in normal condition.

Describe repairs, adjustments and/or replacements. Only install manufacturer-approved replacement parts.

Pull release lever

up to release strap

Drum cradle

Hook fits

slot

Ratchet

handle

Fork

Fork

Handle

Tighten the

shackle pin

before each