Table of Contents Rev. 9/18/2023 FE MANUAL

Table of Contents Copyright 2023 Vestil Manufacturing Co. Page 6 of 8

INSPECTIONS

Inspections and repairs should only be performed by qualified persons. Compare the results of each

inspection to the RECORD OF SATISFACTORY CONDITION (the “RECORD”). Do not use the lifter unless all

parts are in satisfactory condition. Replace parts that are not in satisfactory condition before using the lifter

again. DON’T GUESS! If you have any questions about the condition of your boom, contact the TECHNICAL

SERVICE department. The phone number is provided on the cover page of this manual. Never make

temporary repairs of damaged or missing parts. Only use manufacturer-approved replacement parts.

Replace the entire unit if it cannot be restored to satisfactory condition.

WARNING

Immobilize the boom before conducting inspections and performing maintenance. If an inspection

reveals problems, restore the boom to satisfactory condition BEFORE using it again. DO NOT use a

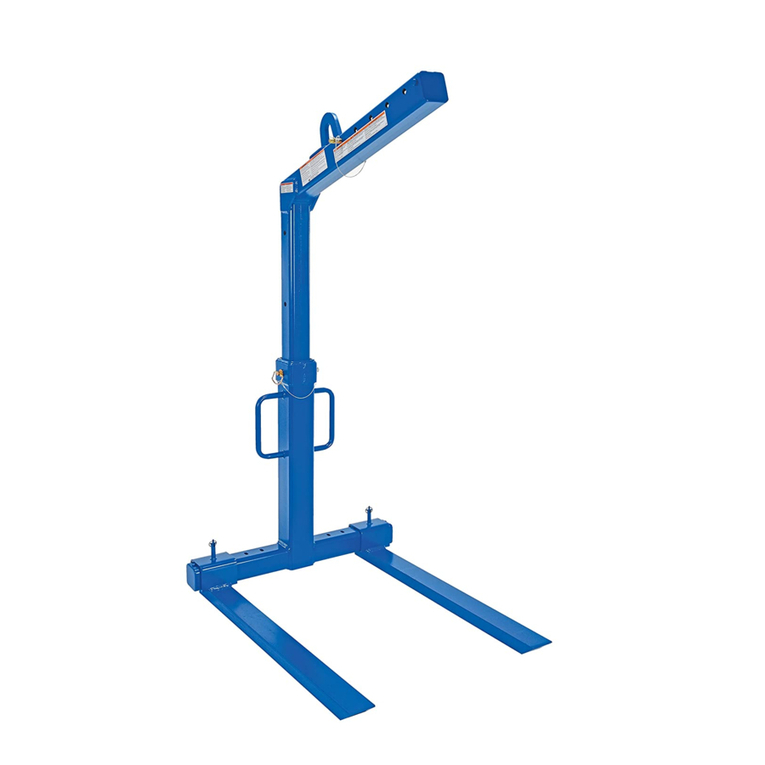

boom that is structurally damaged in any way. Structural damage includes, but is not limited to,

cracked welds, warping or deformation of the fork pockets, support leg, frame members, boom, or

boom sleeve.

1. Before each use –Visually examine each extension. Look for cracks, bends, significant

rusting/corrosion, and damaged welds (fusing the tin loop, tine brackets, or toe piece to the channel

piece.

2. Monthly inspection —At least once per month, and before using either of the extensions for the first

time, inspect the following:

Fork channel and toe piece (if applicable) —Fork channels should be square, rigid, and free of significant

rust or corrosion. Each toe piece should be solidly welded to the channel. Look for significant wear,

damage, or indications of metal fatigue to any portion of the fork channel or toe piece.

Tine loop (standard units) —Check all welds. Each loop should be straight, substantially parallel to the top

surface of the extension, and undamaged, i.e. no cracks, breaks, warps, etc.

Tine brackets and lock pin _(only -P models) —Both brackets must be solidly welded to the outer walls of

the fork channel. The lock pin should be straight and without bends, cracks, rust/corrosion, or significant

wear. Inspect the R-pin for cracks, rust/corrosion, and significant wear.

Labeling —Each pair of extensions should always be labeled as shown in the LABELING DIAGRAM on p. 7.

Replace any label that is damaged, significantly faded, or not easily readable from a reasonable distance.

3. Annual Lift Test –At least once per year, perform a LOAD TEST (p. 7) of the boom. Afterwards, conduct

a MONTHLY INSPECTION. Confirm SATISFACTORY CONDITION before returning it to service.

MAINTENANCE LOG

Implement a maintenance program that includes keeping a journal/log of all maintenance

performed on each fork extension to ensure that extensions remain in satisfactory condition. Apply the

following steps in conjunction with maintenance procedures applicable to fork truck attachments

provided in the most recent edition of ANSI/ITSDF B56.1.

Step 1: Tag the pair of extensions, “Out of Service.”

Step 2: Remove dirt and other matter from all surfaces.

Step 3: Conduct a Monthly inspection. If an extension has severe deformities, corrosion, rusting, or

excessive wear, DO NOT return the product to service. Tag it permanently out of service and render it

unusable.

Step 4: Perform all necessary adjustments, replacements and/or repairs. DO NOT modify a fork

extension.

WARNING

DO NOT return an extension to service until all necessary adjustments and repairs are complete! An

adjustment is a simple correction that restores SATISFACTORY CONDITION, such as tightening loose

fasteners or removing debris from surfaces. Repair means removal of worn parts and installation of

replacement parts, e.g. a new lock pin or R-pin. A “modification” is a change that alters an extension

from original, satisfactory condition, like bending the structural members or removing parts. NEVER

modify an extension without the express, written approval of Vestil. Modifications might make an

extension unsafe to use and automatically void the LIMITED WARRANTY on p. 8.

Step 5: Make a dated record of all repairs, adjustments, and replacements performed.