06 05/2022

VETRON 4000 - FLAT BED MACHINE - INSTRUCTION BOOK

01. PREFACE

01.01. SAFETY INSTRUCTIONS

-1-2

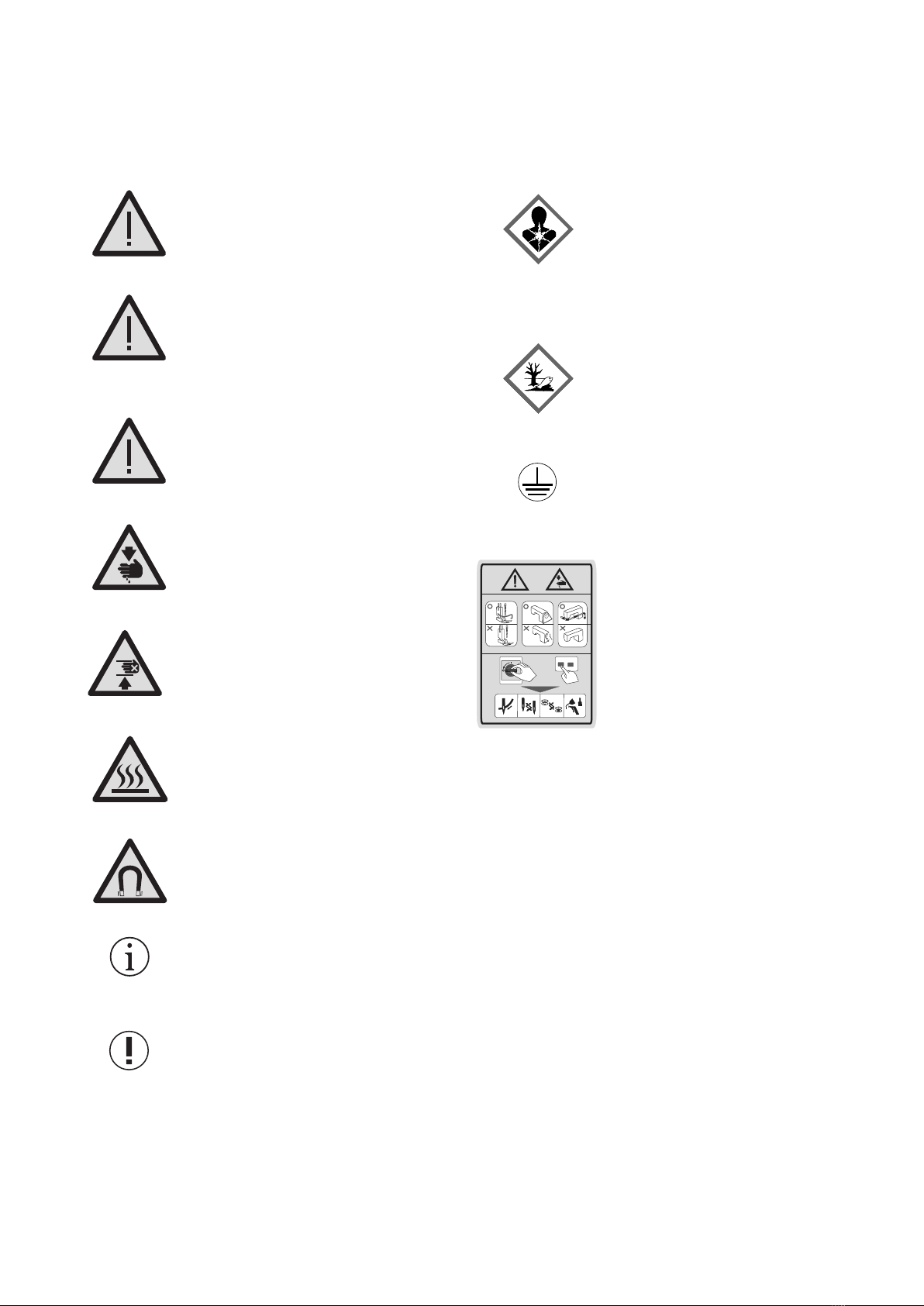

GENERAL SAFETY INSTRUCTIONS

This manual and the warning symbols on the machine should ensure the safe use of the machine, so that no accidents

and injuries may occur to you and others. Please read this instruction and also the safety instructions of the motor

manufacturer carefully.

»The machine must only be operated in accordance with its intended purpose (for example, sewing medium to heavy

materials such as jeans, leather, etc. NO tin!) and with the associated protective equipment. The relevant country-

specific safety regulations and technical data must also be observed.

»The machine should only be used in accordance with its intended purpose (eg sewing medium to heavy materials

such as jeans, leather, etc.) and with the associated protective equipment. The relevant country-specific safety

regulations and the technical data must also be observed.

»The machine should only be set up and operated in dry and well-kept rooms.

»Do not place the machines outdoors, next to radiators or heat source. The ambient temperature should not be lower

or higher than between 0° C to 45° C.

»The machine must only be commissioned after the relevant operating instructions have been taken into considera-

tion and by appropriately instructed operators.

»These instructions are to be stored at hand.

»The connection cable must be provided with a country-specific approved mains plug. The mains plug must only be

connected to grounded sockets. Here a qualified specialist is necessary.

»The machine must always have a grounding. Only over this is a normal operation of the machine to ensure.

»The danger and safety instructions attached to the machine must be followed.

»When replacing sewing tools such as needle, sewing foot, stitch plate, feed dog or bobbin, when threading, when

leaving the workplace and during maintenance, etc., the machine must be disconnected from the mains.

Press the main switch or pull out the mains plug.

»Machines with compressed air components must be disconnected from the compressed air supply and the residual

pressure released before repair or maintenance work. Exceptions to this are performance tests or specific settings.

»Repairs and all maintenance work should only be carried out by qualified personnel or appropriately instructed per-

sons.

»Work on electrical equipment must only be carried out by qualified specialists.

If errors are detected, stop the machine immediately.

»Work on parts and equipment that are live is not permitted. The machine must be disconnected from the mains.

»Modifications or modifications to the machine must be carried out in compliance with all relevant safety regulati-

ons. The manufacturer assumes no responsibility for damage caused by changes or modifications.

»For repairs, only spare parts approved by VETRON may be used. In case of infringement the guarantee expires.

»The machines are to be used only for the purpose intended.

»If oils, greases, etc., used for the machines and accessories, get in your eyes or on your skin, or should you swallow

any of these fluids, wash them immediately and thoroughly, or seek medical attention immediately.

»Commissioning of the machine is prohibited until it has been determined that the entire sewing unit complies with

the provisions of the EC directive and the declaration of conformity has been created.