IMPORTANT SAFETY INSTRUCTIONS

CAUTION - To reduce risk of electrical shock:

- Donotdisassemble.Donotattemptrepairsormodications.Refertoqualiedservice

agenciesforallserviceandrepairs.

- Donotusethisproductinanareawhereitcanfallorbepulledintowaterorotherliquids.

- Donotreachforthisproductifithasfallenintoliquid.

- Use compressors with 12-Volt DC systems only.

- Thisproductshouldneverbeleftunattendedduringuse.

WARNING - To prevent injury:

- Neverallowchildrentooperatecompressors.Closesupervisionisnecessarywhenthis

compressor is being used near children.

- CompressorswillbecomeveryHOTduringandimmediatelyafteruse.Donottouchanypartof

the compressor with bare hands during and immediately after use.

- Donotusethisproductnearamesorexplosivematerialsorwhereaerosolproducts

are being used.

- Donotoperatethisproductwhereoxygenisbeingadministered.

- Do not pump anything other than atmospheric air.

- Neverusethisproductwhilesleepyordrowsy.

- Donotuseanytoolsorattachmentswithoutrstdeterminingmaximumairpressurefor

that tool or attachment.

- Neverpointanyairnozzleorairsprayertowardanotherpersonoranypartofthebody.

- Each444CaircompressorisequippedwithanAutomaticResetThermalProtector,andcan

automaticallyrestartafterthethermalprotectorresets.Alwayscutopowersourcewhen

thermalprotectorbecomesactivated.

- Wear safety glasses or goggles when installing this product.

- Useonlyinwellventilatedareas.

INSTALLATION

Pleasereadandfollowtheinstallationinstructionscarefullytoavoidinjuryordamagetothe

compressorandyourvehicle.

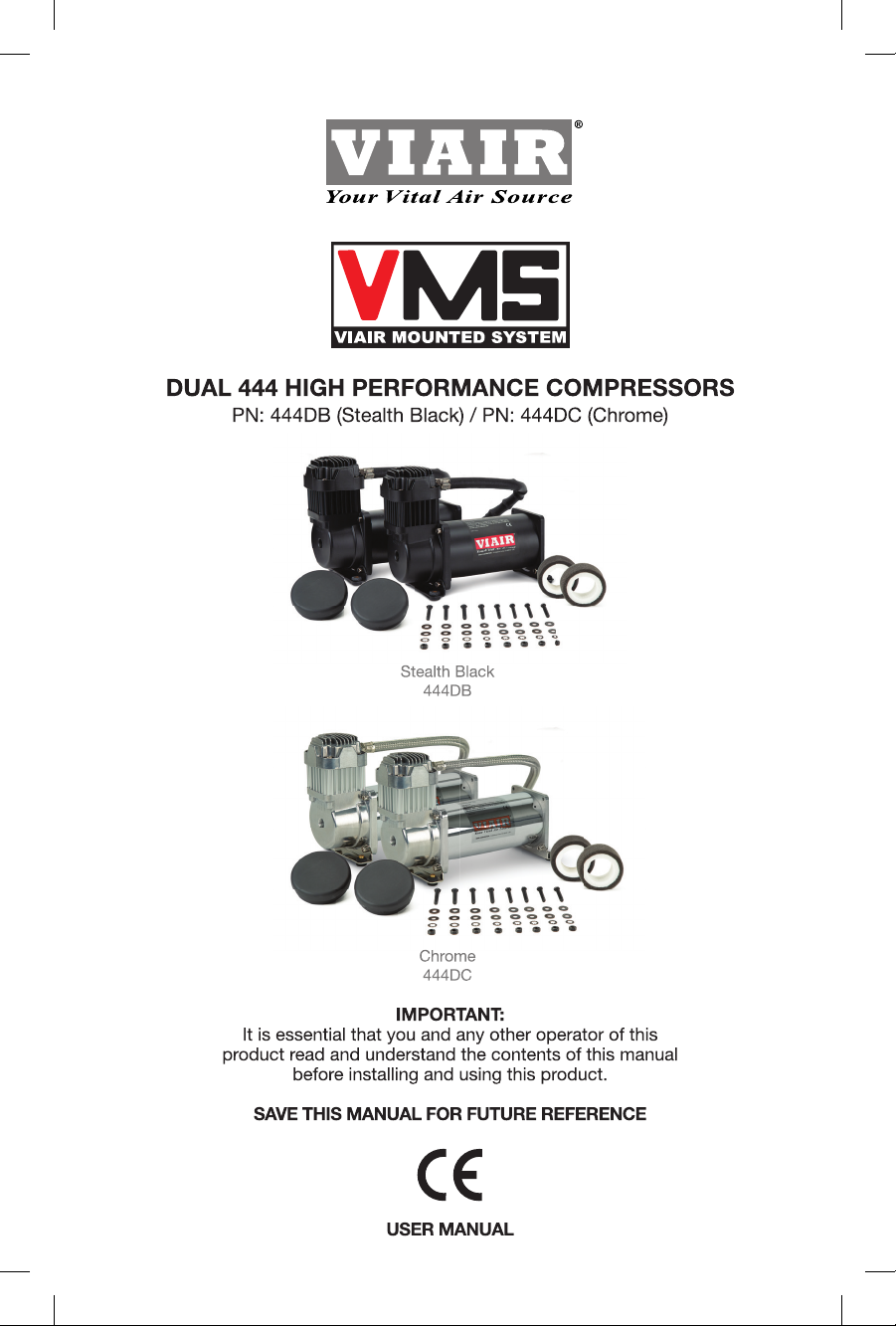

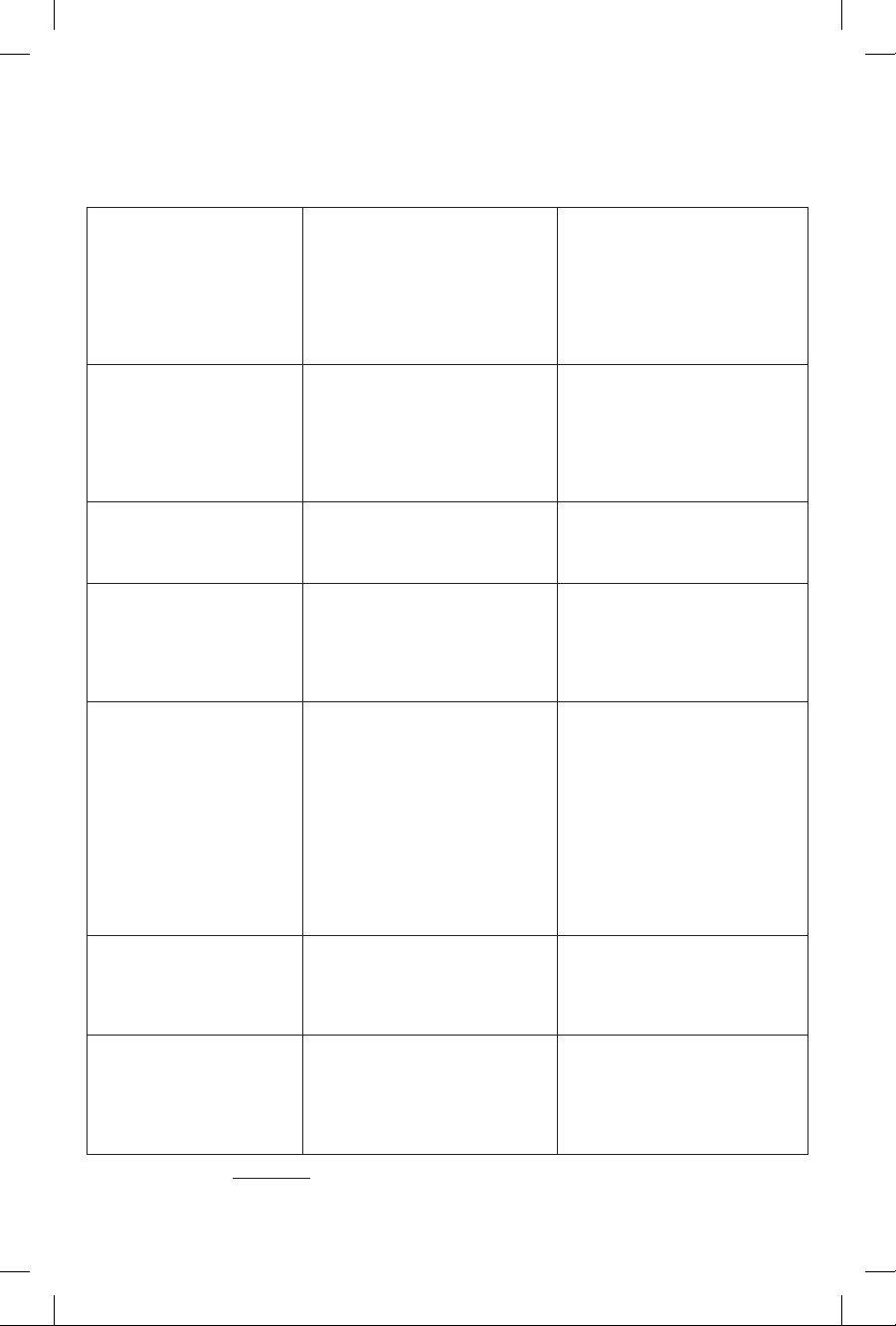

Eachofouraircompressorsandpartshavebeencarefullyproducedandpackaged.Beforeyou

begininstallation,pleasefamiliarizeyourselfwithInstallationPartsList(Fig.1)ofthismanual.

Guidelines for Selecting Mounting Location:

The selection of proper mounting location for your air compressor will help ensure a long and trouble

freecompressorservicelife.Pleasepaycloseattentiontothefollowingguidelines:

1. SelectaFLATANDSECURElocationwherethecompressorscanbemounted.

2. Tomaximizeaircompressorperformance,locatecompressorasCLOSETOTHEBATTERYas

possiblesothatthelengthofthepositiveleadwirerequiredisataminimum.

3. ChoosemountinglocationthatisascoolaspossibleandAWAYFROMHEATSOURCES.

Thecoolertheambienttemperature,thelesschancethecompressorwilloverheat.

4. Thesecompressorsaremoisture&splashresistant,butNOTWATERPROOF.

Do not mount compressor in locations where the unit is likely to come in contact with water.

5. Forremoteltermounting(soldseparately),selectcompressormountinglocationwhereairline

canberoutedfromcompressorairinlettoremoteinletairlter.MakesureRemoteInletAirFilter

islocatedinadrylocation,awayfromtheelements.

7. Ifitisnecessarytomountaircompressorsfurtherawayfromthebattery,suchasinside

yourvehicleoronthechassisofapickup,useaminimum8AWGpositiveleadwirefor

remote installation.

8. Donotmountcompressornearareaswhereammableliquidsarestored.

9. VIAIR®suggeststheuseofa40-Ampratedrelaywitheachcompressor(notincludedwiththiskit).

10.VIAIR®alsosuggeststheuseofa200PSImaximumpressureswitchtoregulateon&o

pressures.Pressureswitchisnotincludedwiththiskit.

USER MANUAL

DUAL 444C HIGH PERFORMANCE COMPRESSORS