USER MANUAL

65C Air Compressor Kit

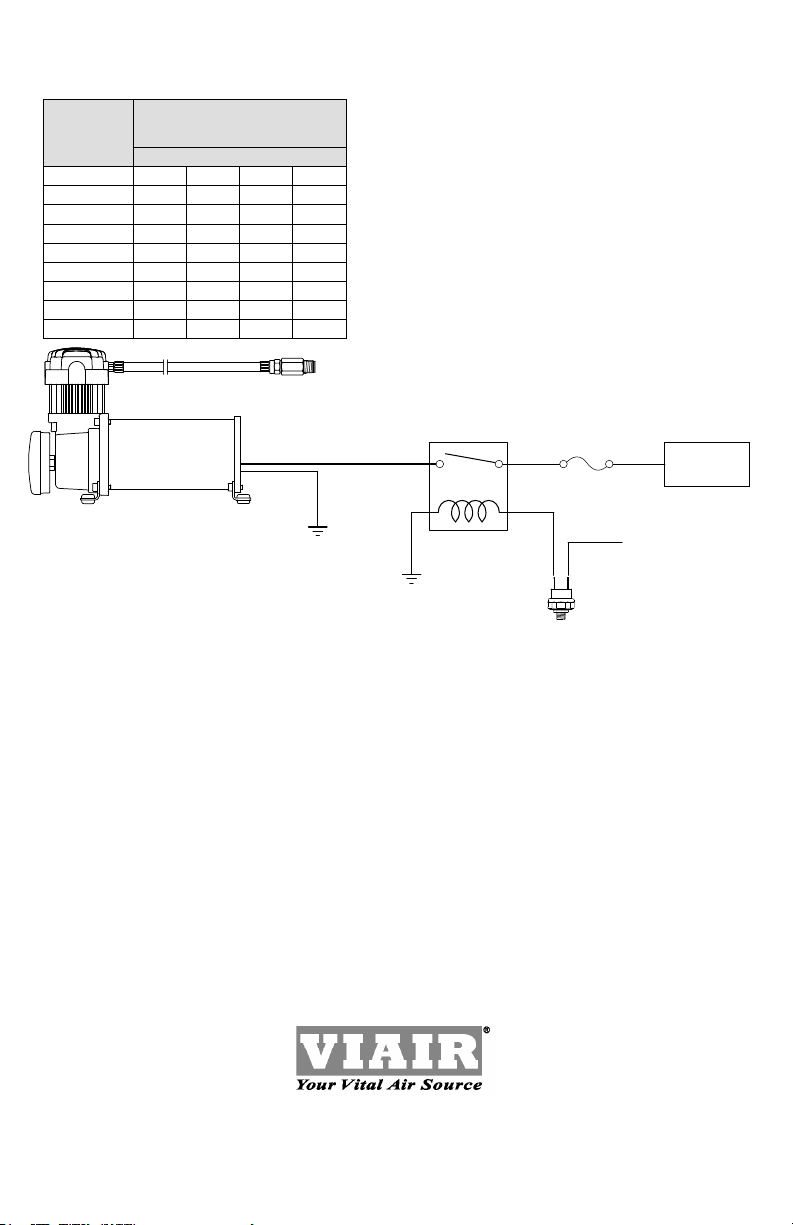

COMPRESSOR APPLICATION GUIDE

Toensurethatyougetthehighestlevelofsatisfactionfromyourcompressorperformance,referto

information below:

VIAIR® COMPRESSOR REFERENCE CHART

COMPRESSORSERIES MAX.WORKING DUTYCYCLE

PRESSURE (100PSI@72°F)

065SERIES 80PSI 15%

090SERIES 120PSI 9%

092SERIES 120PSI 9%

095SERIES 120PSI 9%

097SERIES 130PSI 10%

098SERIES 130PSI 10%

100SERIES 130PSI 15%

250IGSERIES 150PSI 100%

275SERIES 150PSI 25%

280SERIES 150PSI 30%

325SERIES 150PSI 33%

330IGSERIES 150PSI 100%

350SERIES 150PSI 100%

380SERIES 200PSI 100%

55%@200PSI

400SERIES 150PSI 33%

420SERIES 150PSI 33%

425SERIES 175PSI 33%@175PSI

50%

444SERIES 200PSI 100%

50%@200PSI

450SERIES 150PSI 100%

450IGSERIES 150PSI 100%

460SERIES 150PSI 100%

480SERIES 200PSI 100%

50%@200PSI

485SERIES 200PSI 100%

100%@200PSI

ABOUT COMPRESSOR DUTY CYCLE:

Duty cycle refers to the amount of time a compressor can be

operatedinagiventimeperiodat100PSI,andastandardambienttemperatureof72°F.Itis

commonlyexpressedinpercentageformat:Compressorontime÷(ontime+otime)=Duty

Cycle%.

ONE-HOUR DUTY CYCLE MINUTES ON /

(100PSI@72°F) MINUTES OFF

9% 5min.On/55min.O

10% 6min.On/54min.O

15% 9min.On/51min.O

20% 12min.On/48min.O

25% 15min.On/45min.O

30% 18min.On/42min.O

33% 20min.On/40min.O

50% 30min.On/30min.O

100% 1HourRunTime

NOTE:Allcompressors,regardlessofrateddutycycle,requiresucientresttimeinbetween

cyclestoallowforpartialorcompleteheatdissipation.Heatdissipationratesmayvarydepending

on ambient temperatures and operating conditions.

ABOUT RATED WORKING PRESSURE:

Toensuretroublefreeservicelifeofyourcompressor,alwaysoperatecompressorwithinrated

workingpressureofthecompressor.Neveruseapressureswitchwithahighercut-opressure

thancompressor'sratedworkingpressure.