TLC PRO COMPRESSOR KIT

USER MANUAL

OPERATING INSTRUCTIONS

Your TLC PRO is powered via the Battery Clips or Terminal Rings, and can be used as a portable or hard-

mounted to your vehicle using the respective attachments. To avoid draining your battery and assure the

compressorisgettingtheproperamperage,makesureyourvehicle’sengineisrunningduringoperation,

especially if using for a prolonged period of time. Do not connect the Red Clip or Red Terminal Ring to any

powersourceotherthanthePositive(+)Terminalofyourvehicle’sbattery.

1 - CONNECTING TO THE BATTERY USING THE 2-PIN SAE BATTERY CLIPS

TheBatteryClipsoeraexiblewayofpoweringyourcompressorfromanyvehiclebysimplyclipping

them onto the battery terminals.

a.MakesurethecompressorswitchisintheOFF(O)position.

b.Makesurethevehicle’sengineandignitionareo.

c. Connect the Red Clip to the Positive (+) terminal of your battery.

d.ConnecttheBlackCliptotheNegative(-)terminalofyourbattery,orothergroundsource.

e.Starttheengine.

2 - CONNECTING TO THE BATTERY USING THE 2-PIN SAE TERMINAL RINGS

The Terminal Rings allow you to mount the compressor permanently to a vehicle and also provide a more

practical way of using it as a portable.

a.Makesurethevehicle’sengineandignitionareo.

b. Install the Red Terminal Ring on the Positive (+) terminal post of your battery, this can be done by

removing the nut that holds the clamp in place, installing the terminal ring, and re-tightening the

nut.Refertoyourvehicle’sowner’smanualforhelpifneeded.

c.InstalltheBlackTerminalRingontheNegative(-)terminalpostofyourbatteryorother

ground source.

d.Connectcompressorpowercordtothe2-PinSAEterminal.

e.Starttheengine.

3 - USING THE COMPRESSOR

Nowthatyourvehicleisrunning,you’rereadytooperateyourTLCPRO.Makesuretheairlterisinstalled

as this is a vital component to the longevity of your compressor.

a.ConnecttheCoilHosetotheQuickConnectStudonyourTLCPRO.

b.ConnecttheTLCInatororBlowGuntotheotherendoftheCoilHose.

c.TurnonyourTLCPRObyippingtheswitchtotheON(I)position.

d.Thecompressorwillrunforafewmomentsandautomaticallyshutowhenthereservoirhas

beenlledtomaxpressure.

e.You’renowreadytoperformyourpneumatictasks!

HARD-MOUNT INSTALLATION INSTRUCTIONS

a. Refer to section 2 of Operating Instructions and connect the battery Terminal Rings to your

vehicle’sbattery.

b.SelectaFLAT,UPRIGHT,ANDSECURElocationwherethecompressorcanbemounted.

c.Routethecompressor’spowercordtotheterminalringsandconnectusingtheSAEplug.

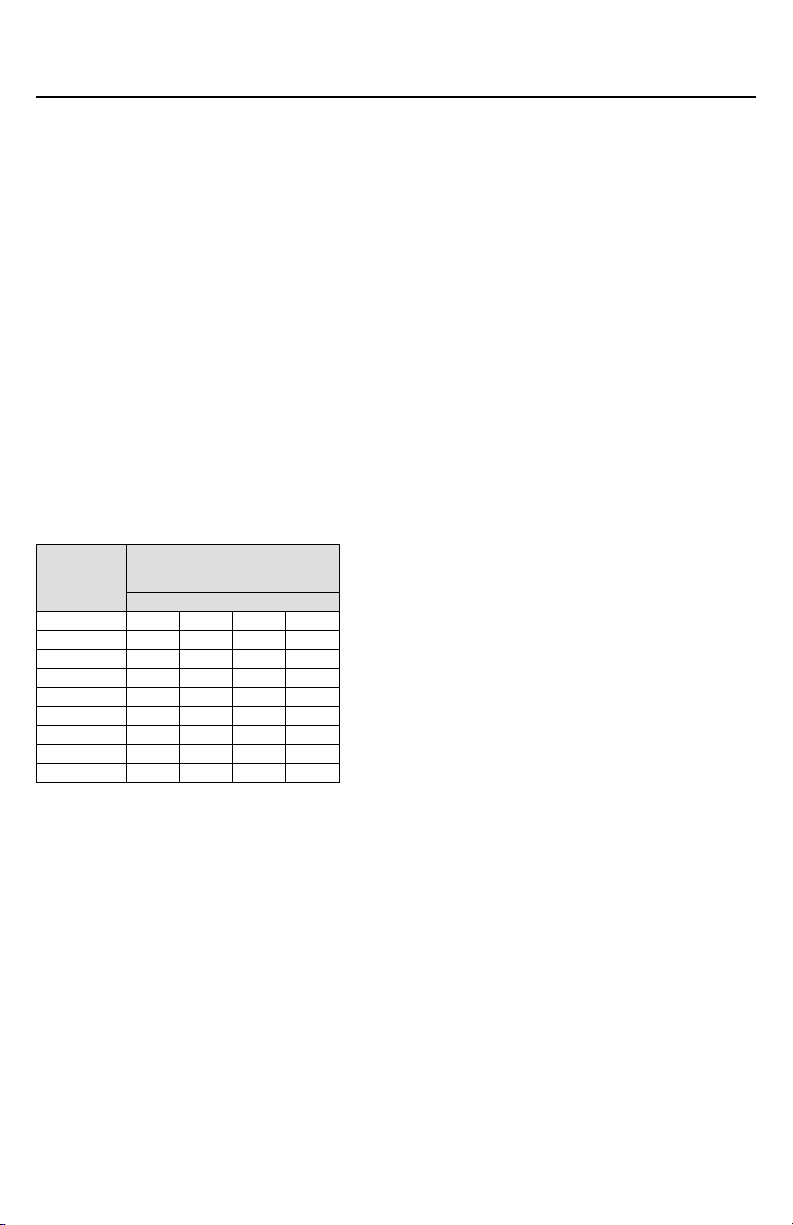

d.Ifit’snecessarytomountthecompressorinaplacebeyondthepowercord’sreachtothe

Terminal Ring attachment, refer to the amp draw chart on the last page of this manual and use

appropriategaugewiretoextendyourbatteryTerminalRingattachments.Whenindoubt,always

usethenextlargerwiresize.

IMPORTANT NOTES:

a.Ifmountingintheenginecompartment,openyourhoodtoallowmaximumcoolingofthe

compressor unit during prolonged use. The cooler the ambient temperature, the less chance the

compressor will overheat.

b.Thiscompressorismoisture&dustresistant,butNOTDIRTORWATERPROOF.Donotmount

compressorinlocationswheretheunitislikelytocomeincontactwiththeelements.

c.Ifit’snecessarytomountthecompressorinaplacebeyondthepowercord’sreachtothe

Terminal Ring attachment, refer to the amp draw chart on the last page of this manual and use

appropriategaugewiretoextendyourbatteryTerminalRingattachments.Whenindoubt,always

usethenextlargerwiresize.