1

04/06/04 LIT-H200X-E02 H200.doc

ELECTRONIC HUMIDISTAT: H200

•ONE OR TWO STAGES

DESCRIPTION

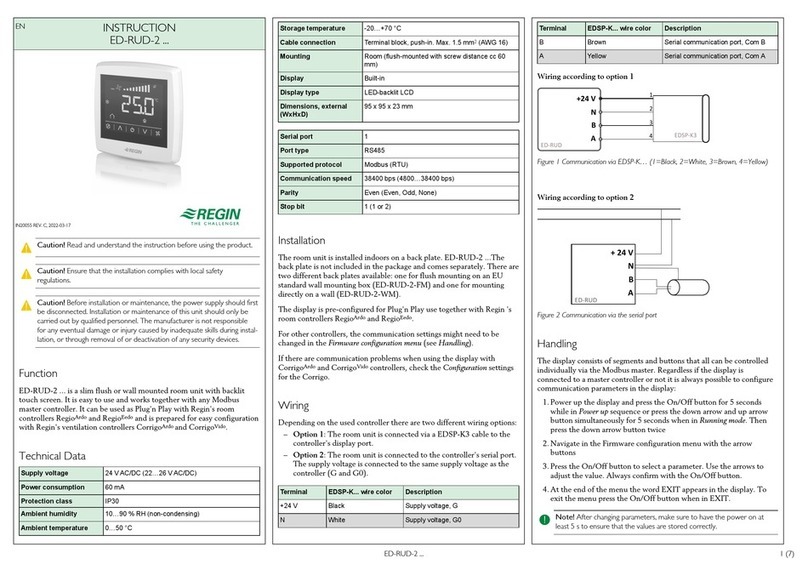

The H200 series low voltage, microcomputer-based PI

(proportional and integral) humidistats are designed for

accurate humidification and/or dehumidification control

in non-corrosive commercial applications such as:

hospitals, schools, office buildings, retail stores,

museums, computer rooms, etc.

The H200 series is available with one or two outputs

for maximum flexibility. Outputs can be of the following

type: proportional, on/off, and pulse width modulation

(PWM). In addition, a wide variety of mounting

configurations is available. Sensing options include

remote duct and room as well as integral room and

duct.

Setpoint adjustment can be either concealed or

exposed, adding even more versatility to the product.

Exposed models feature internally selectable minimum

and maximum setpoint knob stops.

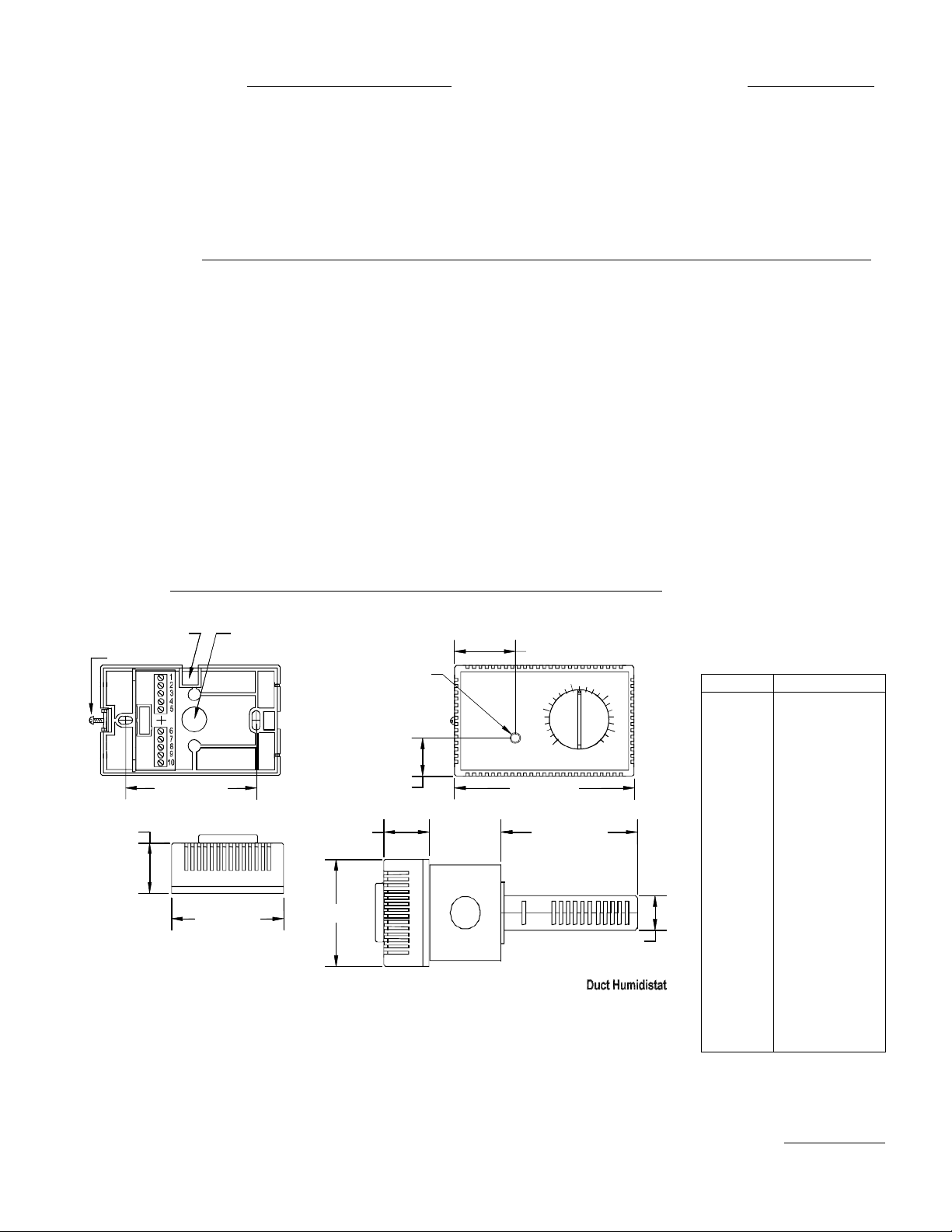

In order to facilitate periodic recalibration, the H200

series contains a unique autocal key, which permits

instant recalibration (see dimension drawing on page 5

for location).

Each humidistat is computer calibrated and factory

programmed with default parameters. All control

parameters (such as proportional band, stage

differential, etc.) may be changed in the field with the

H263 programming tool without having to remove the

thermostat cover. The H263 also doubles as a

diagnostic tool and indicates the status of all the inputs

and outputs, and will reduce troubleshooting time by

quickly identifying the specific problem.

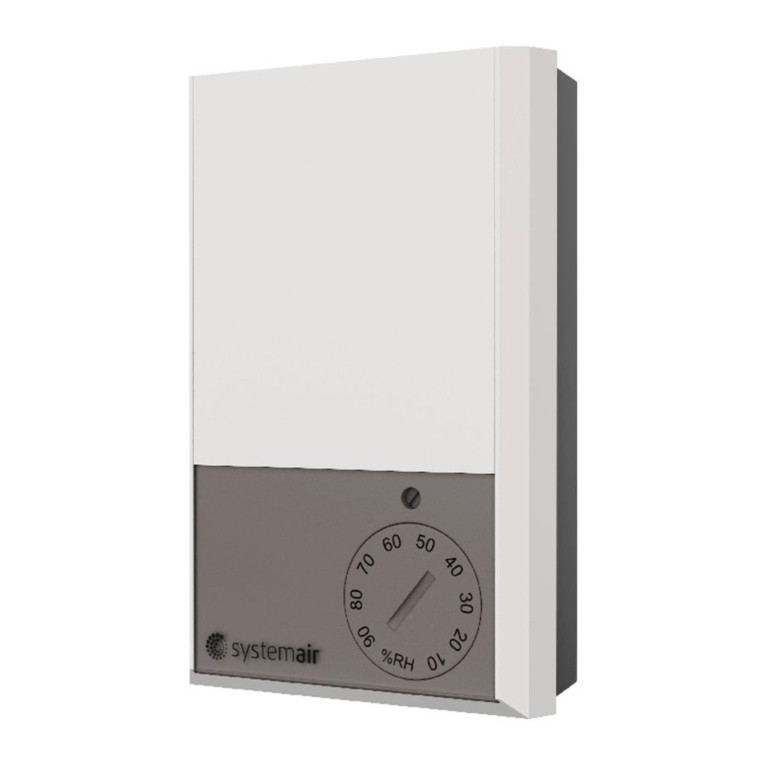

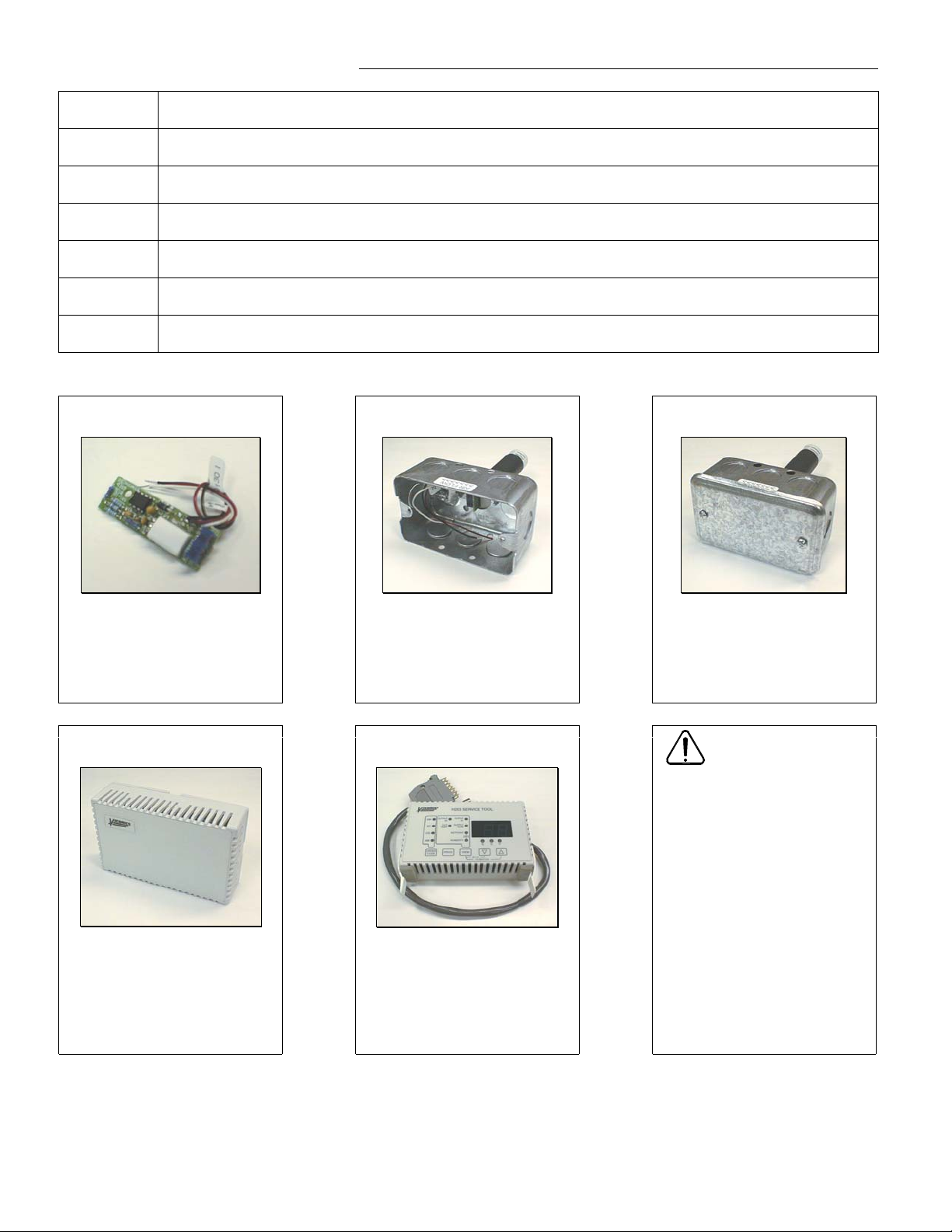

Fig.1: Wall mounted humidistat

Features Benefits

•Microcomputer-based design with PI algorithm ⇒Exceptional accuracy

•One or two outputs ⇒Controls humidification and dehumidification equipment

•On/off and/or proportional outputs ⇒Greater flexibility

•Direct or reverse acting outputs ⇒Controls humidification and dehumidification equipment

•Integrated and remote sensing ⇒Larger choice of mounting options

•Autocal button ⇒Permits instant recalibration

•Concealed or exposed set point ⇒Can be used in a large variety of environments

•Ouput signal to digital indicating devices ⇒Increases functionality of product

•Optional H263 diagnostic tool with digital display ⇒Simplifies troubleshooting

•Sensor failure protection ⇒Prevent water dammage

•CE approved ⇒Can be sold in European markets