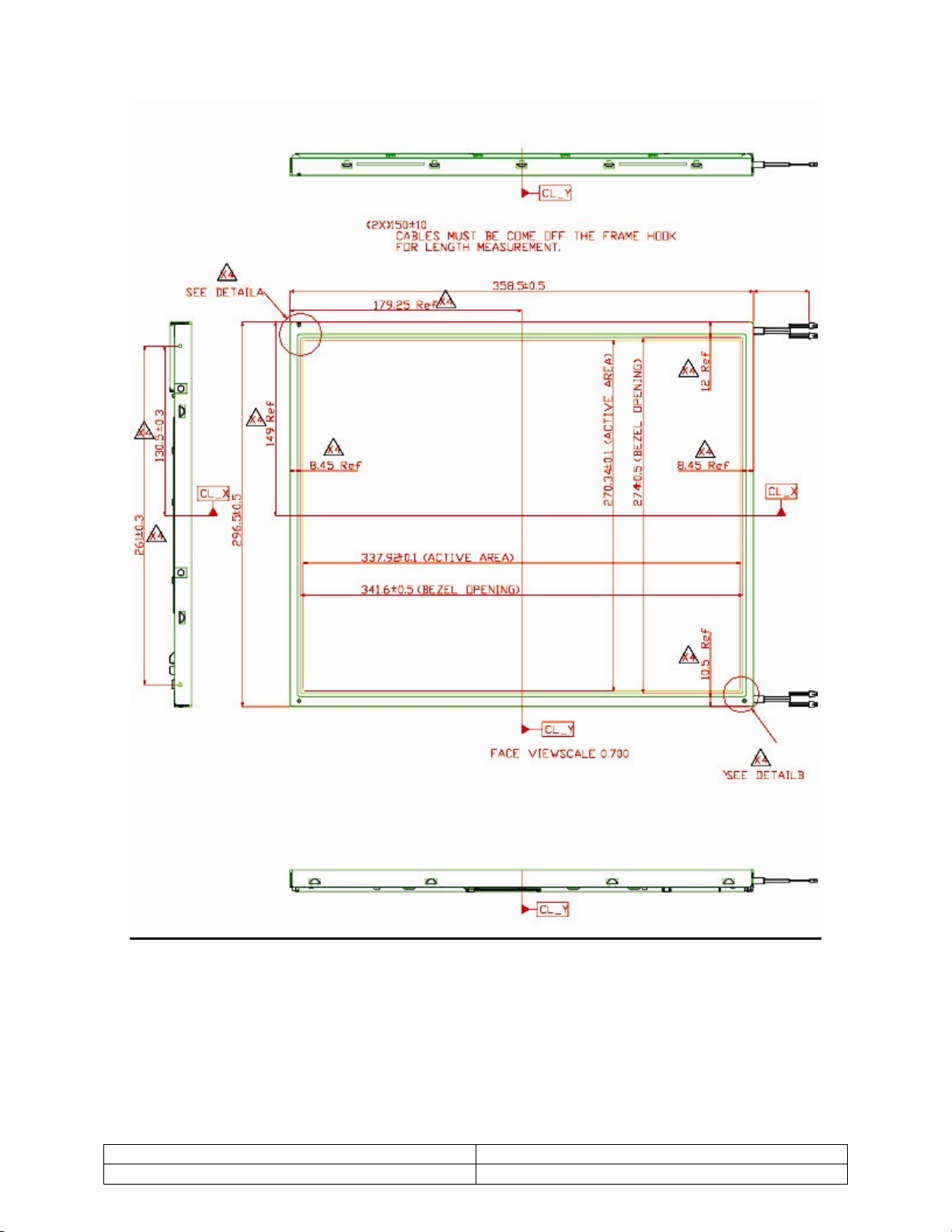

5. Module Connector P in Configuration

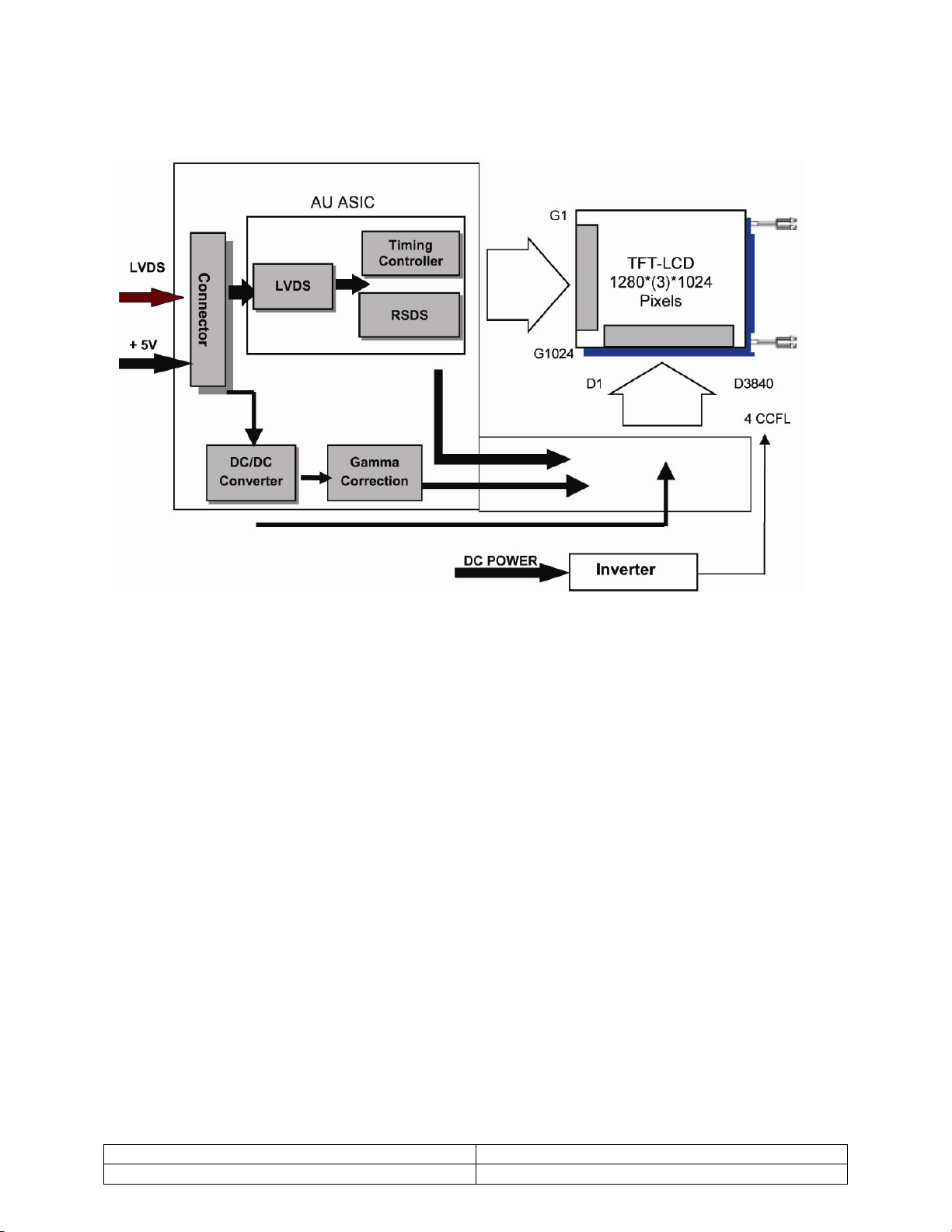

The module using a pair of LVDS receivers SN75LVDS82 (Texas Instruments) or compatible.

LVDS is a differential signal technology for LCD interface and high peed data transfer

device. Transmitter shall be SN75LVDS83 (negative edge sampling) or compatible. The first

LVDS port (RxOxxx) transmits odd pixels wile the second LVDS port (RxExxx) transmits

even pixels.

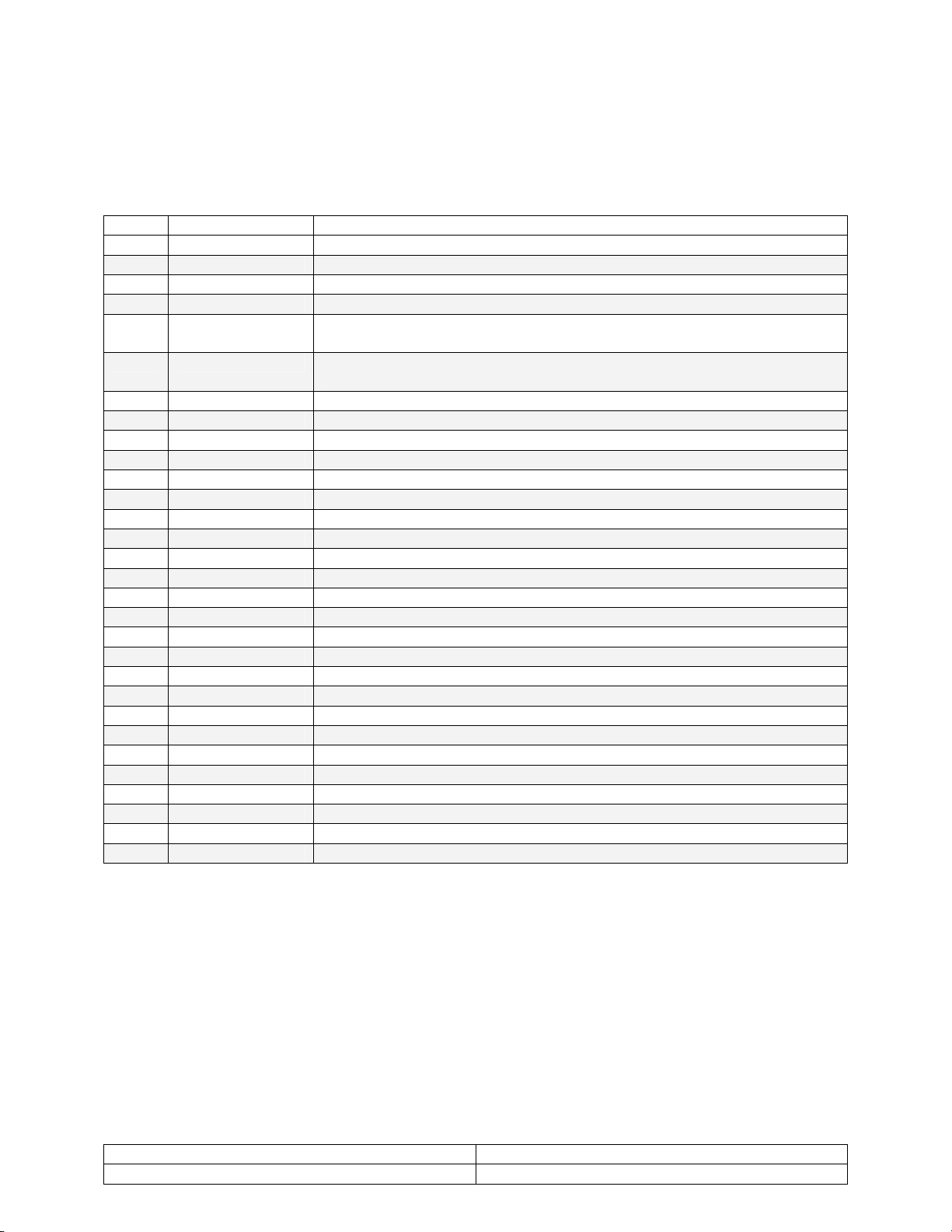

PIN# SIGNAL NAME DESCRIPTION

1 RxOIN0- Negative LVDS Differential Data Input (Odd Data)

2 RxOIN0+ Positive LVDS Differential Data Input (Odd Data)

3 RxOIN1- Negative LVDS Differential Data Input (Odd Data)

4 RxOIN1+ Positive LVDS Differential Data Input (Odd Data)

5 RxOIN2- Negative LVDS Differential Data Input (Odd Data, H-Sync, V-

Sync, DSPTMG)

6 RxOIN2+ Positive LVDS Differential Data Input (Odd Data, H-Sync, V-Sync,

DSPTMG)

7 VSS Power Ground

8 RxOCLKIN- Negative LVDS Differential Clock Input (Odd Data)

9 RxOCLKIN+ Positive LVDS Differential Clock Input (Odd Data)

10 RxOIN3- Negative LVDS Differential Data Input (Odd Data)

11 RxOIN+ Positive LVDS Differential Data Input (Odd Data)

12 RxEIN0- Negative LVDS Differential Data Input (Even Data)

13 RxEIN0+ Positive LVDS Differential Data Input (Even Data)

14 VSS Power Ground

15 RxEIN1- Negative LVDS Differential Data Input (Even Data)

16 RxEIN1+ Positive LVDS Differential Data Input (Even Data)

17 VSS Power Ground

18 RxEIN2- Negative LVDS Differential Data Input (Even Data)

19 RxEIN2+ Positive LVDS Differential Data Input (Even Data)

20 RxECLKIN- Negative LVDS Differential Clock Input (Even Data)

21 RxECLKIN+ Positive LVDS Differential Clock Input (Even Data)

22 RxEIN3- Negative LVDS Differential Data Input (Even Data)

23 RxEIN3+ Positive LVDS Differential Data Input (Even Data)

24 VSS Power Ground

25 VSS Power Ground

26 NC No Connection (for AUO test)

27 VSS Power Ground

28 VCC +5.0V Power Supply

29 VCC +5.0V Power Supply

30 VCC +5.0V Power Supply

Doc # 45M17 Issue Date: 11/09/05

Revision: B Page 6 of 12