EN - English - Instructions manual

3

Contents

ENGLISH

1 About this manual........................................................................................................ 5

1.1 Typographical conventions ................................................................................................................................ 5

2 Notes on copyright and information on trademarks ................................................ 5

3 Safety rules ................................................................................................................... 5

4 Identification ................................................................................................................ 6

4.1 Product description and type designation................................................................................................... 6

4.2 Product markings................................................................................................................................................... 7

5 Preparing the product for use..................................................................................... 7

5.1 Contents and unpacking..................................................................................................................................... 7

5.2 Safely disposing of packaging material ......................................................................................................... 8

6 Assembling and installing ........................................................................................... 8

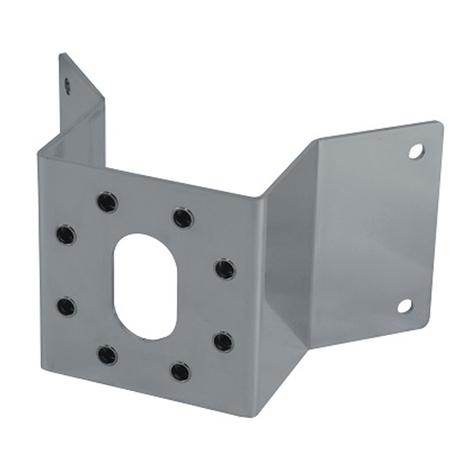

6.1 Installation ................................................................................................................................................................ 8

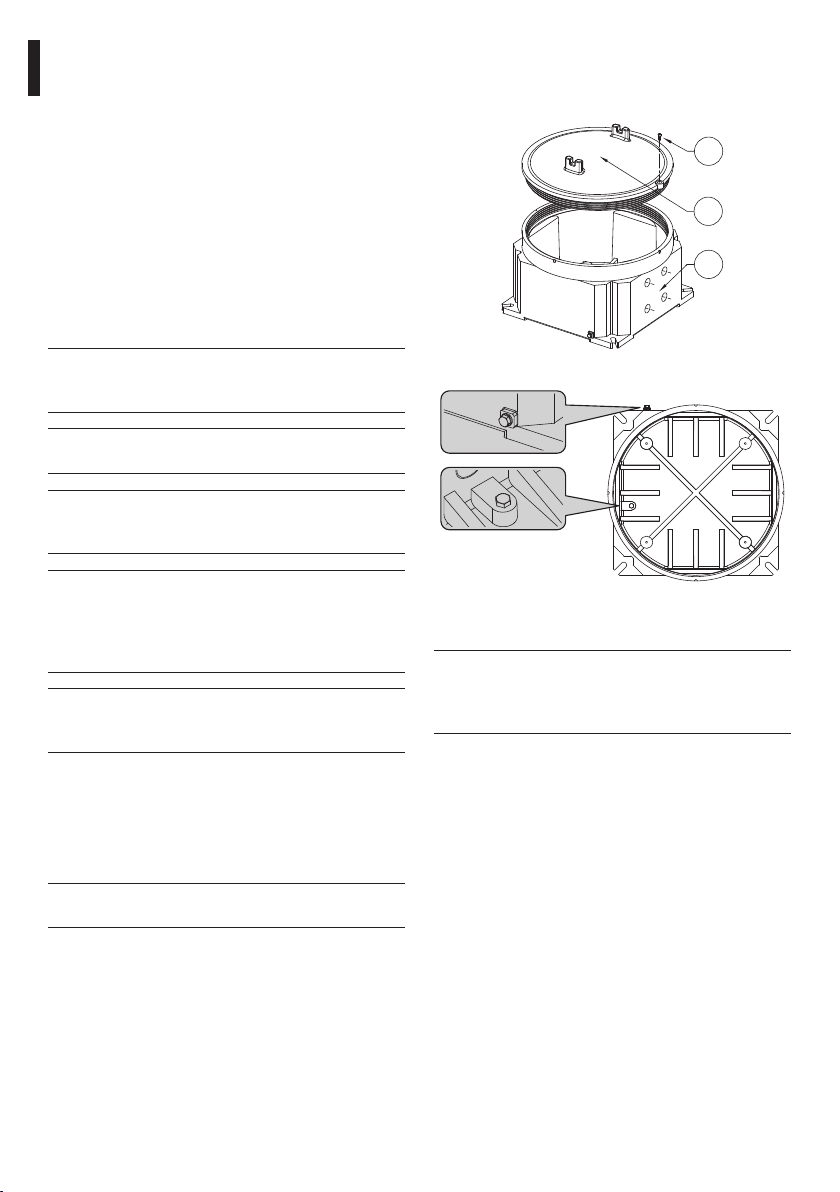

6.1.1 Receiver opening ................................................................................................................................................................... 8

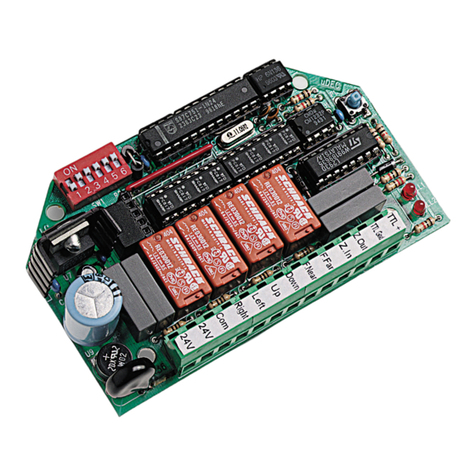

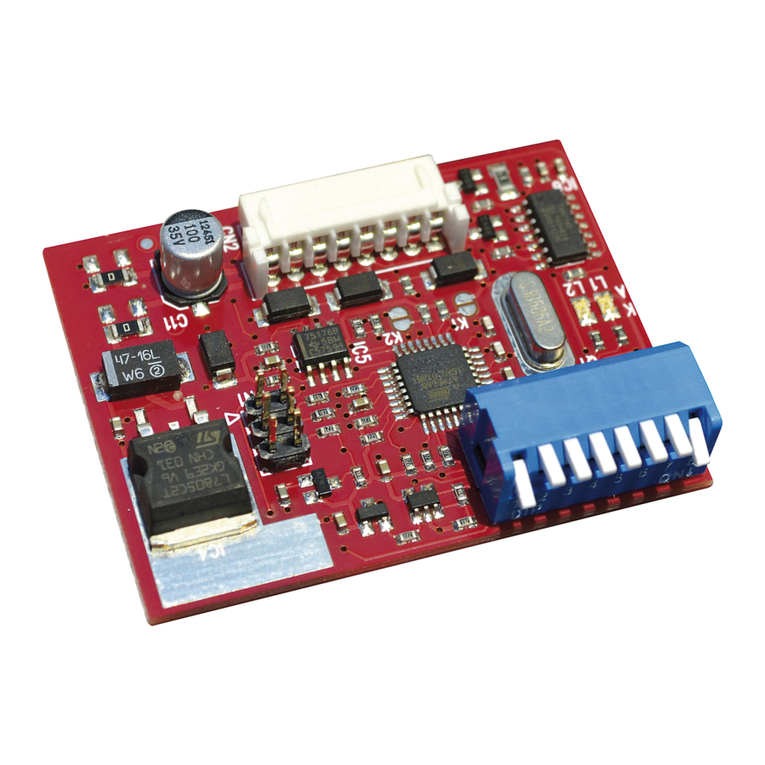

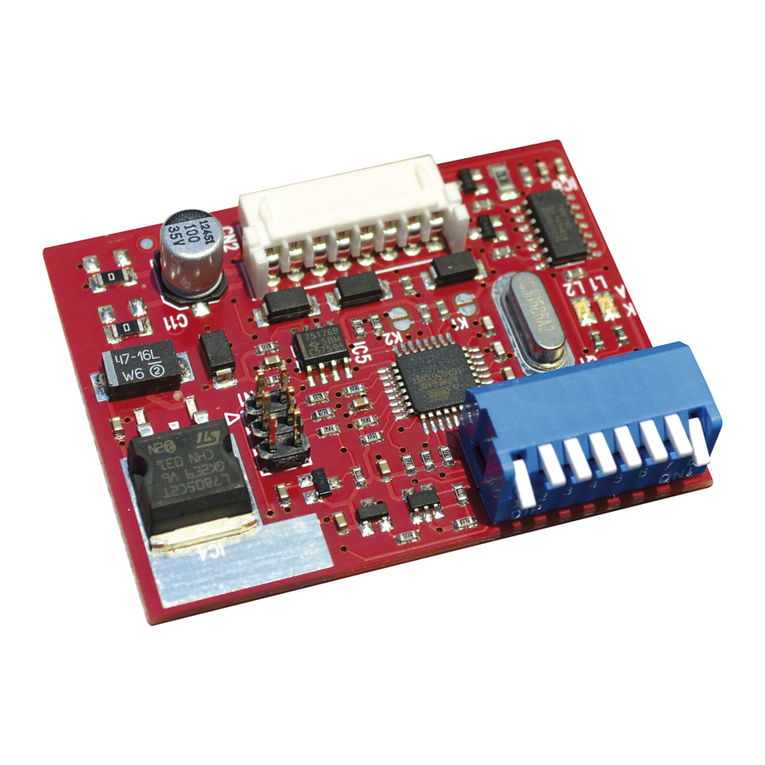

6.1.2 EXDTRX3 power supply........................................................................................................................................................ 8

6.1.3 EXDTRX324 power supply................................................................................................................................................... 9

6.1.4 Configuration of dip switches and jumpers...............................................................................................................10

6.2 Configuration.........................................................................................................................................................11

6.2.1 Receiver identification number setting .......................................................................................................................11

6.2.2 Receiving mode....................................................................................................................................................................11

6.2.3 Setting of RS485 line load.................................................................................................................................................11

6.2.4 Type of lenses used..............................................................................................................................................................11

6.2.5 Auxiliary contacts.................................................................................................................................................................11

6.2.6 Communication speed protocol setup........................................................................................................................12

6.2.7 AUX3 / AUX4 auxiliary devices setting .........................................................................................................................12

6.2.8 Connection with the control unit...................................................................................................................................12

6.2.9 Connection with the RS485 line .....................................................................................................................................12

6.2.10 Connecting more than one receiver in cascade (point-to-point connection) ............................................13

6.2.11 More than one receiver per line, connection with twisted pair cable (multipoint connection)...........13

6.2.12 Mixed configurations (point-to-point / multi-point) ............................................................................................14

6.2.13 Connection with the Current Loop line.....................................................................................................................15

6.2.14 Connection with the RS232 line...................................................................................................................................15

6.2.15 Adjusting the voltage of the optics controls...........................................................................................................15

6.2.16 Connecting the pan & tilt and optics cables............................................................................................................16

6.2.17 Setting the receiver for PRESET functions ................................................................................................................16

6.2.18 Testing the receiver...........................................................................................................................................................16

6.2.19 Use of the alarm contacts...............................................................................................................................................17

6.2.20 Operation mode of AUX4 ...............................................................................................................................................17

6.2.21 Local keys for P&T motor movement .........................................................................................................................17

6.2.22 PELCO D commands recognised by the receiver...................................................................................................17

6.2.22.1 Example of Patrol sequence programming...................................................................................................................................18

6.2.23 Switching on and switching off....................................................................................................................................18

6.2.24 Dip switch SW6 and SW4 configuration table.........................................................................................................18

7 Maintaining and cleaning.......................................................................................... 19