Viewpro Falcon F390 User manual

ViewproUAV Tech. Ltd www.viewprouav.com

1 of 27

页

Content

Content............................................................................................................................................... 2

Warning...............................................................................................................................................2

1. Unmanned Aerial System.............................................................................................................3

1.1 The UAV frame........................................................................................................................3

1.2 Electronic equipment..............................................................................................................3

2. Installation....................................................................................................................................5

2.1 Body installation......................................................................................................................5

2.2 Add fuel...................................................................................................................................6

3. Preparation Before Flight.............................................................................................................6

3.1 Aircraft center of gravity inspection........................................................................................6

3.2 Turn on the ground equipment...............................................................................................6

3.3 Remote control logic check.....................................................................................................7

3.4 Engine Inspection....................................................................................................................8

3.5 RTK Inspection.........................................................................................................................9

3.6 Installing the rotor propeller...................................................................................................9

3.7 Notes on route planning.......................................................................................................10

4. Description of Flight Controller..................................................................................................10

5. RTK Description..........................................................................................................................14

6. EFI Engine Description................................................................................................................16

7. UBEC Description........................................................................................................................19

8. Charger.......................................................................................................................................19

9. Remote Control Instruction........................................................................................................20

10. Aircraft Description..................................................................................................................21

10.1 Aircraft Specification...........................................................................................................21

10.2 Block Diagram of Aircraft Load Equipment.........................................................................22

10.3 Schematic diagram of aircraft equipment installation location..........................................22

10.4 Aircraft Equipment Wiring Instructions..............................................................................23

10.5 Flow Chart of Flight Operations..........................................................................................24

11. Routine maintenance of F390 UAV..........................................................................................25

ViewproUAV Tech. Ltd www.viewprouav.com

2 of 27

页

Warning

Safety Rules

Warning

This product is a special control item, and incorrect operation may cause damage to

items, personnel

Injury or even death, the user must bear the corresponding criminal responsibility. In

order to use this device better and ensure your safety, please read the relevant

manual carefully before use, or consult the manufacturer.

Precautions

ATC

*All aircraft take off and must apply for approval from the local air traffic control

department.*

Flight area

It is prohibited to fly over airports, railways, highways, inflammable and explosive

goods warehouses (factories), dangerous goods warehouses (factories), power

stations, high-voltage lines, military facilities, densely populated areas, and no-fly

areas designated by relevant departments. And strictly abide by the flight

management regulations of the user's location. If there are important protection

targets or unclear targets in the planned flight area, in addition to reporting to the air

traffic control, it is also necessary to report to the local garrison for approval.

Regional environment

The flight area must be surveyed to ensure that there are no obstacles in the flight

path. There will be strong shear winds between buildings and mountain streams, and

flying in them is prohibited. Don’t smoke or put fire around the gas.

Personnel status

All operators have been trained by civil aviation-approved training institutions,

obtained training completion certificates, and corresponding operating models; and

have mastered the operation methods and clear tasks. All operators must ensure

that they are in good condition, full of energy, and concentrated. It is forbidden to

operate the UAV in a state of illness, emotion or fatigue. All operators are prohibited

from drinking alcohol the night before and until the end of the flight.

ViewproUAV Tech. Ltd www.viewprouav.com

3 of 27

1. Unmanned Aerial System

1.1 The UAV frame

①Fuselage

②Carbon tubes

③ Left wing

④Left arm

⑤ Horizontal tail

⑥ Right arm

⑦Tail screws

⑧ Wing screws

⑨ Right wing

1.2 Electronic equipment

ViewproUAV Tech. Ltd www.viewprouav.com

4 of 27

1. Liquid level sensor: Used to monitor the amount of oil in the fuel.

2. Airspeed meter : It’s used to measure airspeed

3. Flight control: used to control the aircraft to perform various tasks

4. UBEC: Used to power servo, receiver and other equipment

5. Starter ESC: Used to control the starter motor

6. Oil pump: Fuel a pressure is supplied to the engine fuel injection system

7. Engine controller: Engine brain,control, adjustment, adapt and other function

8. RTK module: Dual RTK orientation and positioning

9. Fuel tank: storage of the fuel

10. Electronic speed controller: control motor speed

11. Servo: Controls the movement of the rudder surface of the aircraft

12. RTK antenna: RTK antenna used to pick up satellite signals

13. Pitot tube: From here air passes through the tachometer to the flight controller

14. Motor: An airplane motor that turns the propeller to provide upward lift

15. Propeller: Used to provide upward lift for airplane

16. Engine: The driving force of aircraft cruising

17. Some electronic devices: Landing lights, step-down modules, Hall sensors, relays, etc

ViewproUAV Tech. Ltd www.viewprouav.com

5 of 27

2. Installation

2.1 Body installation

1. 2→1,Complete the assembly of two carbon tubes and the body

2. 3→1→9,Ensure that two pairs of MR60 and two pairs of MR30 are firmly connected,

lock the buckles and confirm that the lock is correct, complete the wing and fuselage

assembly

3. 3→4,Ensure that two pairs of MR60 and two pairs of MR30 are firmly connected, so that

with ⑧ wing screws, check the wire harness without pulling extrusion, complete the

assembly of left wing and hanging rod

4. 9→6,Make sure that two pairs of MR60 and one pair of MR30 are firmly connected, use

⑧ wing screws, check the wire harness without pulling extrusion, complete the

assembly of right wing and hanging rod

5. 4→5→6,Ensure a pair of MR30 firmly connected, so that the use of ⑦ flat end screws,

complete the flat end assembly

6. F390 assembled

ViewproUAV Tech. Ltd www.viewprouav.com

6 of 27

2.2 Add fuel

1. Gasoline and oil are mixed in a 40:1 ratio.

2. There is a refueling/pumping port at the rear of the right side of the fuselage. Pull out the

tubing plug to carry out refueling and pumping operations, and ensure that the tubing plug

and tubing are connected reliably.

3. Check regularly for oil leakage or blockage.

4. Add the amount of mixed fuel to TPU tank according to the task requirements.

3. Preparation Before Flight

3.1 Aircraft center of gravity inspection

Put the center of gravity plate on the carbon tube, adjust the handle rope from the front to

the fourth slot, and pick up the handle rope. After the drone is off the ground, the attitude

of the drone is flush with the horizontal plane, which means the F390 drone has a suitable

center of gravity for flying. It is recommended to use 4 pieces of 6S 8000mA/h (25c) for the

multi-rotor power battery of the drone, and the hovering time is about 6 minutes. The

position of the power harness is flexible. According to different loads, the battery installation

position can be adjusted arbitrarily, and the center of gravity can be adjusted.

The handle rope is adjusted from front to back to the fourth slot

3.2 Turn on the ground equipment

3.2.1 Turn on the remote control

Turn on the remote control and check that the joystick trims are all in the neutral position.

Check whether the lever movement is normal. (The default remote control is Japanese hand

control, please contact the manufacturer if you need to change it)

ViewproUAV Tech. Ltd www.viewprouav.com

7 of 27

a: Under the engine power switch (stop switch), the engine is turned off, there is no action in

the middle, and the upper is turned on

b: Airplane mode switch (three-stage switch)

c: Navigation light switch (three-stage switch)

d: Engine starter switch (self-reset segment switch)

Additional levers and knobs can be customized

3.2.2 Connect the aircraft to the main power

When mains power is applied, the plug and battery are connected out of sequence. Do not

move the aircraft within 2 minutes after the system is initialized (other power sources are

temporarily unavailable)

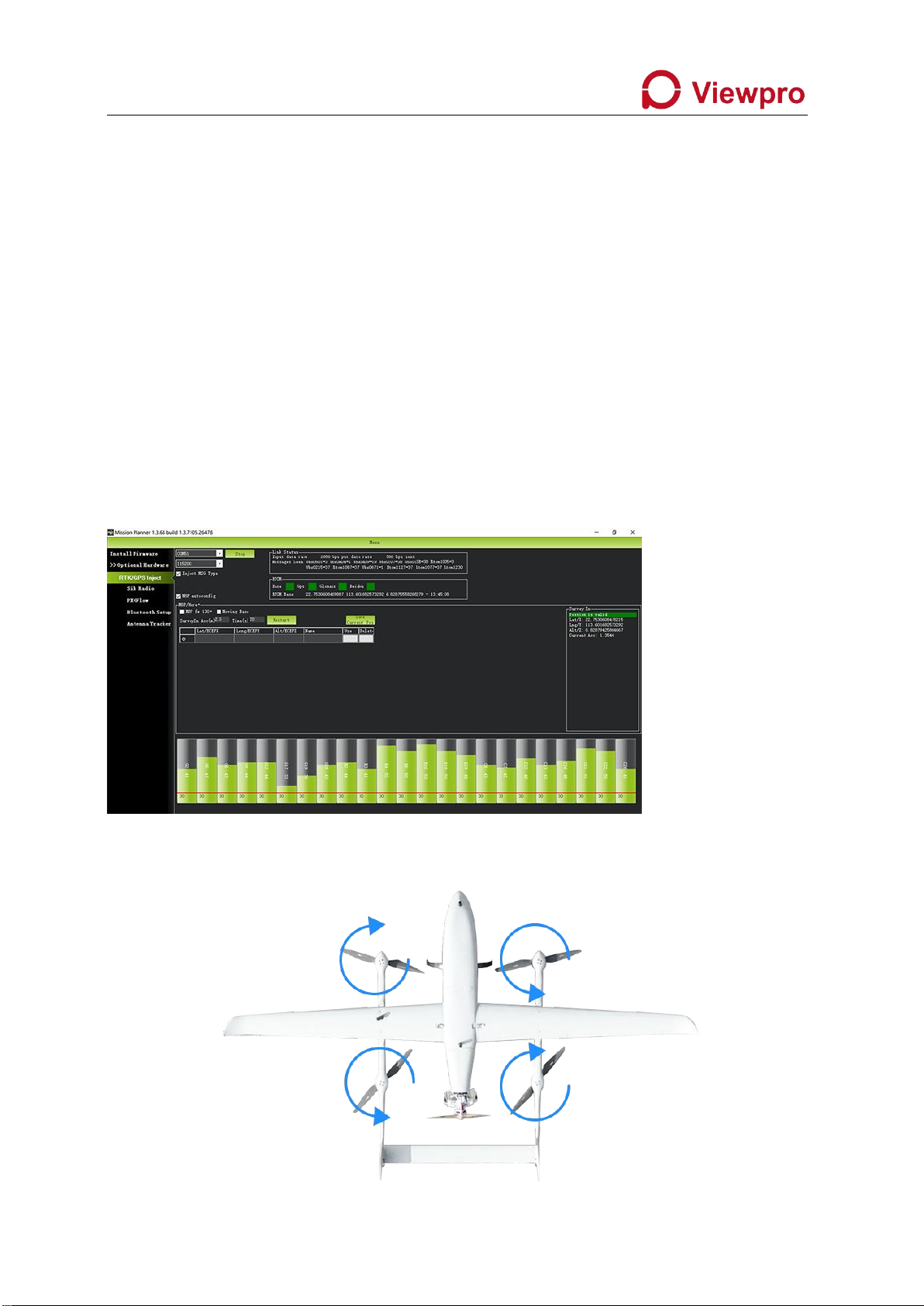

3.2.3 Ground station connection

Connect the remote control Bluetooth, the remote control Bluetooth name is

"SIYI-xxxxxxxxx". Open the mission planner software, select the serial port number mapped

by the remote controller's Bluetooth for the port, the baud rate is 57600, and connect.

3.3 Remote control logic check

3.3.1 Inspection of fixed-wing rudder surfaces

The ground station flight mode is set to Manual. Toggle the remote control to check whether

the corresponding rudder surface activity and logic are normal.

3.3.2 Check the throttle servo

ViewproUAV Tech. Ltd www.viewprouav.com

8 of 27

Set the flight mode of the ground station to Manual, the aircraft is unlocked, check whether

the throttle servo is moving normally, and whether the lever is good and stable.

3.4 Engine Inspection

3.4.1 Check the engine power switch

Turn on the engine battery, turn the engine power switch (stop switch) to on, and check that

the ECU light is on. Turn the engine power switch (turn off switch) to turn off the engine and

check that the ECU light is off.

3.4.2 Starting the engine

Connect the engine starter battery (12V30A/3S lipo battery), the starter self-checks for 3

seconds. Turn the engine power switch (stop switch) to ON. The ground station flight mode

is set to Manual, and the remote control unlocks the aircraft (make sure the rotor propeller

is not installed or removed before unlocking). Keep the throttle at the lowest level, start the

engine through the remote control lever, and release the start lever for 3 seconds (the

starter can be restarted after 20 seconds interval for 3 seconds). If the engine has not been

started 5 times. Please check wiring, switches and oil circuits.

3.4.3 Engine warm-up

Use the remote control throttle stick to control the engine and keep idling after 30-50

ViewproUAV Tech. Ltd www.viewprouav.com

9 of 27

seconds. Slowly push the throttle to the maximum and hold the maximum for 5-10 seconds.

Throttle idle for 10 seconds. Push the throttle to the engine speed of 3200-4000rpm, keep

the speed warm for 5-10 minutes (the temperature is below 10 degrees for more than 10-15

minutes). Idle the throttle for 10 seconds before turning it off. Engine warm-up completed

(engine warm-up can be placed before takeoff)

3.5 RTK Inspection

3.5.1 Dual RTK Orientation Check

Confirm that the ground station shows that at least one positioning status of GPS1 and GPS2

is RTK fixed, and the other positioning status is 3D positioning or RTK fixed. Turn the aircraft

to check that the heading is consistent with the actual heading.

3.5.2 RTK base station connection location check

After the base station is set up, use USB to connect the base station and the ground station

Initial settings - optional accessories - RTK/GPS inject - set serial port - click connect, all

green

3.6 Installing the rotor propeller

ViewproUAV Tech. Ltd www.viewprouav.com

10 of 27

3.7 Notes on route planning

1. The turning radius of the aircraft is 200 meters.

2. It takes 260 meters to switch from multi-rotor to fixed-wing

3. When return in fixed wing mode and switch to multirotor mode for landing, please turn

off the engineer on RC manually after you see the FC mode is QRTL mode on GCS. (The

engine can only be turned off when the aircraft switches to QRTL flight mode).

4. It takes 300 meters for fixed-wing return and multi-rotor

5. The readings of the fuel level gauge are for reference only and are not used as the actual

fuel level. Please calculate the flight time according to the flight mission. (Fuel consumption:

35KG take-off weight, using DLE60 EFI engine, with 23x12 propeller, the throttle opening is

about 25%, the cruising speed is about 4900r, the measured fuel consumption is 0.9L/h.

Reserve enough fuel for return landing)

6. The switching height is 50-70 meters.

4. Description of Flight Controller

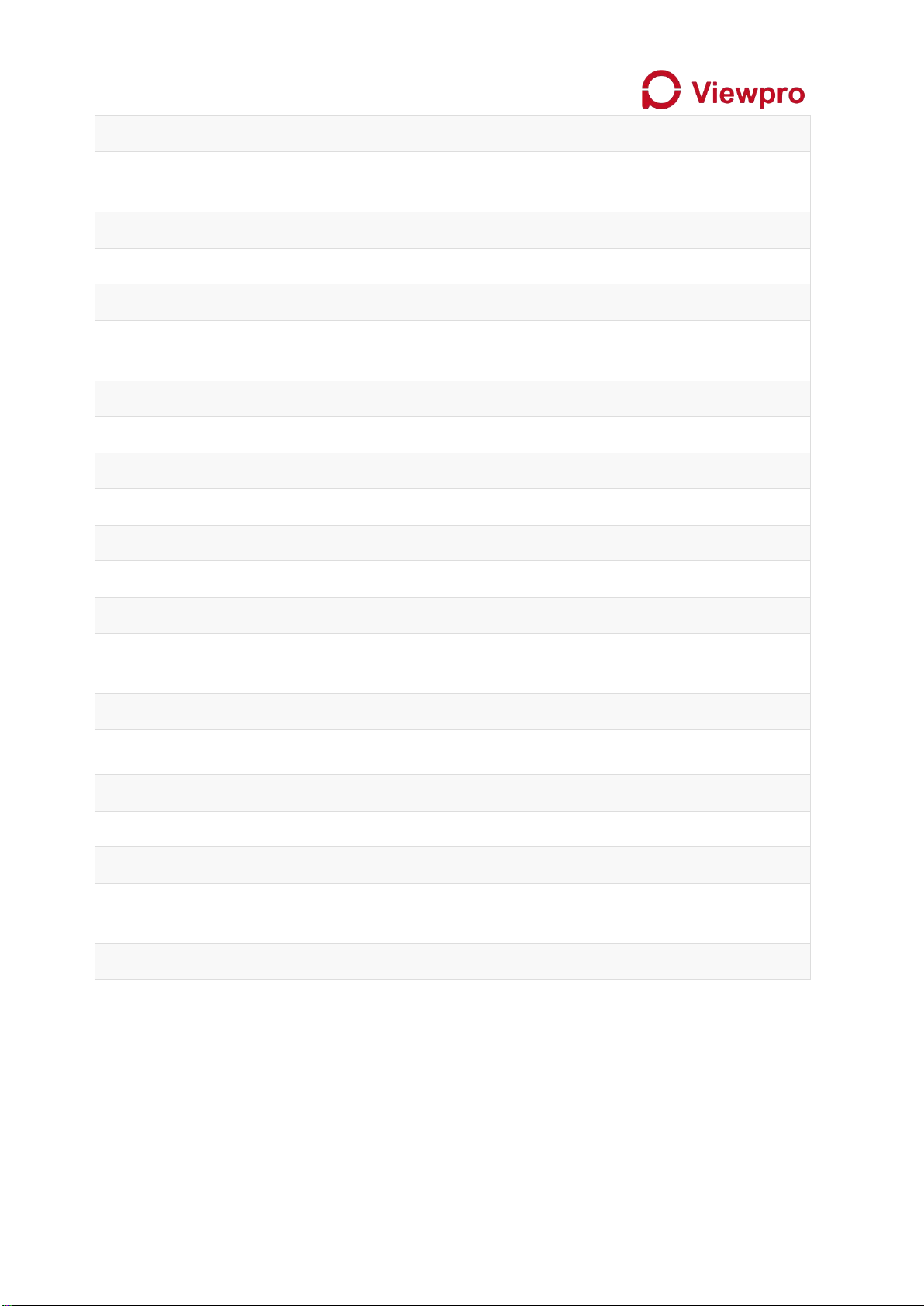

4.1 Specifications of flight controller

Processor

STM32H743

Sensor

Accelerometer

ADIS16470/ICM-20649/BMI088

Gyro

ADIS16470/ICM-20649/BMI088

Electronic compass

RM3100

barometer

MS5611*2

Interface

UART serial port

5

I2C

6 (4 separate i2c ports, two integrated in GPS/uart 4 ports)

ViewproUAV Tech. Ltd www.viewprouav.com

11 of 27

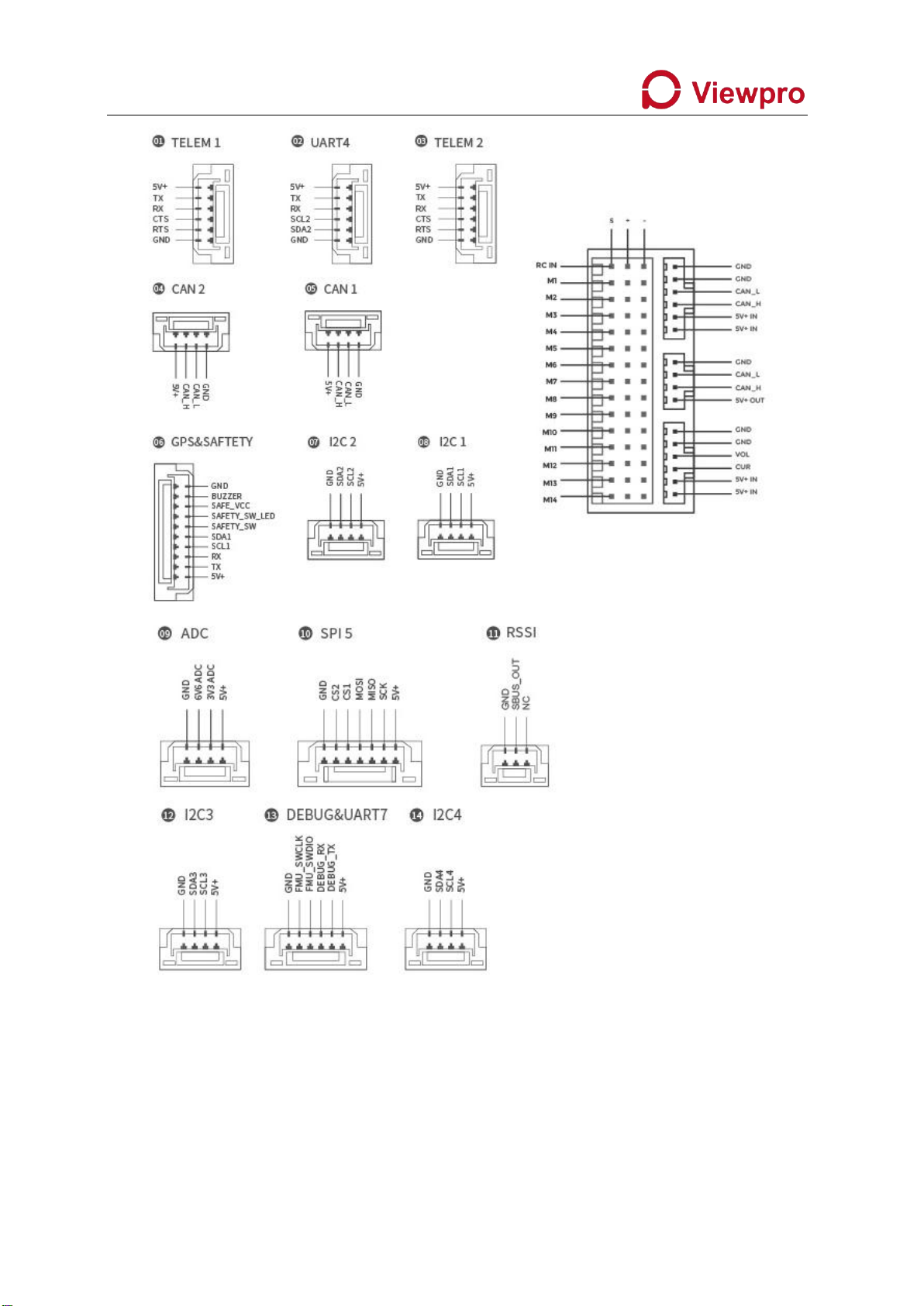

4.2 Definition of flight control interface

PWM output

14 (12 of them support dshot protocol)

Remote control signal

input protocol

PPM/SBUS/DSM

RC IN

1

RSSI input

PWM or 3.3V analog voltage

CAN standard bus

2

Power input

2 (Power A is the common ADC power detection interface;

Power C is the CAN galvanometer interface

Safety switch

1

GPS interface

2 (UART4 can be used as GPS2 interface)

Debug

1

JATG

1

ADC

1

USB interface

1

Supported Models

Ardupilot firmware

Fixed wing / 3-8 rotor / helicopter / VTOL vertical take-off and

landing / unmanned vehicle / unmanned boat, etc.

PX4 firmware

still in adaptation

Working environment and physical parameters

PM working voltage

4.5 ~ 5.5V

USB voltage

4.75 ~ 5.25V

Servo input

0 ~ 36v

Operating

temperature

-20 ~ 85°c

weight

101g

ViewproUAV Tech. Ltd www.viewprouav.com

12 of 27

ViewproUAV Tech. Ltd www.viewprouav.com

13 of 27

ViewproUAV Tech. Ltd www.viewprouav.com

14 of 27

5. RTK Description

5.1 RTK Specification

Satellite receiver type

184 channel Ubox F9P

Navigation Satellite

System

Beidou, Galileo, GLONASS, GPS / QZSS

Number of concurrent

navigation systems

4

Satellite band

GPS L1C/A L2C, GLONASS L1OF L2OF, GALILEO E1B/C E5b, BDS

B1I B2I, QZSS L1C/A L2C

Navigation refresh

rate

RTK up to 20 Hz

Positioning accuracy

RTK 0.01M+1ppm CEP

Convergence time

RTK<10S

Capture satellite

Cold start 24 s

Auxiliary start 2 s

Capture again for 2 s

Sensitivity

Tracking & Navigation: –167dBm

Cold start: –148dBm

Warm Start: –157dBm

Recapture: –160 dBm

Anti-interference

Active CW detection and cancellation

On-board filter

ViewproUAV Tech. Ltd www.viewprouav.com

15 of 27

Safety

Advanced Anti-Spoofing Algorithms

Interface

Serial

2 UARTs

USB

1

Antenna

Multi-satellite multi-frequency antenna

Time pulse

Configurable from 0.25hz to 10mhz

Data protocol

NMEA, UBX binary, RTCM 3.x

Other Information

Input voltage

4.5V to 6V

Operating

temperature

–40 °C to +85 °C

Size

31.5*48*12MM

weight

21g

5.2 RTK LED Status Light and Interface Definition

ViewproUAV Tech. Ltd www.viewprouav.com

16 of 27

6. EFI Engine Description

6.1 Engine Specifications

Performance :

7HP/8500rpm

Idle speed:

1400 rmp/min

Pull:

15.2kg/100 meters above sea level

Pull:

13.5kg/1800 meters above sea level

Applicable propeller

specifications:

22x10; 23x8; 23x10; 24x8

Applicable spark plug

models:

NGK CM6

Displacement:

60cc

Bore x Stroke:

36mm×30mm

Compression ratio:

7.6:1

Lubrication ratio:

30:1

Host weight:

1560g

Exhaust pipe weight:

200g

ViewproUAV Tech. Ltd www.viewprouav.com

17 of 27

Igniter Weight:

190g

Igniter Voltage:

4.8V-8.4V

6.2 Definition of engine interface

ViewproUAV Tech. Ltd www.viewprouav.com

18 of 27

ViewproUAV Tech. Ltd www.viewprouav.com

19 of 27

6.3 Maintenance timing

Item

Before Each

Takeoff

Every 25hrs

Every 50hrs

Every 100hrs

Pre-mix the

fuels

√

Sparking Plug

Checking

√

Sparking Plug

Replace

√

Air Filter

Replace

√

Fuel Filter

Replace

√

7. UBEC Description

UBEC interface definition

8. Charger

Specifications of the charger

Input voltage

100-240V

Output Power

1080W (540W x 2)

Discharge power

100W (50W x 2)

Charge current range

1.0-20.0A x 2

Maximum balance current

1.2A

Rechargeable battery type

LiPo/LiHV

Table of contents

Other Viewpro Drone manuals