Parker Hannifin Corporation

Filtration and Separation Division

Oxford, MI

OPERATION

Air coalescing is a continuous, balanced, steady-state process occuring at

or below rated flow, which depends on two factors for high performance:

(1) The bowl must be kept free of waste liquid build-up and (2) The element

must be replaced when the differential pressure reaches 6-10 psid, 12 psid

maximum. Differential pressure can be sensed at the inlet and outlet

ports by two gauges, or by observing system characteristics.

Bowl draining is accomplished by slowly opening the manual drain valves,

at least once every 8 hours depending on the liquid load. Finite's new High

Pressure Drain Kits are useful tools that can be utilized in order to safely

drain condensate from a high-pressure air / gas system. See Finite Bulletin

NP024 for more details.

A Finite coalescer, under normal system conditions, will operate for 6 to

12 months before reaching its maximum differential pressure. With shorter

coalescing element life a "PWC" series Particulate or"WS" Water Separa-

tor element should be employed ahead of the coalescer to increase its life.

A precoalescer (Grade 10) can also be used to extend the life of the high

efficiency coalescer (Grade 4).

Finite coalescers are designed for nominal operation with 10-20 wt.oil. Any

viscosity increase over that of 20 wt. oil must be offset by a proportionate

oversizing of the filter element. Consult your Finite representative.

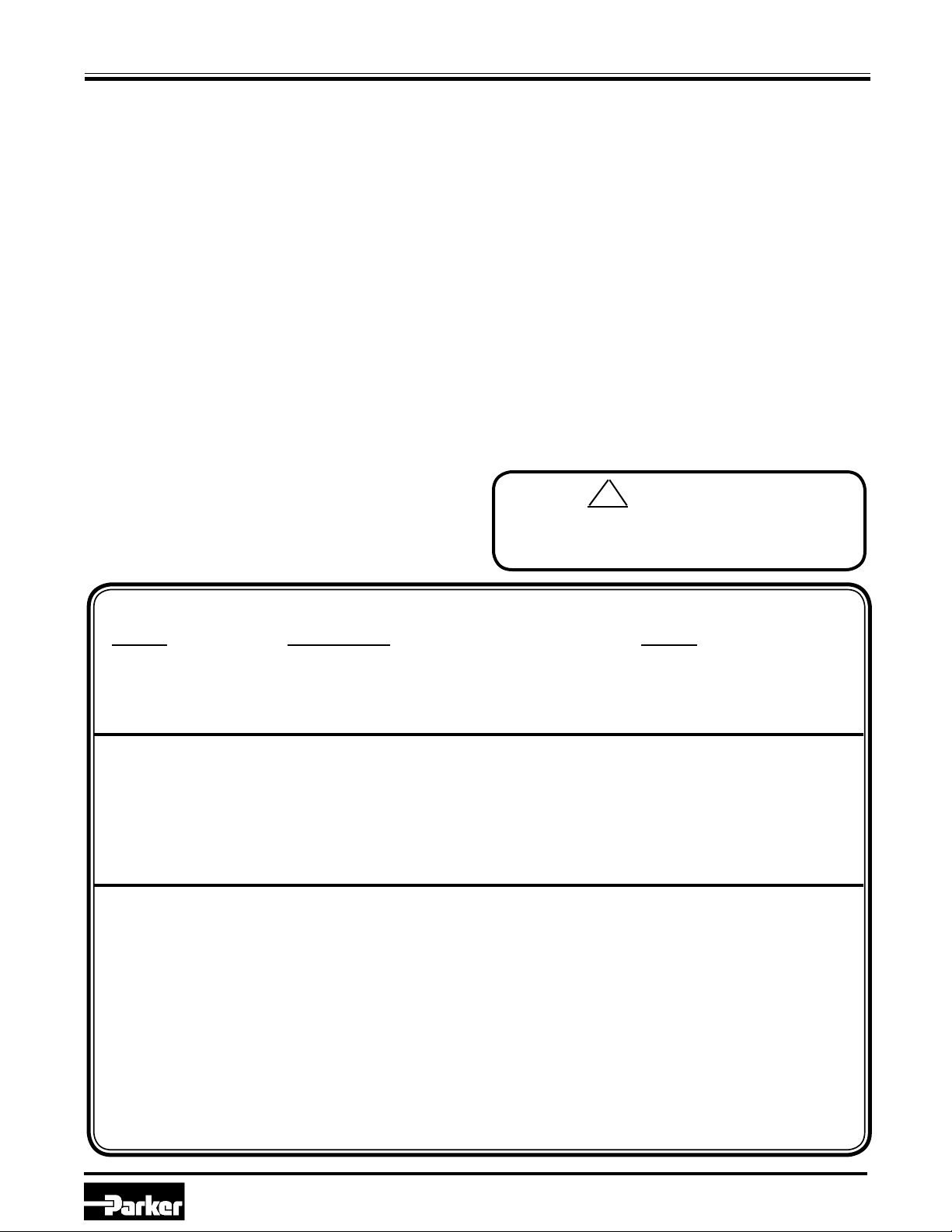

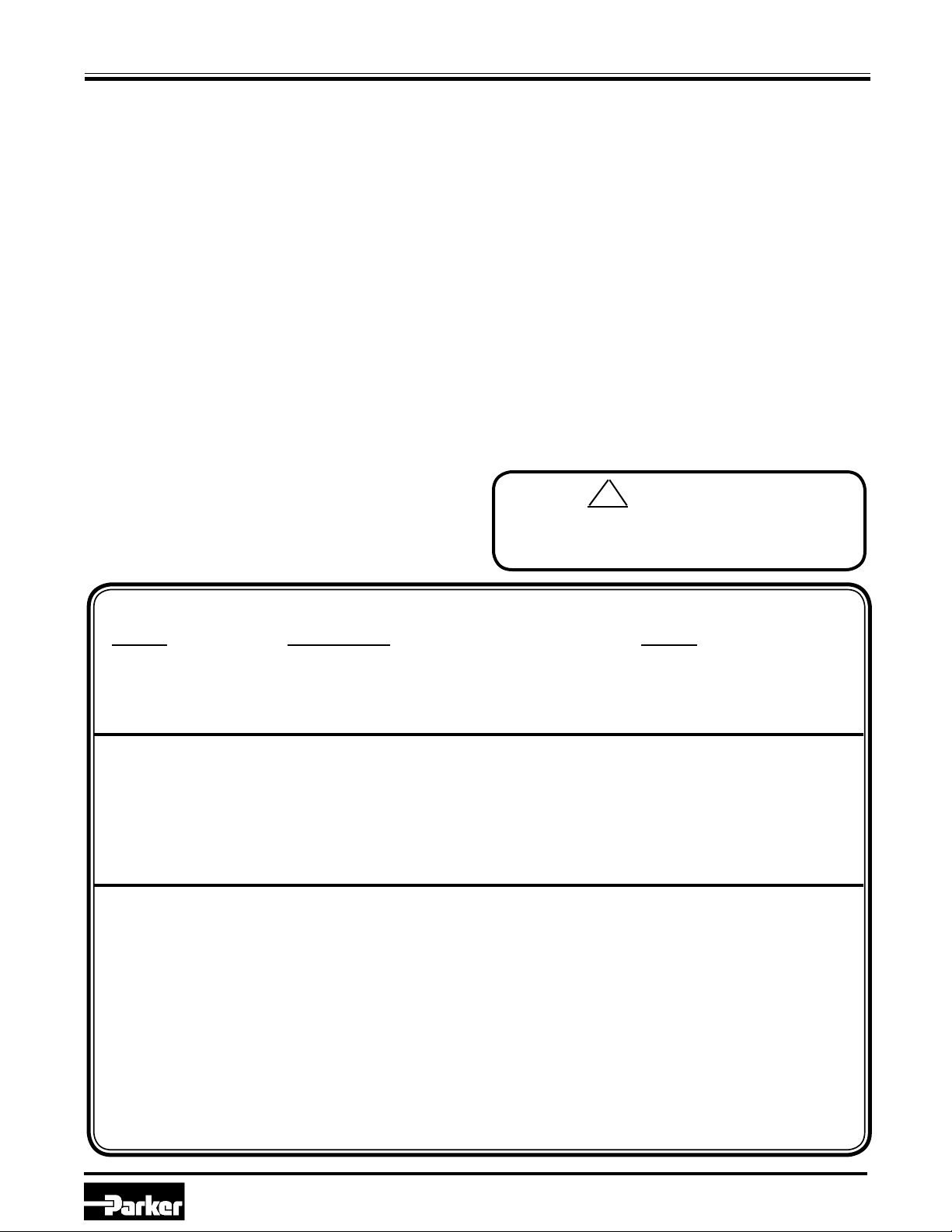

PROBLEM PROBABLE CAUSE SOLUTION

Too High Initial Air flow excessive for housing size. Install larger filter.

Pressure Drop Filter media grade too fine. Install coarser element.

Too much oil/water from compressor. Pre-coalesce with grade 10 - oversize

housing.

Premature Clogging Lubricant improperly selected for compressor, Change oil, consult with lubricant

(Air Flow Drops Off) causing varnish or carbonizing of lubricant. supplier.

Excessive inlet particulate contamination. Prefilter with Particulate Filter.

Excessive lubricants present on element caused Prefilter with Grade 10 or 100WS and

by either high lubricant viscosity or very high oversize coalescer to compensate.

inlet aerosol level.

Oil/water emulsion forming on element. Remove water by drip leg, aftercooler.

Install mechanical separator upstream.

Oil Present Down- Bowl not properly drained of waste liquids. Drain regularly, use auto drain.

stream of Filter

Element not sealing. Replace element.

Filter piped backwards. See "INSTALLATION"; Re-pipe.

Filter being by-passed by valving. Close valve.

Contaminated air entering system from second Change pipe or relocate filter.

source downstream.

Oil vapors condensing downstream. Install an adsorber.

Excessive inlet oil level. Precoalesce with Grade 10 and

possibly oversize.

Element damaged, chemically attacked or not Change and consult distributor

installed in housing. or factory for other than neutral pH.

Oil present in pre-contaminated Clean piping.

downstream piping.

Maintenance Bulletin - J-Series

(J2SD, J2SL, J4SF, J4NF, J6SH, J6NH) MB-JSeries 04/05

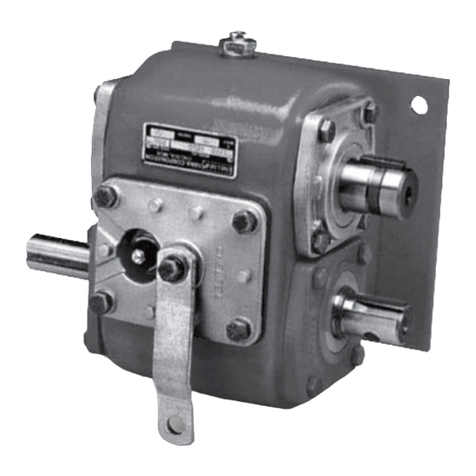

INSTALLATION

Finite Coalescer "CWC", Particulate "PWC", Adsorber "AWC", Water Separator

"WS" filters and the desiccant cartridges "10JW" should be installed in a level

pipeline, mounted vertically, the bowl downward with one element length clear-

ance for element removal. The filter should be installed at the highest pressure

available, as near as possible to the equipment to be protected. It should also have

a drip leg immediately upstream. All filters should be visible and easily accessible

for periodic draining and maintenance.

The filters should be piped in accordance with the instruction tags and flow arrows.

Should these tags become unreadable, install the coalescer and water separator so

that flow passes through the filter tube from inside-to-outside. Plumb particulate

and adsorber filters so that flow passes through the filter from outside-to-inside.

The filter locations relative to other equipment should be as follows (unless specific

instructions are given to the contrary): (1 ) The COALESCER is placed before

the dryer.(2) The PARTICULATE or WATER SEPARATOR goes ahead of the

COALESCER when prefiltration is required. (3) The PARTICULATE is installed

downstream of desiccant dryers to prevent desiccant migration.(4) The ADSORBER

and DESICCANT CARTRIDGE are always preceded by a COALESCER.

MAINTENANCE

When Coalescer or Interceptor differential pressure reaches clogged condition

(6-10 PSID) replace element immediately. DO NOT ATTEMPT TO CLEAN

FILTER TUBE. System contamination can result. DO NOT ATTEMPT TO

RESEAT A FILTER TUBE. New serrated indentations can be formed causing

leakage. DO NOT BY-PASS THE COALESCER unless the by-pass line is also

filtered. DANGER

Filter housings must be depressurized before

performing any maintenance activities, and depressurization

verified by a pressure gauge known to be in working order.

!

TROUBLESHOOTING CHART