1010

Product Scope of supply

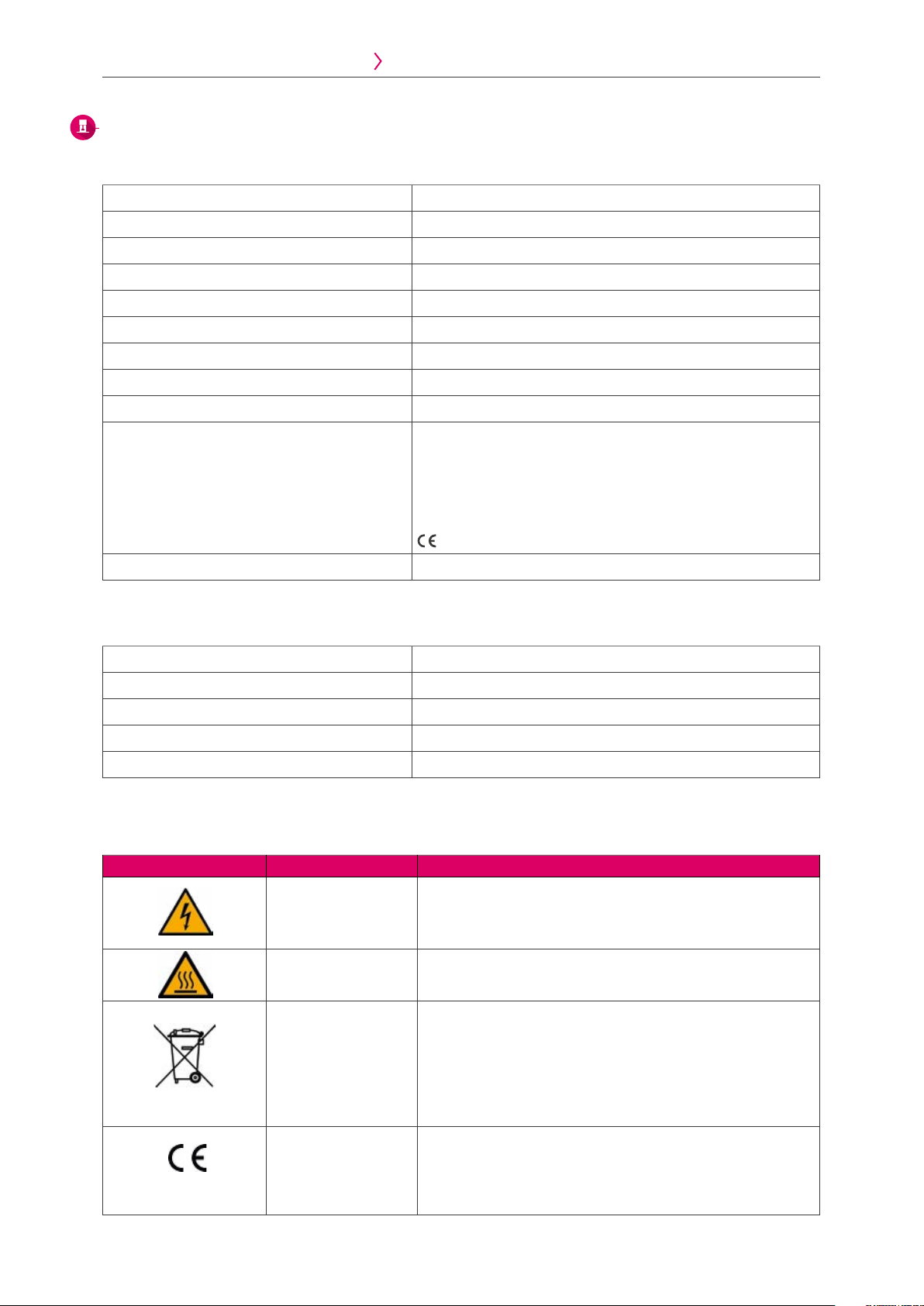

Hazardous voltage This pictogram warns the user about hazardous voltage. Before opening

the instrument, always disconnect it from the mains current by unplugging

the power plug.

Hot surface This pictogram warns the user about hot surfaces Burns are possible.

Separate disposal This unit and all accessories labeled with this symbol are subject to Directive

2002/96/EC (WEEE) and the applicable national regulations and may not be

disposed of as unsorted municipal waste in the European Union (EU).

Old units can be returned to VITA Zahnfabrik.

CE marking VITA SMART.FIRE complies with the applicable regulations of the European

Union (EU). The declaration of conformity can be requested from VITA

(Regulatory Affairs Department) at: www.vita-zahnfabrik.com

3. Scope of supply / system solutions 4. Technical data / information 5. Additional information

4. Technical data / information

4.1 Technical data for firing unit

4.2 Technical data for control unit

Dimensions (Ø / depth / height) 230 mm / 300 mm / 340 mm (closed)

Net weight 12 kg

Firing chamber internal dimensions (Ø / height) 80 mm / 43 mm

Firing chamber temperature Max. 1050°C

Electrical connection Specified on identification plate, tolerance ±10 %

Power consumption Max. 950 W (230 V), max. 1100 W (100 V, 110 V)

Temperature range for operation: 10°C to 35°C

Humidity for operation Max. 80% RH

Operating altitude Max. 3,800 m above sea level

Classifications EN 61010-10:2010

EN 61010-2-010:2014

UL 61010-1:2012

UL 61010-2-010:2015

CAN/CSA-C22.2 NO. 61010-2-010:2015

Application area Approved for indoor operation only

Dimensions (width / depth / height) 260 mm / 150 mm / 200 mm

Net weight 1.6 kg

Temperature for operation 10°C to 35°C

Humidity for operation Max. 80 % RH

Application area Approved for indoor operation only

4.3 Symbols