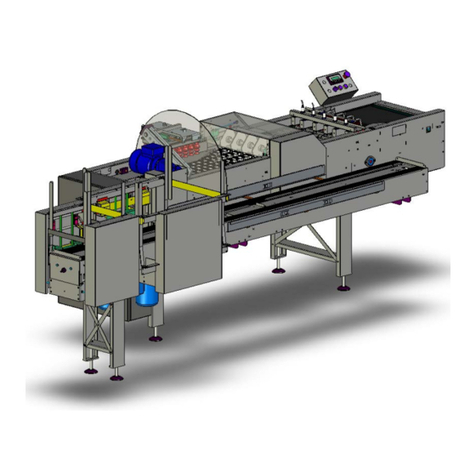

Vitronics Soltec mySelective 6748 User manual

Installation Guide

mySelective 6748

Version 48.1.0.006

VITRONICS SOLTEC BV

Visit address Innovatiepark 12 - 4906 AA Oosterhout - the Netherlands

Mail address P.O. Box 143 - 4900 AC Oosterhout - the Netherlands

Telephone +31-162-483000

Fax +31-162-483269

www.vitronics-soltec.com

ii

Rights

COPYRIGHT 2010 VITRONICS SOLTEC BV

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any

means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Vitronics Soltec BV.

This publication remains the property of Vitronics Soltec BV and may not be passed, loaned or given to any third party.

Vitronics Soltec BV reserves the right to make changes in design and specifications without notice.

EUROPE

VITRONICS SOLTEC BV VITRONICS SOLTEC GmbH

Innovatiepark 12 Udo-Lermann Str.10

4906 AA Oosterhout 97828 Marktheidenfeld

the Netherlands Germany

Tel. +31-162-483000 Tel. +49-9391-98820

Fax +31-162-483269 Fax +49-9391-988228

AMERICAS

VITRONICS SOLTEC Inc.

2 Marin Way

Stratham, New Hamphire 03885

USA

Tel. +1-603-772-7778

Fax +1-603-772-7776

ASIA PACIFIC

VITRONICS SOLTEC SHANGHAI VITRONICS SOLTEC (SUZHOU) Co. Ltd

Sales Office Manufacturing Plant

858 Zhujiang Lu 858 Zhujiang Lu

Building 2 Building 2

Suzhou New District, China 215129 Suzhou New District, China 215129

Tel. +86-21-5033-7855 Tel. +86-512-6841-3378

Fax +86-21-6360-9449 Fax +86-512-6841-3161

VITRONICS SOLTEC PTE LTD. VITRONICS SOLTEC KOREA

132 Joo Seng Road A-1001, Poonglim Iwant Bldg.

#03-01 Uniplas Building 255-1 Seohyun Dong,

Singapore 368358 Bundang Gu, Seongnam 463-862, Korea

Tel. +65-6484-3010 Tel. +82-31-783-7020

Fax +65-6484-1910 Fax +82-31-783-7021

VITRONICS SOLTEC MALAYSIA

8-2-5 Sunny Point Complex

Jalan Sultan Azlan Shah, Batu Uban,

11700 Penang, Malaysia

Tel. +60-4-658-4227

Fax +60-4-655-4227

Installation Guide mySelective 6748 iii

Preface

During the composition of this manual much attention is given to avoid errors

and mistakes. Also we aimed to give the contents a clear structure.

If during the use of this manual errors or incomplete descriptions are found, or

the reader considers that improvements are necessary to overcome any in-

accuracies, please inform us. We appreciate any comments which will help us to

improve this documentation.

For corrections or clarifications please contact:

1. By mail:

VITRONICS SOLTEC BV

HEAD OFFICE

TECHNICAL PUBLICATIONS

P.O. BOX 143

4900 AC OOSTERHOUT

THE NETHERLANDS

TEL NR. (31) - 162483000

FAX.NR. (31) - 162483285

OR

2. By e-mail:

techpub.nl@vsww.com

iv

Installation Guide mySelective.com v

Ta b l e o f C o n t e n t s

Preface iii

Table of Contents v

1 Installation 1-1

1.1 General . . . . . . . . . . . . . . . . . . . 1-1

1.2 Transport . . . . . . . . . . . . . . . . . . 1-1

1.2.1 Symbols used . . . . . . . . . . . . . . . 1-1

1.2.2 Unpacking . . . . . . . . . . . . . . . . 1-2

1.2.3 Lifting with forklift . . . . . . . . . . . . . 1-3

1.2.4 Centre of Gravity . . . . . . . . . . . . . . 1-3

1.3 Putting in position . . . . . . . . . . . . . . . 1-4

1.3.1 MultiFlux and Robot . . . . . . . . . . . . . 1-4

1.4 Connections . . . . . . . . . . . . . . . . . 1-6

1.4.1 General . . . . . . . . . . . . . . . . . 1-6

1.4.2 Electrical connection . . . . . . . . . . . . . 1-6

1.4.3 Nitrogen connection . . . . . . . . . . . . . 1-6

1.4.4 Exhaust system . . . . . . . . . . . . . . 1-6

1.4.5 Personal computer . . . . . . . . . . . . . 1-6

1.5 Mechanical installation . . . . . . . . . . . . . . 1-7

1.5.1 Measuring conditions . . . . . . . . . . . . . 1-7

1.5.2 Measuring methods . . . . . . . . . . . . . 1-7

1.5.3 Measuring tools . . . . . . . . . . . . . . 1-7

1.6 Mechanical settings . . . . . . . . . . . . . . . 1-8

1.6.1 Frame & Robot . . . . . . . . . . . . . . 1-8

1.6.2 Filling the solderpot . . . . . . . . . . . . . 1-10

1.7 Installation sheet . . . . . . . . . . . . . . . . 1-10

Index vii

vi

ICON DESCRIPTION ICON DESCRIPTION

Only Qualified personnel is allowed to work on the

equipment.

Never eat, drink or smoke while working on the

machine.

Wash thoroughly before eating, drinking or smoking.

High voltages are present on various parts of the sys-

tem.

Before working on the electrical circuit, turn main

power off and block the mainswitch with a padlock.

Always wear heat resistant gloves and protective

clothing when working on the machine.

If possible allow the machine to cool down before

starting working on the machine.

When burned, immerse in cold water immediately.

When the burn is severe, consult a physician as soon

as possible.

Always wear heat resistant gloves and protective

clothing when working on the machine.

If possible allow the machine to cool down before

starting working on the machine

When burned, immerse in cold water immediately.

When the burn is severe, consult a physician as soon

as possible.

No smoking or open fire near the machine.

Be sure a fire-extinguisher is in the surroundings of

the machine.

No smoking or open fire near the machine.

Be sure a fire-extinguisher is in the surroundings of

the machine.

All moving parts of the system, including pulleys,

belts, chains, coolingfans, sprocketwheels, vacuum-

doors and cylinders presents a potential danger.

Be careful with covers and doors. Always pay atten-

tion to opening and closing.

The vapours in the board preparation module are

chemical. When the board is heated, a noxious

vapour will be liberated. This vapour must be

extracted. Also the dust on the surface of the solder-

pot is dangerous when inhaled.

Avoid inhaling this vapours / dust by using mouth

protection.

When working on the machine, always protect your

eyes with safety glasses.

Nitrogen

N2

Follow the safety precautions and procedures

described in the Material Safety Data Sheet of

the Nitrogen supplier.

UPS

Uninterruptible

Power Source

When mainswitch is switched OFF for a longer

period, switch the UPS to OFF.

Signal light RED

- E-stop Active

Signal light GREEN

- Steady = Machine Run,

- Flashing slow = Machine not at setpoint, machine

stop

Signal light ORANGE

- Steady = Overload (outfeed full), Machine will

block,

- Flashing slow = Alarm

- Flashing fast = Critical alarm. Machine will block

LASER RADIATION

Do not stare into beam.

Class 2 Laser product.

Only applicable for Soldering machines

equipped with laser measurement systems.

If these rules are not observed it can cause personal injury and/or damage to the machine

SAFETY RULES

GENERAL INFORMATION

.

Unpacking / Installing mySelective.com CHAPTER 1 1

Installation 1

1.1 GENERAL

Installing only by trained Vitronics Soltec / Agent personnel.

At the end of this chapter an installation sheet is located.

1.2 TRANSPORT

1.2.1 SYMBOLS USED

FIGURE 1.1 SYMBOLS ON PACKAGING

1. Position pallet/box for transport

2. Breakable

3. Keep dry

4. Lift here (labels are placed on

position where forklift should lift)

12 4

3

VERSION April 2008

INSTALLATION

2CHAPTER 1

1.2.2 UNPACKING

The Vitronics Soltec mySelective.com is standard packed on a wooden floor.

1.2.2.1 PACKED IN CRATE

When necessary, the machine is packed in crates (e.g. when shipped).

If packed in crates the following procedure should be followed.

FIGURE 1.2 CRATE

Uncrate order:

1. Take off top cover A.

2. Remove side panels B.

3. Remove front and backcover C.

Use the above figure order A,B,C to uncrate. Other order can result in damaging the machine or

personal injury.

1.2.2.2 PACKED ON AWOODEN FLOOR

Unpacking order:

1. Remove PE-foil.

2. Remove lash cord and take off spare parts.

3. Remove lash cord and foam from machine.

4. Remove machine from wooden floor according to next paragraph.

CB

A

1.2 - TRANSPORT

Unpacking / Installing mySelective.com CHAPTER 1 3

1.2.3 LIFTING WITH FORKLIFT

When the transporting straps are removed, the mySelective.com can be placed on the place the

customer has provided.

To lift and transport the mySelective.com use the positions as shown in the installation sheet at

the end of this document.

FIGURE 1.3 LIFT POSITIONS

1.2.4 CENTRE OF GRAVITY

Depending on the machine configuration, and empty or filled solderpot(s), the Centre of Gravity

will vary. Below 4 examples. Note: these examples are illustrative!

FIGURE 1.4 CENTRE OF GRAVITY

INSTALLATION

4CHAPTER 1

1.3 PUTTING IN POSITION

After the machine is placed on its location, the next steps should be followed.

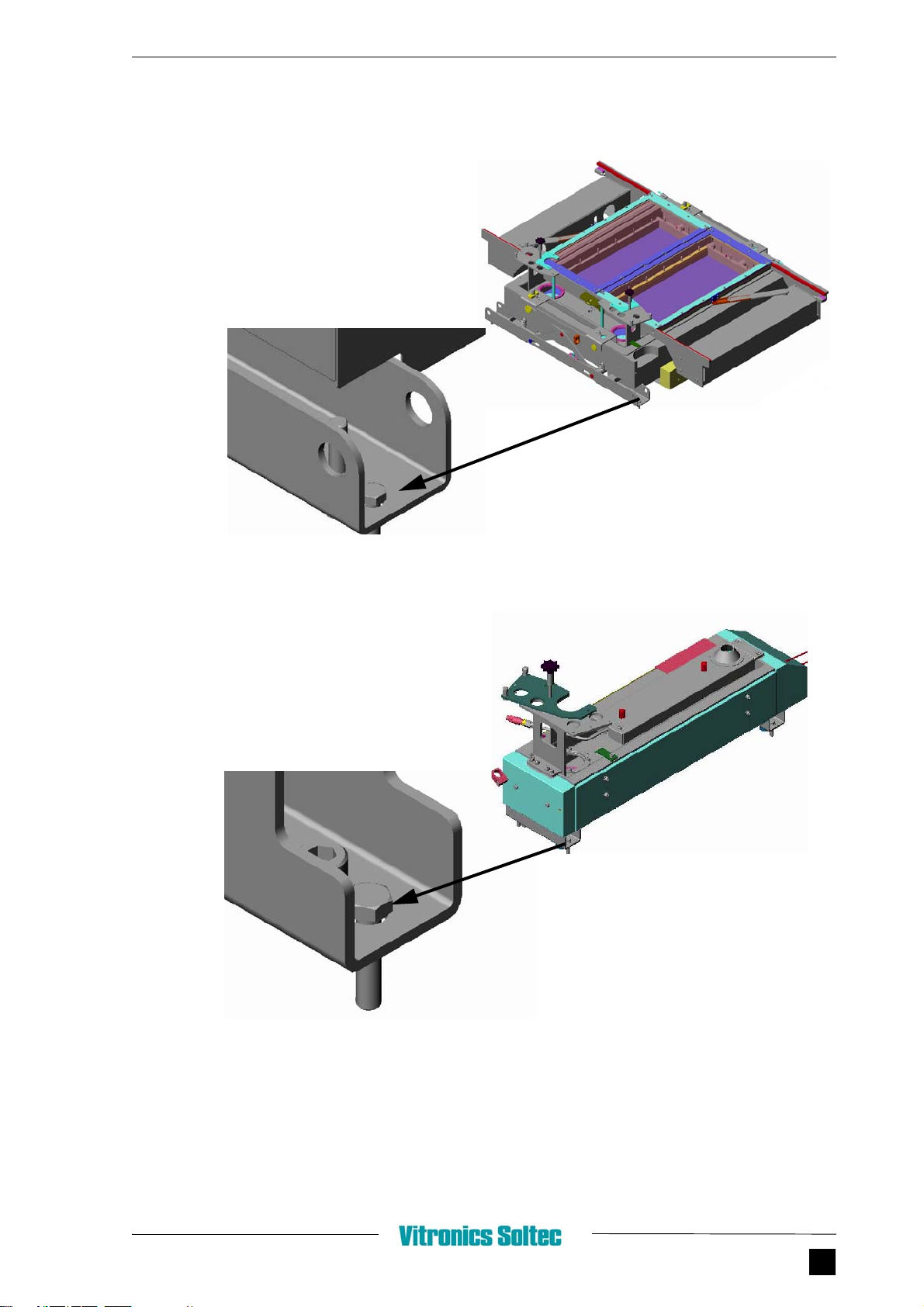

1.3.1 MULTIFLUX AND ROBOT

FIGURE 1.5 REMOVAL OF TRANSPORT PROTECTIONS

MultiFlux

1. Remove red Transport strips at MultiFlux unit

Robot

1. Remove red Transportstrips at Robot unit.

2. After removing the transport strips, use

mounting materials in plastic bag, to replace the

bolts used for transport strips.

1.3 - PUTTING IN POSITION

Unpacking / Installing mySelective.com CHAPTER 1 5

FIGURE 1.6 MULTIWAVE AND SELECTWAVE

REMOVE THE M8 BOLTS (4X) ON THE

MULTIWAVE

REMOVE THE M8 BOLTS (4X) ON THE

SELECTWAVE

INSTALLATION

6CHAPTER 1

1.4 CONNECTIONS

1.4.1 GENERAL

See for connection specifications the “install sheet” at the end of this chapter.

1.4.2 ELECTRICAL CONNECTION

Only qualified electricians should work on the electrical circuits of the machine.

1. Connect the mains leads in accordance with the diagrams.

Check the Current rotation of the phases. The current rotation of the phases L1, L2, L3 must be

clockwise.

2. Block the mainswitch in the “OFF” position with a padlock to prevent dangerous situations.

1.4.3 NITROGEN CONNECTION

1. Connect the supply hose to the hose connector at the rear outfeed side of the machine.

1.4.4 EXHAUST SYSTEM

One exhaust gauge of 160 mm (6.3”) is provided. This should be connected with the customer’s

exhaust system (not supplied by Vitronics Soltec).

• Inflammable and/or explosive gas might develop in the machine because of the evaporation of

the solvent in the flux.

• An exhaust system that functions well, will bring the gases below the explosion concentra-

tions.

• It is therefore necessary to have a sufficient exhaust in the machine.

• The exhaust system also has to be checked continuously on its well functioning.

• The machine is prepared to interfere in the E-stop circuit of the machine with a potential free

contact of the exhaust system. This contact has to be normally open, and therefore closed

when the exhaust functions well (fail safe).

NEVER USE THE MACHINE WITHOUT THE EXHAUST SYSTEM.

1.4.5 PERSONAL COMPUTER

The complete Personal Computer is packed in boxes for transporting. Unpack all boxes and put

the PC in the machine, and the monitor and keyboard on the PC-arm. Connect all cables.

1.5 - MECHANICAL INSTALLATION

Unpacking / Installing mySelective.com CHAPTER 1 7

1.5 MECHANICAL INSTALLATION

After carefully positioning the machine and allowing for sufficient working space we can continue

installation.

The procedures given here are meant as a directive for measuring and controlling the machine, in

order to guarantee that the machine will run as specified.

During some measurements the robot must be set over the camera position. In that case it is

usefull that the robot will function electrically and mechanically in accordance with the specifica-

tions and with the correct software.

For operating the robot, which is necessary to set the robot over the camera position, see User

manual.

1.5.1 MEASURING CONDITIONS

Before measuring the machine has to come at environmental temperature.

If the measurements have to be done otherwise than with solderpots and preheating in a

'switched off' position, it will be notified in the procedure.

1.5.2 MEASURING METHODS

Unless otherwise specified we will make use of standard available measuring tools.

1.5.3 MEASURING TOOLS

• Machine spirit level 0.1 mm/m scale division.

• Square frame spirit level 0.1 mm/m scale division.

INSTALLATION

8CHAPTER 1

1.6 MECHANICAL SETTINGS

1.6.1 FRAME & ROBOT

During installation the machine frame should be set level and at the correct height.

The frame adjustments in combination with the robot axles should be within a tolerance of 0.2

mm/m when the robot is at camera position.

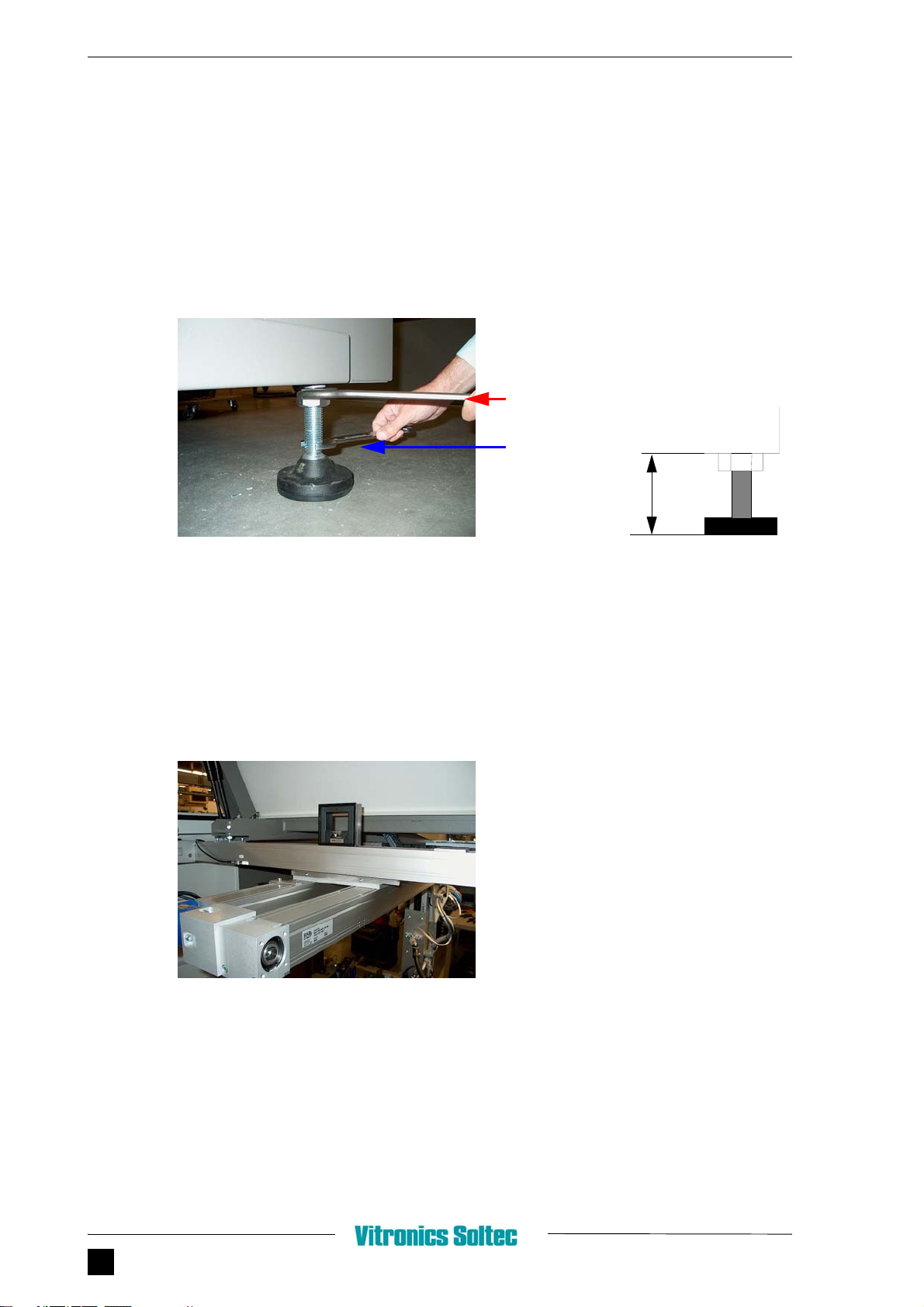

FIGURE 1.7 ADJUSTING WITH LEVELING PADS

1. Release 46 mm nut (A) with open ended spanner.

2. To level the machine, change height leveling pad with 27 mm spanner.

3. Move Robot above camera position.

4. Place spiritlevel on front X-axis.

FIGURE 1.8 FRONTSIDE X-AXIS

5. Adjust leveling pads on front side.

46 mm open

27 mm open

A

B

ended spanner

ended spanner

75 -150mm

1.6 - MECHANICAL SETTINGS

Unpacking / Installing mySelective.com CHAPTER 1 9

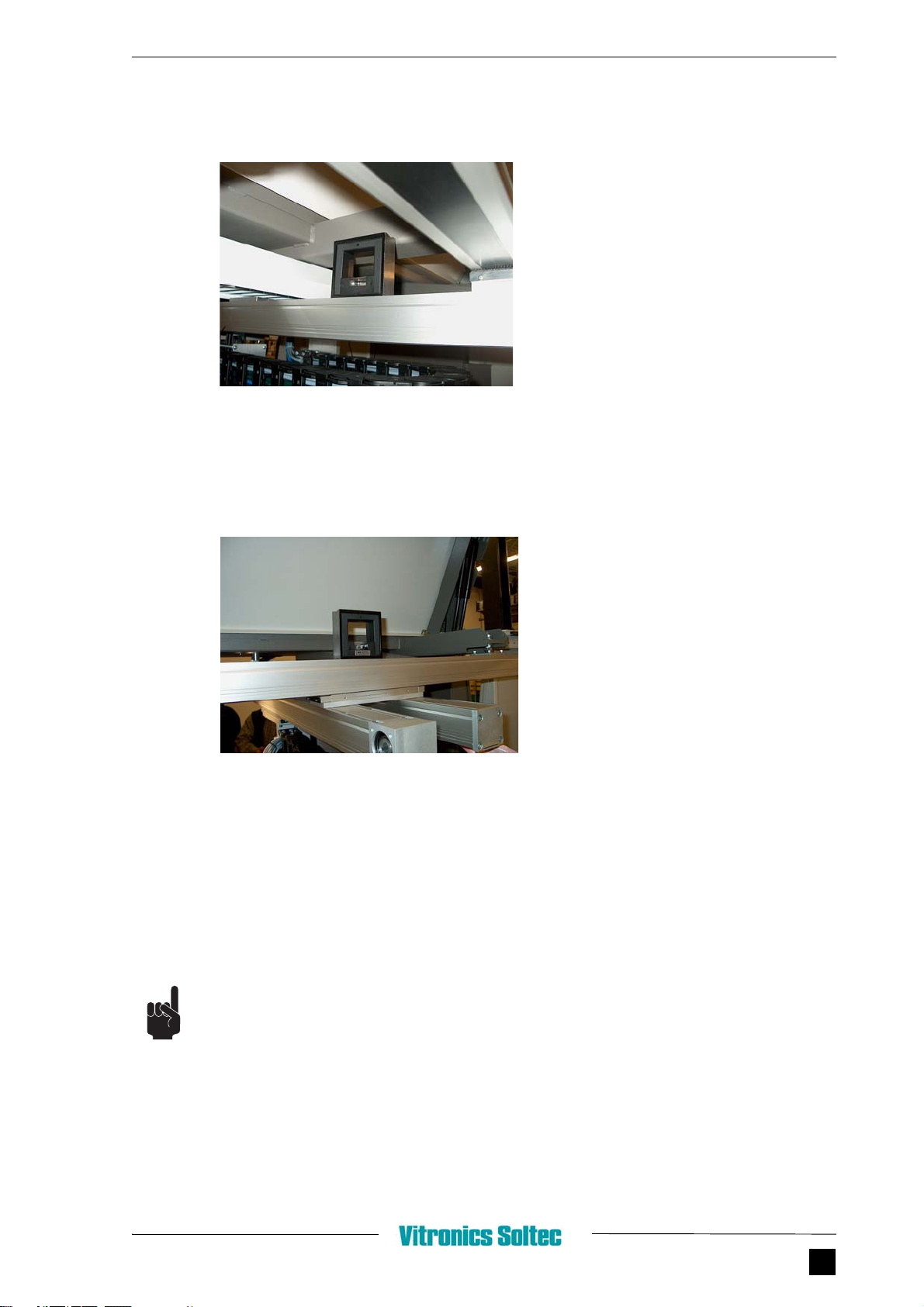

6. Place spiritlevel on Y-axis

FIGURE 1.9 Y-AXIS

7. Level the machine by adjusting the leveling pads.

8. Control backside X-axis.

FIGURE 1.10 BACKSIDE X-AXIS

9. When machine is leveled, tighten the nuts (A). See Figure 1.7.

Don’t forget to remove the spiritlevel after measuring!

After this procedure the machine is mechanically correct installed.

The machinepoints for camera position, conveyor- and fluxing-stations are factory set.

INSTALLATION

10 CHAPTER 1

1.6.2 FILLING THE SOLDERPOT

There are two different ways to fill the solderpot:

1. Filling with granulated solder.

When granulated solder is used: Fill solderpot equally.

2. Filling with solderbars.

When filled with bars, its impossible to melt them on the heated sides of the solderpot. There-

fore the sumps must be removed.

Make sure the bars are placed against the heated sides of the solderpot.

FIGURE 1.11 MAXIMUM SOLDERLEVEL

During heating up and filling the solderpot, it is advised to use in the direct area of the solderpot

an exhaust system.

Always wear protective clothing & glasses when working on the machine.

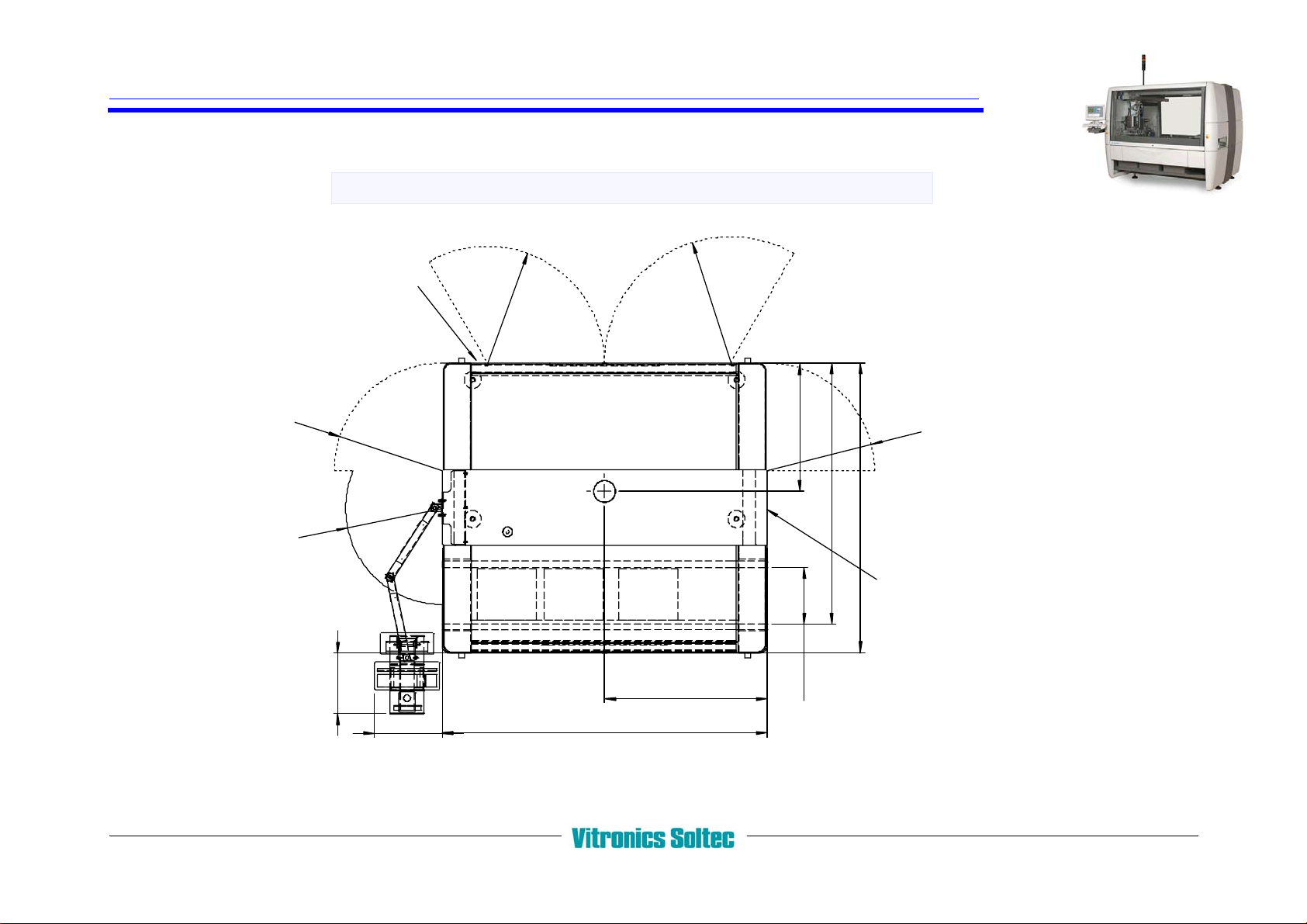

1.7 INSTALLATION SHEET

See next pages.

Max solderlevel

SelectWave

Max solderlevel

MultiWave

Installation sheet

TOPVIEW 6748

2370 (93.3")

max.410 (16")

ca.500 (20")

1185 (46.6")

R920

R850

R780

R780

R700

ca.400 (15.7")

940 (37")

1903 (74.8")

2110 (83")

N2 connection - 6 bar 20m3/h.

3x400V - 50/60Hz - Max. 37 kVA.

mySelective.com

VERSION April 2008

FRONT AND SIDE VIEW 6748

Transp.height 900 -25/+50 (35.4"-1"/+2")

160 (6.3")

1880 (74")

100 -25/+50 (3.9"-1"/+2") 90 (3.5")

1920 (75.6")

ca.1120 (44")

ca.2600 (102.4")

1013 (39.9")121 (4.8")

LIFTING

DISTANCE BETWEEN FORKS

POINTS.

MINIMUM 800MM-1000MM

LIFT ONLY FROM THIS SIDE !!! (= BACKSIDE OF MACHINE)

UNITS IN MM

UNPACK

MACHINE MACHINE

LIFT MACHINE

PLACE

REMOVE

transport

fastening

materials

Installation sheet mySelective.com

Other manuals for mySelective 6748

1

Table of contents

Other Vitronics Soltec Industrial Equipment manuals