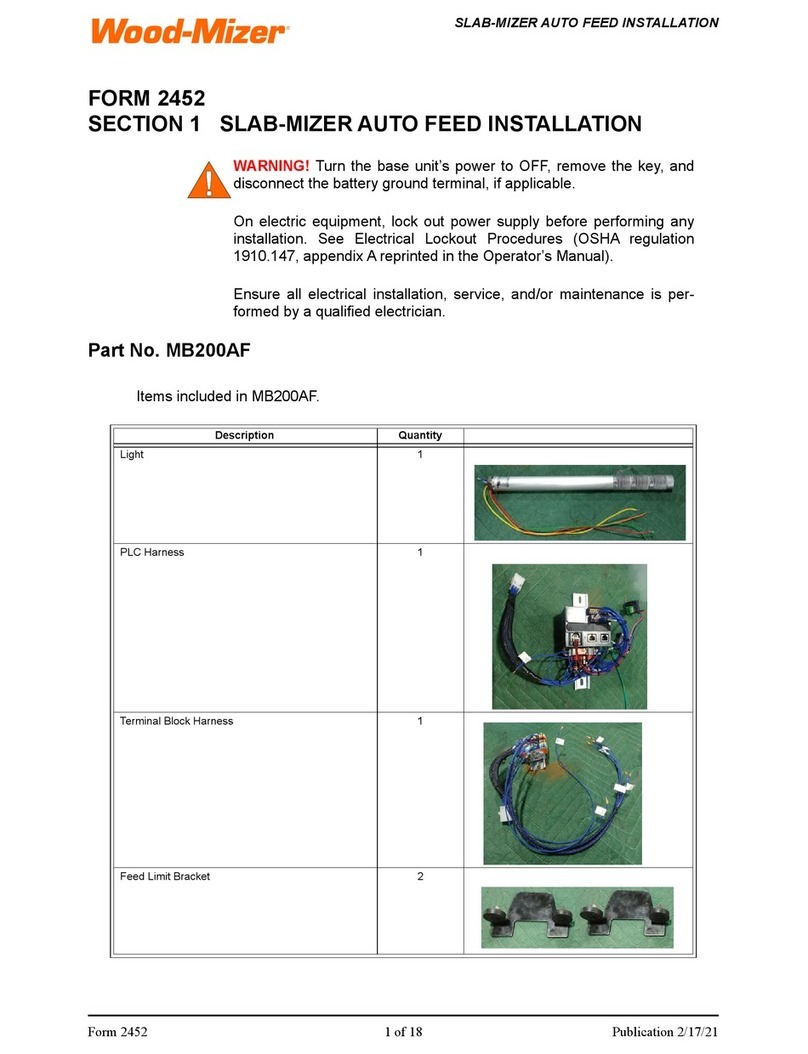

Safety

Before assembling, setting up, or operating the device. Review

this safety information.

Safety Symbols

The following symbols and signal words call your attention to

instructions concerning your personal safety. Be sure to observe

and follow these instructions.

DANGER! indicates an imminently hazardous situation

which, if not avoided, will result in serious injury or

death.

WARNING! suggests a potentially hazardous situation

which, if not avoided, could result in serious injury or

death.

CAUTION! refers to potentially hazardous situations

which, if not avoided, may result in minor or moderate

injury or damage to equipment.

NOTICE indicates vital information.

Safety Instructions

OWNER/OPERATOR'S RESPONSIBILITY

The procedures listed in this manual may not include all ANSI,

OSHA, or locally required safety procedures. It is the owner/

operator’s responsibility and not Wood-Mizer LLC to ensure

all operators are properly trained and informed of all safety

protocols. Owner/Operators are responsible for following all

safety procedures when operating and performing maintenance to

the equipment.

OBSERVE ALL SAFETY INSTRUCTIONS

•NOTICE Read the entire Operator's Manual before operating

this equipment.

• Note all safety warnings throughout this manual and those

posted on the machine.

• Be able to access this manual at all times while operating

this equipment.

• Read additional manufacturer’s manuals and observe their

applicable safety instructions.

• Only persons who have read and understood the entire

operator's manual should operate this equipment.

• This equipment is not intended for use by or around children.

It is the owner/operator's responsibility to comply with all

applicable federal, state, and local laws, rules, and

regulations regarding the ownership, operation, and

transporting your equipment.

Operators should become thoroughly familiar with and comply

with these applicable laws for operating and transporting

equipment.

WEAR SAFETY CLOTHING

WARNING! Secure all loose clothing and jewelry

before operating the slab flattener.

WARNING! Always wear gloves and eye protection

when handling cutters.

WARNING! Always wear eye, ear, and foot protection

when operating or servicing the slab flattener.

WARNING! Some woods require respiration protection

when operating the slab flattener. It is the operator’s

responsibility to know which woods require

respiration protection.

KEEP SLAB FLATTENER AND AREA AROUND SLAB

FLATTENER CLEAN

WARNING! Maintain a clean and clear path for all

necessary movement around the slab flattener and

lumber stacking areas.

DISPOSE OF BY-PRODUCTS PROPERLY

NOTICE Always properly dispose of all by-products, including

sawdust and other debris, according to local ordinances.

CAUTIONS FOR SLAB FLATTENER SETUP

WARNING! Do not set up the slab flattener on ground

with more than a 10 degree incline. If setup on an

incline is necessary, put blocks under one side of the

slab flattener or dig out areas for the legs to keep slab

flattener level. Setting up the slab flattener on an incline

could cause it to tip over.

CHECK SLAB FLATTENER BEFORE OPERATION

WARNING! Make sure all guards and covers are in

place and secured before operating the slab flattener.

WARNING! Be sure the cutter housing and pulley

covers are in place and secure.

KEEP PERSONS AWAY

DANGER! Always be sure the cutter is disengaged and

all persons are out of the path of the cutter before

starting the motor.

WARNING! Keep all persons out of the path of moving

equipment and slabs when operating slab flattener or

loading and turning slabs.

KEEP HANDS AWAY

DANGER! Perform the power lockout procedure

according to OSHA regulation 1910.147 before

changing the cutter or performing any service to the

machine.

DANGER! Always disengage the cutter and shut off

the slab flattener motor before changing the cutter.

DANGER! Keep hands, feet, and other objects away

from cutter guards when operating slab flattener.

DANGER! Stay a safe distance from rotating members

and make sure that loose clothing or long hair does not

engage rotating members resulting in possible injury.