VOIGTLANDER VITO Operating instructions

VNT@ G

Rep araturanweisun g_

Repair ùlanual

Instrucciones para la Reparacion

ïnstructions pour Ia reparation

Individual Part

Pieza individual

Pièce dêtachêe

As

sembly

Pieza premontada

Pièce prênontêe

t58ol-43 @-

Ersatzteile (Sortinent)

Spare parts Assortiment

'surtido de piezas de recambio

Pièces dôtachêes assorties

158o4-1

1

Einzelteil

Voigtliinder A.G.

L.L2,59

VITO C

Ersatztei I Inhaitsverzeichnis. Index

Indice de piezas de recambio. Index des

spare Parts.

pièces d6taehees.

Blett 2

138o1 r o9

tt

o4ro1L6

t35o3 t5

t66oi trl

t45o3 96

VMo

1t811

Blatt 5

158o1 - L4

L5

L6

1g

37

77

8o

L58o2 L5

82L57 57

Zxj DIN t476

ZxL DIN 1476

1',5

III DIN J4o1

VMot38Lz

B1att 4

1J8o1 r o3

ro4

2t

22

24

2J

26

28

2g

'F

))

59

5L

66

/-

a(

6e

69

73

85

84

Kappe

Rahmen

Sucher

Leiste

Schraube

Schraube

Zwischenl age

Jus ti erz ange

Bodenbl ech

Ziihlrad

Ras

tf ed.er

Scheibe

Rûckho

I feder

Folie

Scheibe

Folie

FI achsenks

chraube

Kerbnagel

Kerbnagel

KugeI

Montagescbliis seI

1J8o1 r o5

ro7

Zo

46

52

54

56

57

58

_6L

6tr

86

L27o1, 99

L,5 DrN 6799

81165 57

8542o 57

1/t6" rrr DrN

15801

:ii,

44

88

15802

-\l

t7

126o2 t5

1,Jxlo DIN LI*75

1,Jr8 DIN 11181

83L3L 57

81444 57

Scheibe

Fi Immerkscheibe

ZyL. -Schraube

BIatt_ 5

Zahnrad

Zahnstange

Riickspulhebe I

ZyL. -Ans. -Schraube

Sperrkl inke

iiberl ast'f eder

Lagerbl ech

Ànsatzsehraube

%yL.-Sehraube

Tas

te

Schaftschraube

Scheibe

Feder

Bz. -Scheibe

ZyL, -Schraube

ZyL.-Ans'-Niet

54ot Kugel

Blatt 6

Transportro I I e

Zâhlwe 1

I e

Druckfeder

Zahnradbuchse

Feder

Biickwand

Andruckplatte

Deckbl ech

Zuhal tung

WinkeI

Gleitrolle

Fed.er '

Spanns

ti ft

Spanns

ti ft

ZyI-.-Niet

Schraube

2

L26LL - t2

145o1 r t7

81165 57

Mi tnehme

r

Aufzughebel

Riickspulknopf

BoIz en

Àchse

Abdeekbuchse

La.gerscheibe

Feder

Drahtkl amoer

Klinke

Spule

Feder

Kappe

ZyI. -Ans. -Niet

Achse

Feder

lVinkel

Scheibe

Fed.erring

V o i g t 1 ii n d e r A.G.

2

Blatt 7

1JBo1 r o2

ro6

ro8

lB

r*3

59

63

65

74

75

76

78

t3813 37

38

1Sx4DIN 1481

1,4x5D

IN 55L

81165 57

Gehâuse

Spe

rrhebe I

AusIôseschieber

Tubus

Gewindestift

ZyL.-Ans. -Schraube

Druckfeder

Sche

ibe

Druckfeder

FoIie, rechts

FoIie, links

Isolierstreifen

Sche

ibe

Spannwel 1e

Spanns

ti ft

Gewindestift

Schraube

377 G49

47o 1t543

o 475 587

555 GZo

555 171

597s G96

597 133

BIatt I

I385J r o2

18

L9

2o

2T

t,4xJ DIN 551

81!3o 57

295 t39

597

s L37

597

e tJt43

Vordergl ied

Decks

cheibe

Frontplatte

Skalenring, deutscb

Skalenring, feet

Gewind.e

stif t

ZyL .-S chraube

BIatt 9

Lj813 r oi Verschlu8trâger

25 Blitzlichtbuchse

29 Befestigungsring

3o Abstimmring

16 Lôtfahne

83L35 57 ZYI .-N i e

t

oo 476 t35 LinsenkoPfschraube

555 L75 SYnchro-Kontaktfeder

555 LL6 Sektoren

555 U8o Sektorenring

545 I3o Feder f. Auslôsehebel

K18 1J2

257 142

o 257 L46

2Bo 1,28

146 -U85,1

375 -119'

t

Voig t1ônater A.G.

t,t2,59

Vito C(ryp" 1lB)

Blatt 2 a

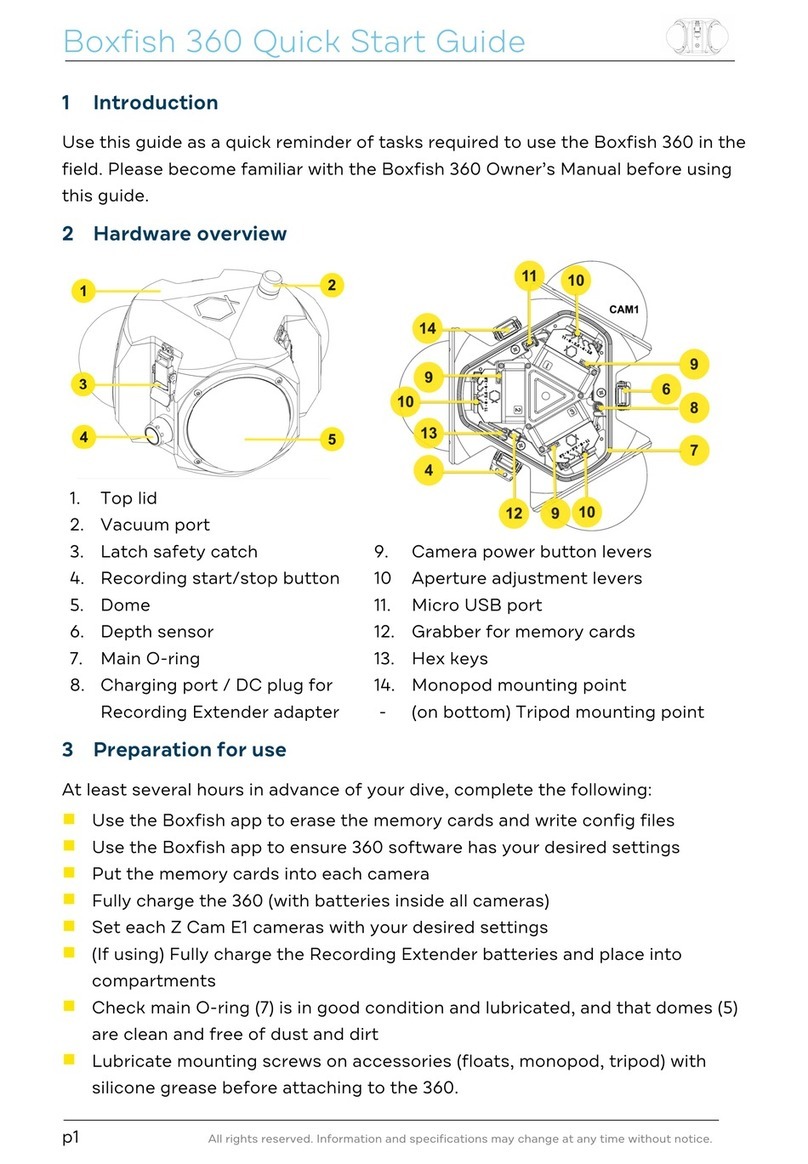

Beim tr{ontieren tles Schalthebels 11801-20 (siehe Blatt Nr.5) mufl

darauf geachtet werden, da8 die iJremsfeder tiB0L-29 (siehe Dlatt

Nr.4) aen $chalthebel nicht behindert.

ller lliickspulknopf LjBOf-2t mufJ

nach oben und unten frei gle iten,

nôtigenfalls ist die ll,astklinke (.* Schalthebel) nit der Zange

Vl,{o LlïtI z\ richten. Dadurch darf rtie Rastklinke in der Ril le

vom Rtckspulknopf keinen Druck verursachen.

Blatt 1 a

Wenn derrufzughebel 1J801r0t* demontiert wird, mu8 in jedem FalIe

tlas BodenbIech llB0l-14 abgeschraubt werden. IJas ZâhIrad I380t-15

abnehmen. Geben Sie obacht, in .cler Gehâusebohrung l iegt eine klei-

ne Iiugel 1.5 III DII,,I5401, d.ie unbertingt wieder montiert vierden

muf;l.

Die lltckholfeder tjBOL-\7 kann nur ausgebaut rverden, indem der

Iierbnagel 2 x 4 DIN L476 ein Stiich herausgezogen n'ird, Dies trifft

auch fûr den Kerbnagel 2 x J DIN 1476 z,tr.

Bei der \iontage d.es rruf zughebels mulJdie tltckhol f eder mit dem

iVerkzeug V[{o L3SL2 und einer Iimdrehung Vorspannung auf die Achse

des Àufzughebles gedriickt werden.

Das freie Ende d.er f'eder wird urrter den l(erbnagelkopf gelegt.

JeLzt den lierbnagel hineindriicken.

Blatt 4 a

ûei der l,{ontage ùes lttckspulknopfes tTBQt-zl ist auf den Schalthebel

I38Ot-20 zu achten. Siehe Hinweis auf Blatt 2 a,

Beim h{ontieren d.es "ufzughebels 13801r04'mul} auf folgendes geachtet

werden

L. Die Bohrung d.er Aufrvickelspule fi8AL49 mu8 gut nit Vaseline

gefettet werden.

2. Der Iiitnehmer 1JB01r0J rnu8 nit gespanntem I'ilntransport und

Verschlrrg so eingesetzt werden, tl.a0 die Zahnkopfauslâufe'Brl

(., hleinen Zahnkranz) parallel zur Gehâusekante verlaufen.

r,Venn

nicht, d.en lriitnehmer anheben und den gro8en Zahnkranz um

ein oder mehrere Zâhue vor bzw. zuriickverSet'zen.

ifichtig! I'ien1 Ihnen Iiameras zur iteparatur vorliegen, bei denen

der lileine Zahnkranz auf dem Àlitnehmer nrit o.B nun

Blech ausgefiihrt ist, tauschen Sie rlen I'litnehmer ge-

gen einen-mit kleinem, starken Zahnkranz aus (siehe

Âbbi I dung)

j. Aufzughebel 11801r04 uontieren. (Denken Sie bitte daran, da8

die lttckholfeder 1380L-37 am Gehâuseboden eine Umdrehung Vor-

spannung haben nau8)

. JeLzt, darf der .rufzughebel nur ein geringes

Spiel aufweisen. Ist, dies nicht der I'atI, kann tl'as Spiel mit,

der Sperrklinke L3801-52 vermindert werden. Die Sperrklinke

darf allerdings nicht zv stark gegen den grollen Zahnkranz am

\,1.itnehmer dri.icken.

V o i g t t â n d e r A.G.

YlTO C

Page 2 a

When mounting lever Lj

that its movenent is n

pase 4),

The rewind knob 11801-

and if necessary, the

ted with the .pliers VM

pressure on the groove

Pase J, a

l{hen the rapid. wind le'

plate 15801-14 has, at

filn counting wheeL 13

t.5 III DIN 5401 situa

again when r€-êssenbli

dismantled by pulling

DIN t476. When re-asse

has to be pressed toth

tool Vtr{o

tlÙtL and to

The free end of

2 x 4 DIN t476 this s

and, the

Page 4 a

I{hen as

sembling

onpageZawith the re

re fer

l{hen mounting tbe

points should be

1) The

with boring of the f.

vaseline.

2) Peg 15801 r 05 shou

transport and shutt

on the small wheel

If this is not the

rim forward. or back

Important! When re

on the

against

illustr

3) Àssemble rapid wind

spring t58OL-37 at.

tension of on turn)

now should be very

backlash can be red

too stronglY agains

cause the mechanisr

ism would be affect

rapL

obser

(rype 158)

801-20 ( ." per page 5) care has to be taken

ot handi""ppàA by spring L|B0L-29 (t" per

2L should freely slid.e uqwards and downwards

catch on the lever 11801-20 should be adjtl's-

o tJBtL and this catch must not exert any

of the rewind knob.

ver 15801 r O.tr

is dismantled', the bottom

any raf,e, to be disnantled too. Remove the

801-15. Take eare that the srrall steel ball

,ted. in the boring of the bod'y is inserted'

rrg. The recoil spring t38Ùl-37 c&n only be

oot a bit pins 2 x 4 DIN L476 and 2 x 5

nbling the rapid. wind lever this recoil spring

re axle of the rapid wind lever by means of

be pretensioned bY one turn.

rpring is to be put under the head of pin

r pin i.s then pushed into its ho1e.

wind knob L180L-2t mind

ence to lever 13801-20.

d wind. Iever 1J801'r 04,

ved.:

iln reel tiBÙ]--5g should

what has been said

the following

be weIl greased

nld be assembled with the tensioned filn

Ler such as to have the erests of the teeth

rim rfBï paralle1 to the edge of the body.

case, Iift.the pegand turn the large gear

kward by one or more teeth.

epairing cameras the small gear rim of which

p"g is mad.e from 0.8 nm sheet replace the peg

t- one with a small and thinner gear rim, as per

ration.

tl lever 11801 r 04. (Uina that the recoil

the bottom of the body should have a pre-

). T.he free rnotioa of the rapid wind lever

slight only. If this is not the case, the

duced. by catch t58oL-52, but this must not press

st the large ggaT Ilm on tlle p-e-g-a1-this would

tn opôrating t;- h;rd and {Ëe iet-ease néôtrail--

ted. CV o i g t l â n d e T A-G;

81. Gez. G"dÎ. Dat.

1f flfr ,Wta,L.t2,5t

VTTO

&) \1'asher 1i801-Si serves f or nialcing the rapid wind Iever gl iding

freely and protecting it fron being hantlicapped by angle L380I-73.

l'urthermore this ryasirer prevent,s axial backlash of the rapid rvind

Iever so that it does not scrape on the cailera top.

5) The friction clutch of the film transport has to be checked rvith

a test rveight from 100 to 200 gr. and it rnust in no case be smal-

ler or higher to this. In case it operates too freely loops ol'

the f itrn (clouble exnosures) are unavoitlable, Does it work too

irard the distance Letlveen the frames becones irregular.

The checking has to be made as follows: talre a film strip of 5A cm

length aryà'wind it around the takirrg spool. then place the caneras

so obliqe ttrat the film is hanging verticalliy to the floor, A

weight of 150 gr approxinately then should be fixed to ihe film

ancl now the taking spool should move very slon'ly, even if the

rveight s.lowly, the friction cluch rvill have to be adjusted by me-

ans of spring 11801-b4.

Pâge 6 a

The transport wheêI 13801-40 has to be assembled. such as to spring

slightly in axial direction and if necessary adjusted by means washer

12601-43 aL the inside of the bottom of the bod.y.

l''age 5 a

Prior to mounting rack L}BOL r 07, the stide faces should be dreSsed

burres and weII greased.

Page 7 a

Unscrew the 4 screws 8116 5-57. Remove shutter tJ817 r 00, Assembly of

shutter is to be made the other way round. Mind centriug pins L.5 x 4

DIII 1481 and pay attention to the followingt

a) TIre tensioning bar L3833-38 has to be inserted such that the 2

pins on this bar are parallel to the longitudinal side of the edge

of the camera body when the filn transport is actuated. Now insert

the shutter provisionally, but not the tube 13801-38. The tensio-

ning bar is to be moved in its axial direction from behind,

Should there be axial backlash of the tensioning bar this has to

be reduced by means of washers LJBll-J| to a reasonable d.egree.

Itemove shutter.

b) The tube LJ80L-38 has to be inserted into the notch at the body

and the shutter and its height should only be such that there is

a slight tension between body and shutter. If necessary the height

of the tube has to be reduced by grinding.

c) The shutter ryhen inserted. must not

ase lever 13801 r 08.This release

the synchronisation cable must not

assembled,

Illustration shows newest version of the Iocking lever 1J801106

which night also be used. for replacing such levers having a stop

rfarr. In that case bore a hole into body andcut a thread for screw

81444-57 as per page 6, which demonstrates where screw 81444-57

and spring 15801-88 have to be nounted.. lfhen transport and. release

of canera are not functioning properly, this night be due to stop

rfar being bent and it is recommended to exchange lever against new

one as illustrated.

,exert any pressure on the rele-

lever should gI id.e easily. Also

be janned when tire shutter is

m"

VITO CVoigt 1ônder A,G.

L.I2.59

133

03-

35@ 13801r09

\\

\

2x

166

05

-

rr1

@

1+503

-96

136

0+-16

138

04

r01

ffi

138

01

-13

V o i g t I ii n al e r A.G.

t.12.59

\;

138

02-15

2x\ DIN

1+76

19801

-

1?

138

01-3?

139

01

-1+

I

I

-E

ô2x

82157

-57

,r{

138

A1-$

2x3

DIN1476

138

01-80

tr!&b,ilN

5tlo1

\ ^lt+rr-

1?901

-

15

138

01-',/,7

Voigtlânder A.G.

L.t2.59

regor

-ss

O Ë

rzor-rz-@

C>

(@

13801-21 K-ml-|||||||Ïl

A

orr

os-

szGL

?_

_

6 ,.r.r_r,

13801-?5

13801-51c@,-.

,-\

(A)

\_/

e 13801-6

13801-25

13801-28

reeor-zo@

13801-29

2x12+O2-20

2x1?801-67

138

01-66

13601-6E

13901

-69

13901

-

22

-1

|

138

01

rOh

I

V o i g t I ê n d.e r A.G.

13801

-57

138

727r*il

2181165-57

@_ 9

U

I

136

01-

56

138

01-58

138

A1rO7

9i

<b

I

i

?

-t

138

01-20

1,5

PIN

6?99

@

13801-+6

138O1

rO5

138

01-52

83rl

20-5'l

13901

-61

13901-

6tl

Voigtliinder A.G.

VITO Ct .

t2,59

3x

831

31

-57

2x

1.518

PIN1t+81

13801

-40 |

13801-+1

2x

13802-13

1,5x10

DIN

1+75

Voigt Iiincler A.G.

t.L2.59

13801

-74

138

01-

t$3

138

01

r

06

138

01

-76

1,5x+

DIN1+81

ierj-380L:95

139

01-75 iEt,

rË

;Ë 13801

-63

'e t

139

33

-38

13801-38

4x811

65-57

wE

i

i

13801-?E

138

A1r02

13833

-37

M1.4x

5 DIN

551

Voigtlâniler A.G.

138

01r08

2x13801-59

-o

@

@

D,iiqô

T

r

t

13833-?ot21

31

811

30

-57

138

33

-

19

138

33

-

16

295

-139

5?7s-U1t+?

597

g- 137

*æ

"Y/

\o -/

--,

K.." )

$\/

V o i g t t ii n d e r A.G,

L

.72

,59

470-U

543 5979

- V

96

0r+75

-387

375

- 119.1

3+6-

U85.1

0257

- 146

597

-133

K1E

-V2

13833

-25

377-

A+9 00

tl76

- 135

$ynchro

-

KovrtqktfederNr.555

-113

Sektoren Nr.

555

-116

9ektorenring

Nn

555-U

80

FederfùrAuslôschebel

Nr.

3tl5

-130

555

-

1?3

Tylinderyrief

Lôtfqhne

Befestf

gunqsring

Absti

nnmrirr

g

257

-1+2

555

-129

280

- 128

- 93135

-57

- 136

?3-36

- 13939-29

- 13E33

-30

VITO CVoig tlânder A.G.

t.t2.59

:

T

t

VIT@ GL

Beparaturanweieung

Bepair

Ins truc ti one

Ins trucc iones

ManuaI

pour Ia reparation

para Ia Reparacion

t4tt5-16 @

rti

Individual Part

Pièce dôtachôe

Pieza individual

Assembly

Pièce prênontée

Pieza premontada

Spare parts Assortiment

Pièces ùôtacbÉes a6rorties

Surtido de piezas de recambio

Monti ertes

t\Lo7 -2t

Einzel tei I Ereatzteile ment)

V o i g t I ii n d e r A.G.

vtT() L-2^6o'

141o7ro2 Kappe

ro5 Rahmen

t26ot-55 Schraube

t26tL-L2 Scheibe

tjJoS-\5 Linsenschraube

145o1177 .h'i

Inmerksche ibe

t66o5-47 Senkkopf schraube

Blatt J

141o4ro1 Albada-Sucher

llrloJroo Beli-Messer

ro1 Platine

-18 Schieber

-t9 Buchse

-2o Buchse

-2L Bûgel

t2611-2o Scheibe

1J8o1-86 Scheibe

81

148-57 ZyI .-Schraube

81165-57 ZyL.-Schraube

M1,Jxt DIN 551 Gewindestift

Blatt 4

t4733roo

1J8oI-JA

-6r

-64

-78

1383t-57

-38

8rL65-57

Ers atz te i I -Inhal

fnder des pieces

Blatt 2

tsverzeichnis. Index

dé

tachêes, Index rle piezas de recambio.

Blatt 6

14L33ro3 Versch

luB-Triiger

-23 Pronto LK-xJt*JgZ,8f 5o

16il

-25 Achse

-29 Belistift I

-3o Belistift II

-1L Belistift III

o

o2J5-t39 Frontpl attenring

l r5 DIN 6799 Sicirerurigsscheibe

Blatt 5

t4l35roj Vers c

I ufltrâger

-L5 Abdeckring

-t6 Deckscheibe

-17 Frontplatte

-2o Skatenring n

-2t Skalenring feet

-22 Schaftschraube

-23 Pronto LK-x547e

16P

-24 Pronto LK-x5h7e

15,9 g

L585Jro2 Vorderglied

-16 Vorderfassung

-L7 Linsenhalter

Lanthar 2r8/Jo irn Pronto

LK- x 547 e

Tubus

Tas

te

Schaftschraube

Isolierstreifeu

Ring

Spannwe

I I e

ZyI. -Schraube

z

,8f

5o

z

,8f

5o

VoiE ttËnder A.G.

vrT0cr t .

.2

.6o'

r

t

E

Â

-.1----

Â

'I I

rJ-

E

-l

;

r adjusting the exposure meter a test unit MPr 297 and an

xiliary test cover is necessary.

P.ut sensibility to L5 DIN = 25 ASA.

Set aperture ring to 4, tine ring to B (corresponding to

Iight value 7). Now follow pointer tDr and needle of ex-

posure meter nust superimJlose and point to mark E. If this

is not sor turn adjusting Ecrelr'I{ I.7 x 4 DIN 55L until

pointers aI ign. Take care that adjusting screrr carl be turned-

ieariily lrut not too easily. If it tuqns too easily, bend up

flap F.

Set aperturring to 16, time ring to I/6A (cor"esponding to

light value 14). Both pointers should. aIign. If not, turn

adjusting screw as under 2.

Set aperture ring to 4, time ring to t/60 (corresponding to

Iight value 10). I{ere again both.pointers should superimpose.

If necessary, turn again adjusting screw as under 2,

Checking of all light values as per 2) 4) has to be repeated'.

\ïith all values (7, 10 and. 14) the aperturê ring has to be

set from left and right to the apertures \ and L6.

A tolerance of + 1/2 light value (aperture) is to be considered.

Adjusting screw }r{L.7 x 4 DIN 551 then is to be locked' with

gl ue.

Vito cL (ryp" 141)

Page la

The najority of spare parts for Vito CL (rnodet 1l*1) it the

same as for Vito C (motlel 1J8). This repair manual only contains

those parts and repair instructions specific for Vito CL. As

concerns all other d.etail=r. please see instructions for Vito C.

Pag,e 1

Assemblv of Exposure Meter

\Vhen as-*embling the exposure meter, pull out rack tC

I to the

stop. Take care that cog rvheel tBt fully grips into rack 'Ct.

If this is not sor adjust with disk L26L1-20 and press exposure

meter simultaneously against rack rCt.

Àd.'iusting of Exposure -lfeter

3)

4)

5)

::

1)

2)

6)

V o i g t l â n4

t .2.60

tT{}

ro

/

d

16605-41

2x

126

01

-55

12611-

12

V o i g t I Ë n d e r A.G.

vlT(} w,

I

I

I

I

I

Y 13303-35

o

LF ro

lt+to?

- z't

4l I@

16605-111

'

-.---1

2x

12601

-5t

12611-

1L

V o i g t I ii n {_:-:--l' G.

15.

l 0.60

811+8

-5?

81165

-s?@ g1+101

-

21

sr]ss-sz@

I

ltF1-o+'otl

gr | 12611-20 p

I.

t+t01

-n .îi

e *10z-zo

@ Éso1-86@

r J t

vlro cr V o i g t I ii n d e r A.G.

Bl, Gez. c"É. I Dat.

,.Ç0,,A. | | .2,6o

Other manuals for VITO

1

This manual suits for next models

2

Table of contents

Other VOIGTLANDER Digital Camera manuals

VOIGTLANDER

VOIGTLANDER Vito III User manual

VOIGTLANDER

VOIGTLANDER VF101 User manual

VOIGTLANDER

VOIGTLANDER Vito II User manual

VOIGTLANDER

VOIGTLANDER BESSA-R User manual

VOIGTLANDER

VOIGTLANDER Perkeo II User manual

VOIGTLANDER

VOIGTLANDER BESSA-R User manual

VOIGTLANDER

VOIGTLANDER BESSA-R2A User manual

VOIGTLANDER

VOIGTLANDER Bessa III 667 User manual

VOIGTLANDER

VOIGTLANDER VITORET DR User manual

VOIGTLANDER

VOIGTLANDER BESSA-R2M User manual