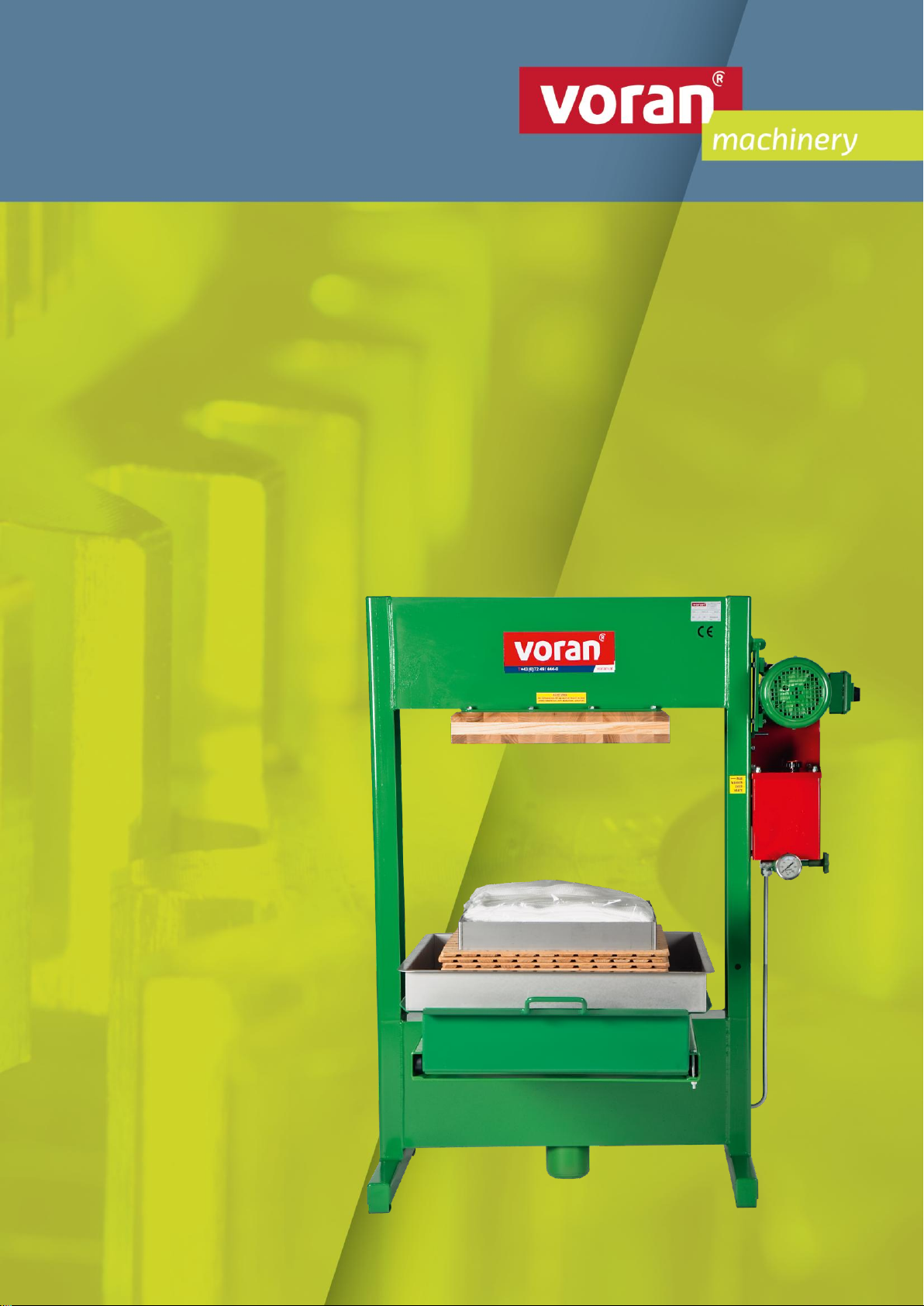

Packing Press 100 P2

Version: 111300001, M0004459B

Date: 13.12.2013 - 2 / 44 -

1BASIC SAFETY PRINCIPLES..............................................................................................................................4

1.1 KEY TO THE SYMBOLS.......................................................................................................................................4

1.2 GENERAL SAFETY REGULATIONS........................................................................................................................6

1.3 SELECTION,QUALIFICATION AND RESPONSIBILITY OF OPERATING STAFF ..............................................................6

1.4 ORGANISATIONAL MEASURES ............................................................................................................................7

1.5 SAFETY REQUIREMENTS FOR THE OPERATING STATE..........................................................................................8

1.5.1 Servicing/repair operation.......................................................................................................................8

1.5.2 Normal Operation....................................................................................................................................9

1.6 SAFETY DEVICES ............................................................................................................................................10

1.7 REMNANT RISKS .............................................................................................................................................12

1.8 CORRECT USE................................................................................................................................................13

1.9 INAPPROPRIATE USE.......................................................................................................................................13

1.10 TRAINING RECORD..........................................................................................................................................14

2TECHNICAL DATA.............................................................................................................................................15

2.1 TECHNICAL DATA –MACHINE/LINE AS AN ENTIRE UNIT .......................................................................................15

3TRANSPORTING AND SETTING UP THE MACHINE / LINE...........................................................................16

3.1 NOTES ON TRANSPORTING..............................................................................................................................16

3.2 NOTES ON ASSEMBLY......................................................................................................................................17

4STARTING UP / RE-STARTING OF THE MACHINE/LINE...............................................................................18

4.1 GENERAL.......................................................................................................................................................18

4.2 CONTROLS AND SETTINGS WORK BEFORE FIRST STARTING UP/RE-STARTING OF LINE..........................................18

4.3 OVERVIEW OF LUBRICANTS.............................................................................................................................19

5FUNCTIONAL DESCRIPTION............................................................................................................................20

5.1 FUNCTIONAL DESCRIPTION –PACKING PRESS 100P1......................................................................................20

6OPERATION .......................................................................................................................................................20

6.1 GENERAL.......................................................................................................................................................20

6.2 OPERATION –MACHINE /LINES COMPONENTS .................................................................................................21

7ELECTRICAL SYSTEMS....................................................................................................................................23

7.1 ELECTRICAL SICUIT DIAGRAMM ........................................................................................................................23

8HYDRAULIC .......................................................................................................................................................24

8.1 HYDRAULIC DIAGRAMM....................................................................................................................................24

9FAULT AND ERROR ANALYSIS.......................................................................................................................25

9.1 GENERAL.......................................................................................................................................................25

9.2 FAULT AND ERROR ANALYSIS –MACHINE /UNIT COMPONENTS...........................................................................25

10 SERVICING AND REPAIRS...............................................................................................................................26

10.1 GENERAL.......................................................................................................................................................26

10.2 SERVICING AND REPAIRS REPORTING...............................................................................................................29

10.3 MAINTENANCE INTERVALS...............................................................................................................................30

10.4 SERVICING AND REPAIRS –MACHINE /UNIT COMPONENTS.................................................................................32

10.4.1 Cleaning................................................................................................................................................32

10.4.2 Replacing the cylinder collar.................................................................................................................32

10.4.3 Ventilating the hydraulic system ...........................................................................................................33

10.4.4 Tightening the strap ..............................................................................................................................34