muffler clockwise will increase the temperature and flow of the cold air. The black muffler may become

warm. An optional heat shield is available to protect the user’s body from the hot exhaust air, if desired.

(See Table 1).

The Cooling Tube can supply chilled air to the Vortec Cooling Vest or to a hood or helmet. When purchased

with the vest, the cooling tube is inserted into a sleeve on the vest; when purchased separately, the Cooling

Tube is supplied with a belt, with the Cooling Tube in a horizontal orientation on the user’s waist. If it

is desired to reposition the Cooling Tube so that it is vertical on the waist (for connection to a hood or

helmet), first remove the white plastic button at the end of the belt by pulling the two halves apart. Remove

the belt assembly from the metal belt bracket and then reattach it to the bracket through the alternate

slots. Loop the end of the belt through the male side of the buckle and reattach the white button in the belt

hole by pushing the two halves together. See Figures 1 and 2.

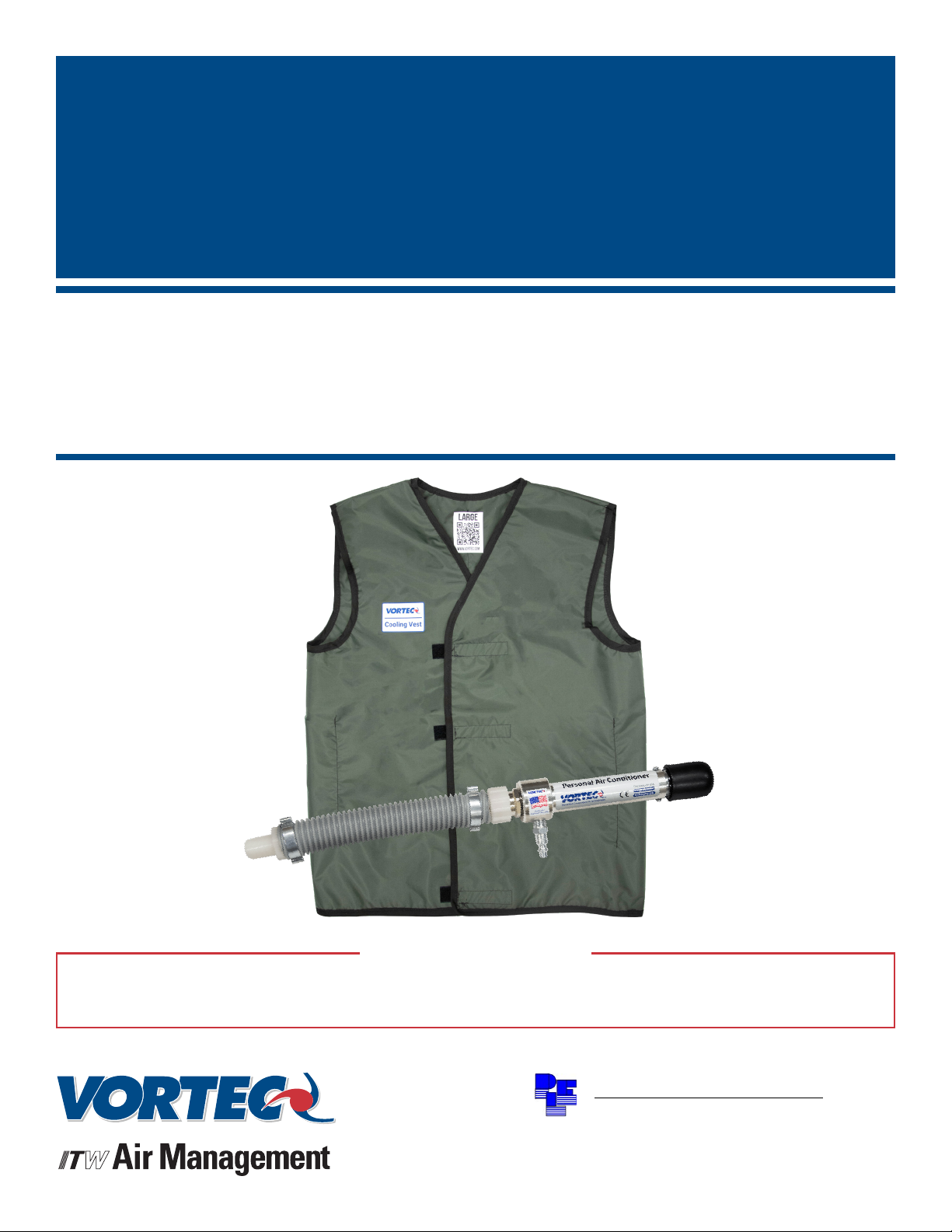

Cooling Vests

Upon receipt, inspect the vest and contact your Vortec representative immediately if you suspect

damage of any kind to the vest. Once the vest is placed into service, it may not be returned under any

circumstances. The Cooling Vest comes with the Cooling Tube already inserted into the sleeve on the vest.

Put the Vest on, and secure the front of the vest with the four Velcro fasteners. Be sure to leave enough

room to comfortably move in the vest. Connect the Cooling Tube to the air supply for cooling to begin.

The Cooling Vest may be used under welding leathers, coveralls or other protective garments, but the warm

exhaust air from the Cooling Tube must be vented outside of the garment.

Maintenance

The Cooling Tube may be disassembled for cleaning by removing the cold outlet fitting. Remove the O-ring

and the red, blue or brown nylon generator. Inspect the parts and clean or replace as needed (see Table 1

for replacement items). When reinstalling the components, it is important to torque the cold outlet fitting to

100 inch-pounds (11 newton meters) to ensure proper sealing. Check the filter elements in the compressed

air filter(s) and change if necessary.

Troubleshooting

Insufficient airflow may be caused by the following:

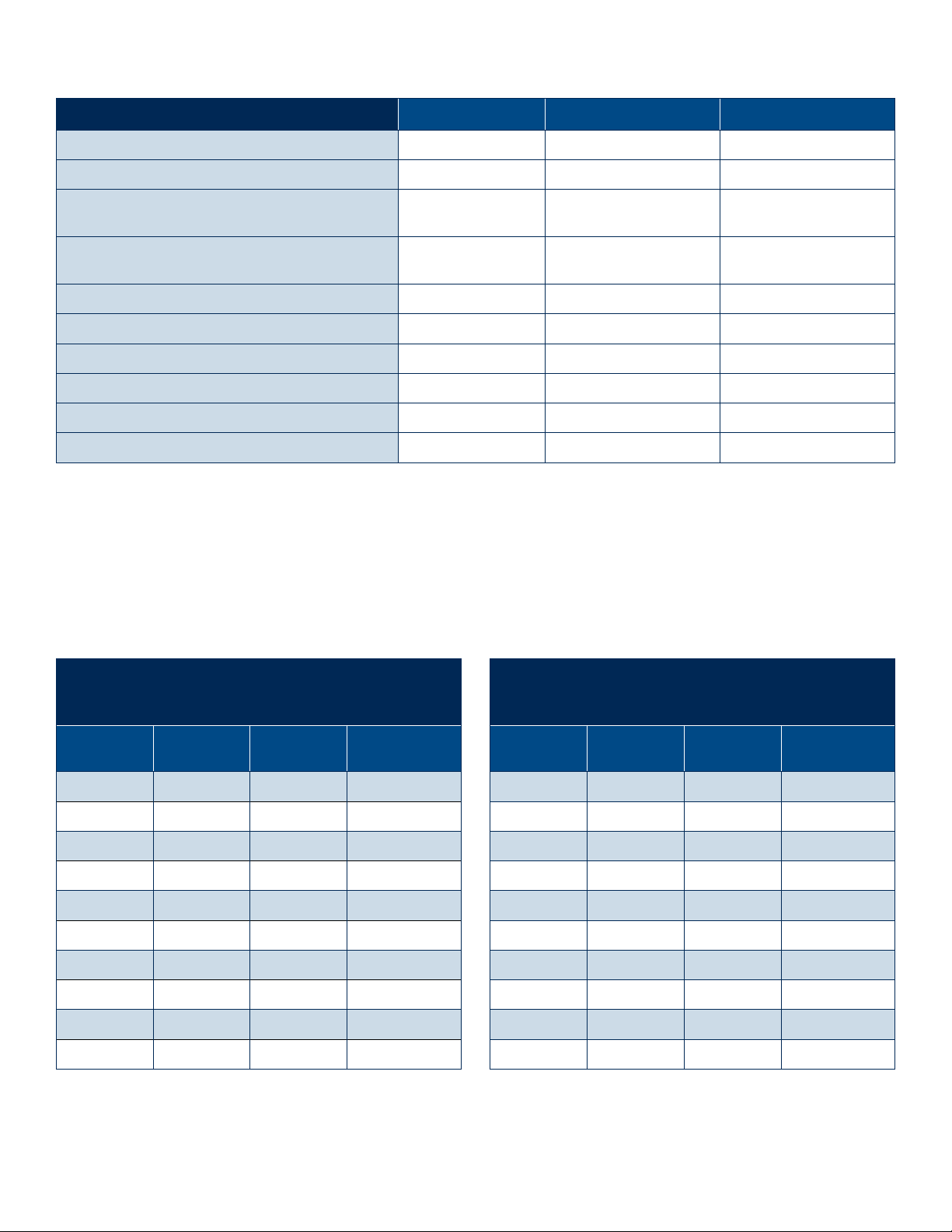

1. Undersized compressed air line size (See Table 2).

2. Compressed air hose too long (excessive pressure drop through hose).

3. Compressed air pressure too low.

4. Insufficient compressed air volume.

5. Partial or complete blockage of internal compressed air path, due to dirt or moisture freezing in the cold

air stream.

6. Loose cold outlet fitting (if disassembled for cleaning).

If trouble persists, please contact Vortec at 1-888-754-6329

Limited Warranty

Vortec compressed air products manufactured by ITW Air Management will be replaced or repaired if

found to be defective due to manufacturing within ten years of the date of invoice. Cooling Vests are not

covered under by this warranty if the vest has been removed from the packaging and placed into service.

Refer to our website www.vortec.com for full warranty details and limitations. ITW Air Management makes

no specific warranty merchantability or warrant of fitness to a particular purpose.