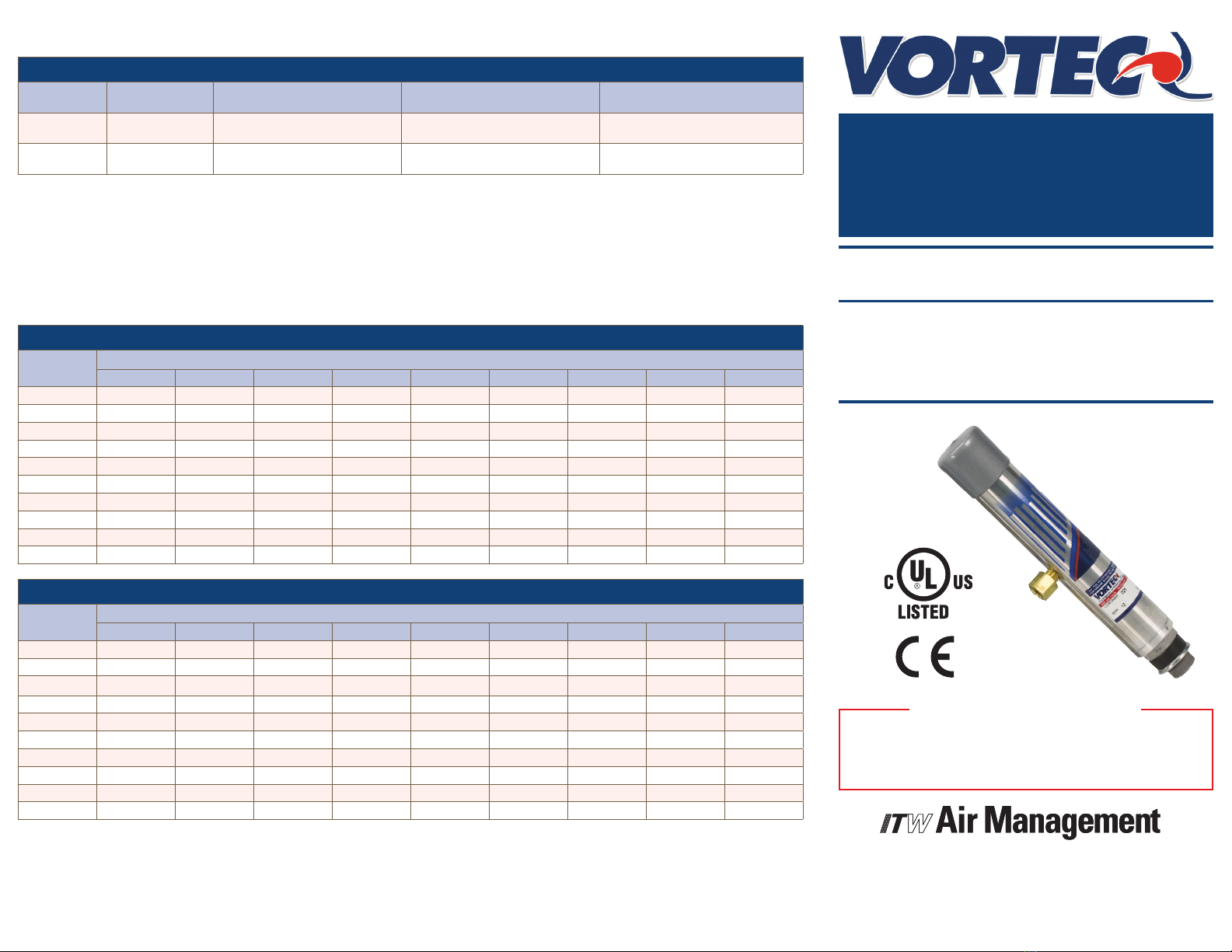

intrOductiOn

AVortex Cooler is designed to use ltered compressed air to

cool industrial cabinets without the use of any refrigerants.

An internal Vortex tube lowers the temperature and

pressure of the compressed air supplied to the enclosure.

Hot air in the cabinet is vented to the surroundings through

a built in relief valve in the Vortex Cooler.

Vortex Coolers can be used with or without electric

thermostats and solenoid valve.

cOMpreSSed air SuppLy

The compressed air supply must be ltered to remove

water and dirt using a 5 micron or smaller lter. Failure

to use a lter may cause clogging (and freezing) of the

compressed air paths inside the Vortec product. Filter

recommendations are given in Table 1.

Filter elements must be changed on a regular basis.

Frequency of change is determined by the condition of

the compressed air supply. Filters should be installed in

the compressed air supply line as close as possible to the

Vortec product.

The appropriate size of compressed air supply line should

be selected to ensure optimal performance of the Vortec

product. Please refer to Table 2 to determine what supply

line size is recommended for your application. Contact

Vortec at 1-800-441-7475 for further assistance.

Maintenance

Vortec Cooler systems have no moving parts and can be

disassembled for cleaning.

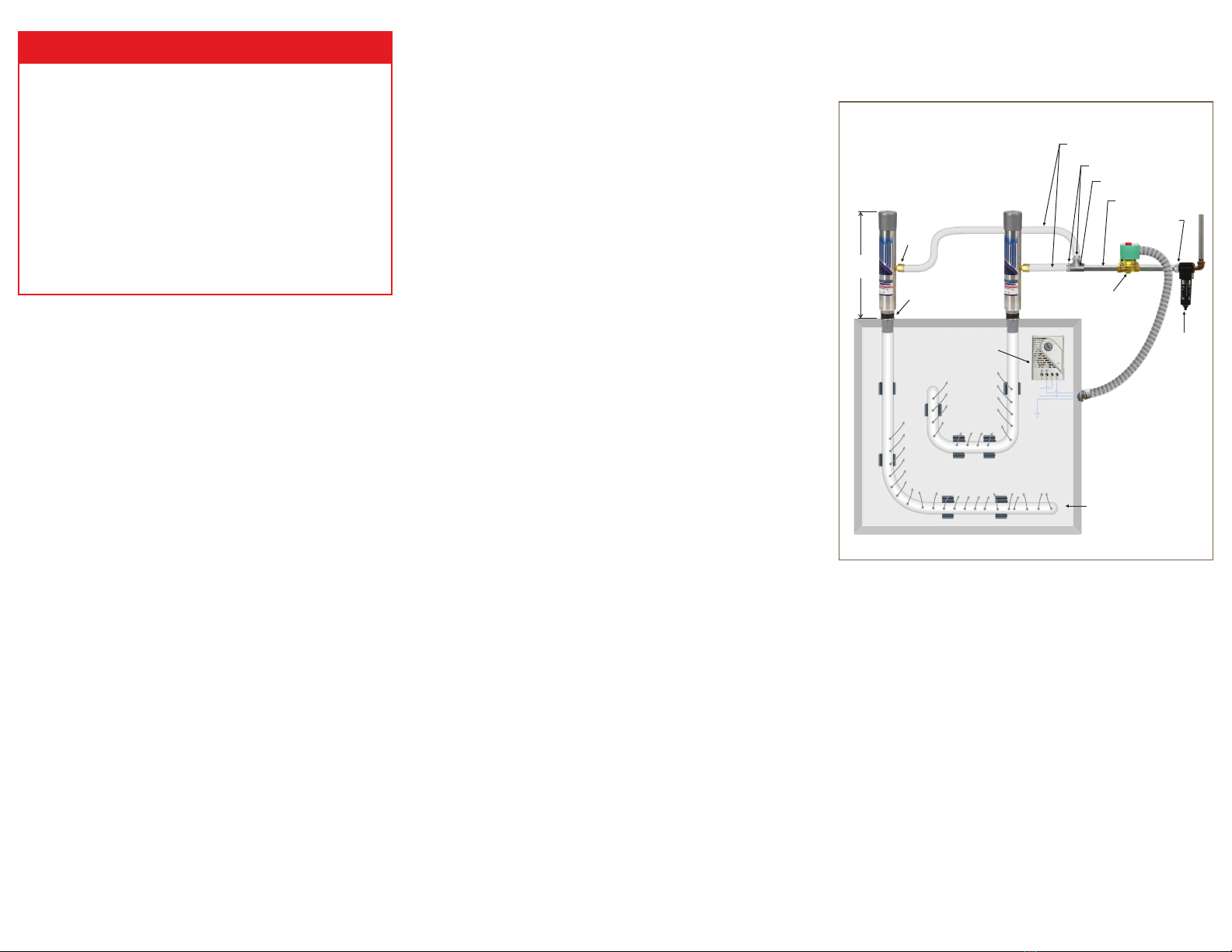

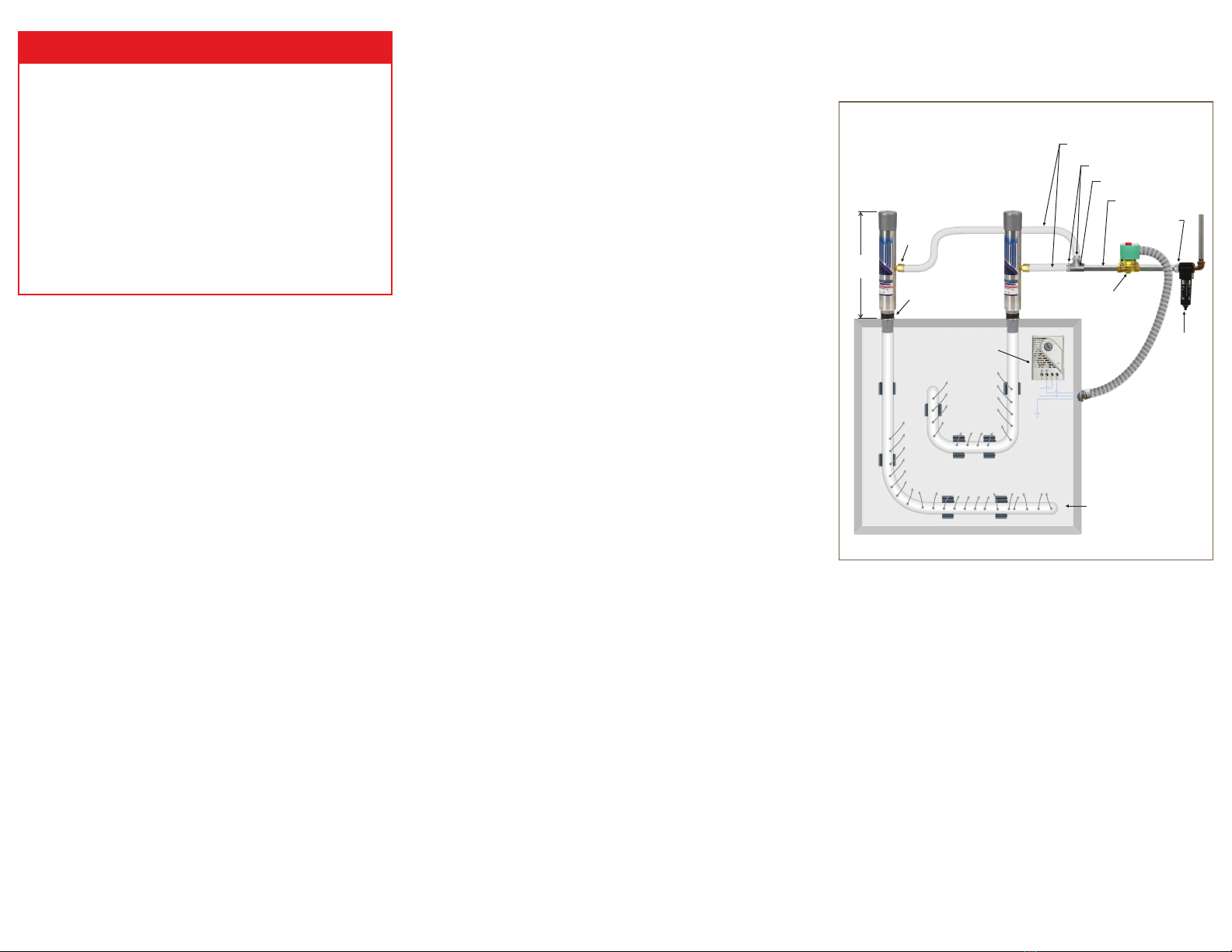

inStaLLatiOn and OperatiOn

For best results, Type 12 Vortex Coolers should be installed

in a vertical orientation on a at horizontal surface at the

top of the cabinet, or in a horizontal orientation on a at

vertical surface on the side of the cabinet.

Vents in the cabinets must be covered and sealed to

ensure cooling efficiency and to keep out ambient air.

When a thermostat is supplied with a Vortex Cooler

system for Type 12 enclosures, the thermostat can be

easily readjusted using the temperature indicator dial. All

wiring must be installed in an approved conduit.

Installation procedures:

1. Cut two 1-1/8” (29 mm) (3/4” knockout size) holes in the

enclosure.

2. Insert the Vortex Coolers into the cut-outs and secure

with the locknuts.

3. Perforate the ducting kits with several 1/8” (3 mm) holes

and secure to interior of enclosure.

4. Attach the ducting kits to the cold outlets of the Vortex

Coolers.

5. Connect compressed air lter and/or valve and

thermostat, to the Vortex Coolers (wire thermostat

directly to solenoid valve). Pipe ttings are provided

for connecting the compressed air lter, solenoid valve

(in 7970 models) and Vortex Coolers. Additional piping

must be provided by the end user.

6. Connect compressed air supply to the lter.

trOubLeShOOting

Insufficient airow may be caused by the following:

1. Undersized compressed air line size.

2. Compressed air pressure too low.

3. Partial or complete blockage of internal compressed air

path, due to dirt.

Insufficient cold air temperature may be caused by:

1. Compressed air line temperature too high.

2. Water vapor in the compressed air supply.

3. Loose cold cap. This may occur if not tightened properly

after disassembled for cleaning.

If trouble persists, please contact Vortec at 1-800-441-

7475.

LiMited warranty

Vortec compressed air products manufactured by ITW

Air Management will be replaced or repaired if found

to be defective due to manufacture defect within ten

years from the date of invoice. Refer to our website

www.vortec.com for full warranty details and limitations.

ITW Air Management makes no specic warranty

merchantability or warrant of tness to a particular purpose.

1. Do not operate a Vortex Cooler at compressed air

pressures above 150 psig (10.3 Bar).

2. Do not operate at line temperatures above 110oF

(43oC).

3. Avoid direct contact with compressed air.

4. Do not direct compressed air at any person.

5. When using compressed air, wear safety glasses

with side shields.

VOrteX cOOLer aSSeMbLy

(Drawings shown below are not to scale)

Models 7870, 7970

generaL Safety cOnSideratiOnS

warning: cOMpreSSed air cOuLd cauSe

death, bLindneSS Or injury

10-3/4

(273 mm)

1-1/8" Hole

1/4" NPT (F)

1/4" piping or 3/8" inside diameter hose

(keep as short as possible – user supplied)

1/2" pipe nipple (2 supplied)

1/2 x 1/4" pipe reducer (2 supplied)

3/4" x 1/2" pipe

reducer (supplied)

Solenoid NEMA 12

110v / 60 Hz

Air Filter

Ducting Kit

Cold Air

Line

Neutral

Ground

Thermostat

Cold Air

1/2" Tee