9025 USER’S MANUAL: SECTION 3 VIRGINIA PANEL CORPORATION

10/4/13

3-2 For more information visit vpc.com

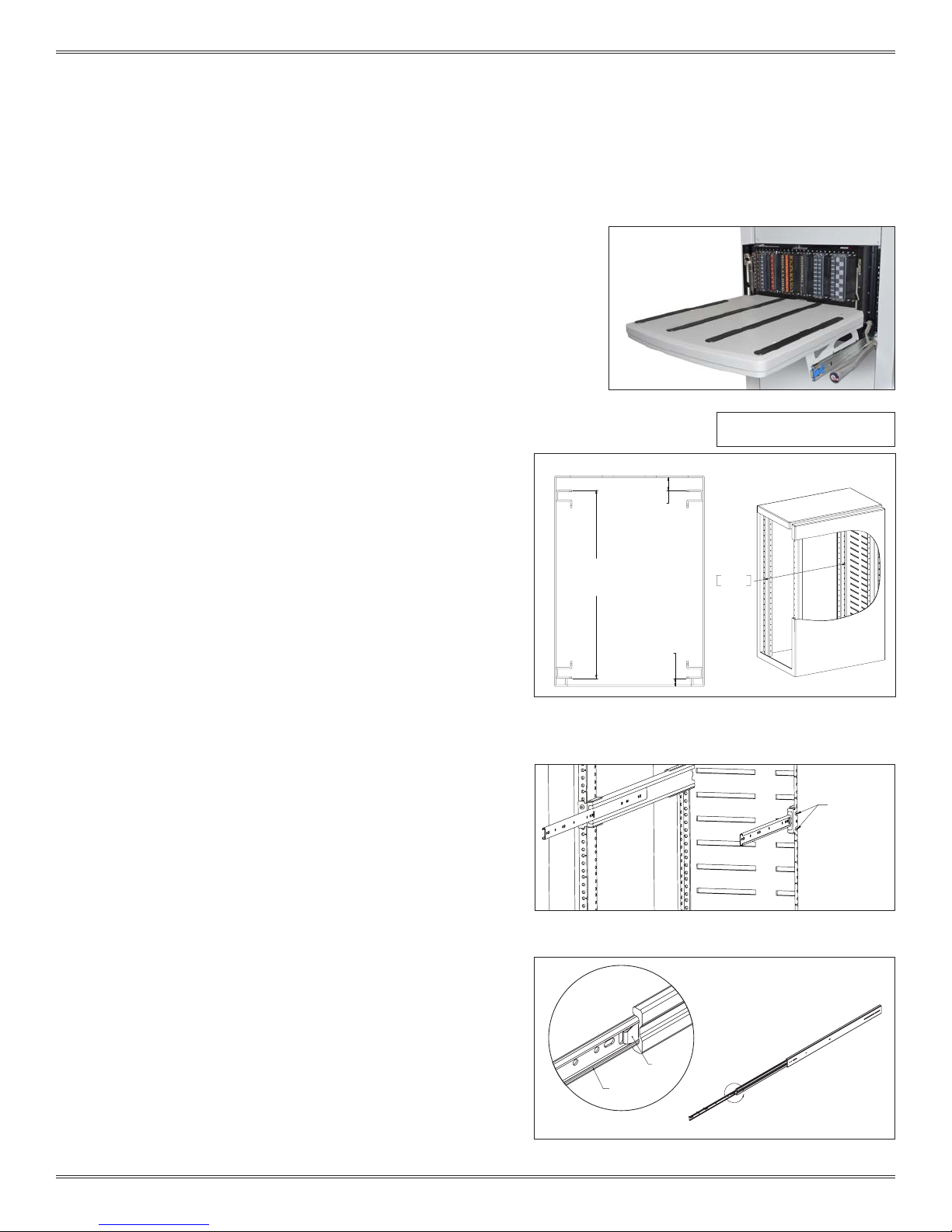

ALWAYS SUPPORT THE RECEIVER AND PLATFORM

WITH THE MOST ROBUST (MIDDLE) SECTION OF

THE SLIDES.

To ensure proper support when extending the receiver and

table away from the rack, stop the receiver and platform at

approximately 6" from the rack. Reach around to the rear of the

receiver to the slides underneath on both sides. Manually extend

the middle section of the slides forward until fully underneath

the platform. The receiver and platform may then be extended

while holding this middle slide in place. If completed properly,

the middle section of the slides will remain underneath the

platform and offer the strongest support.

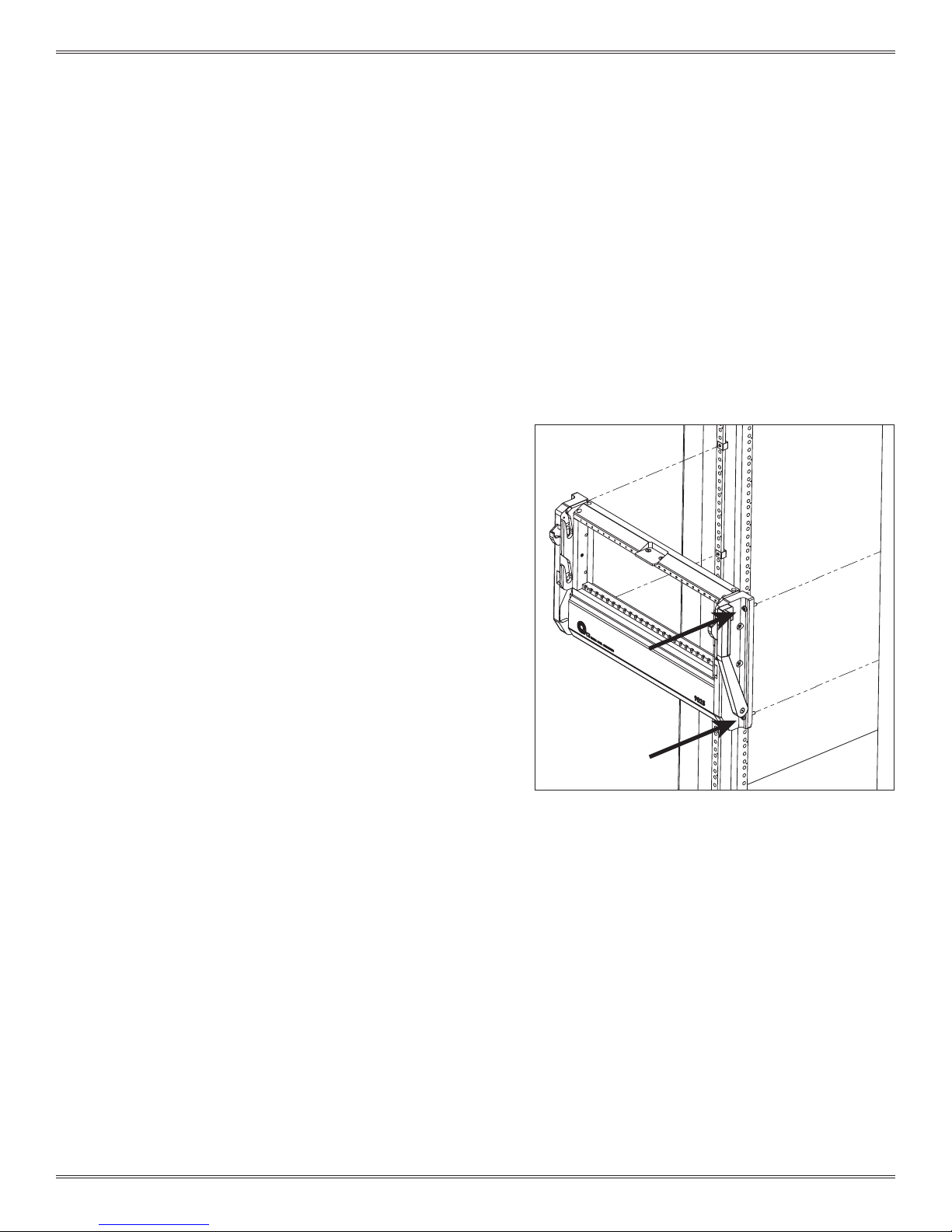

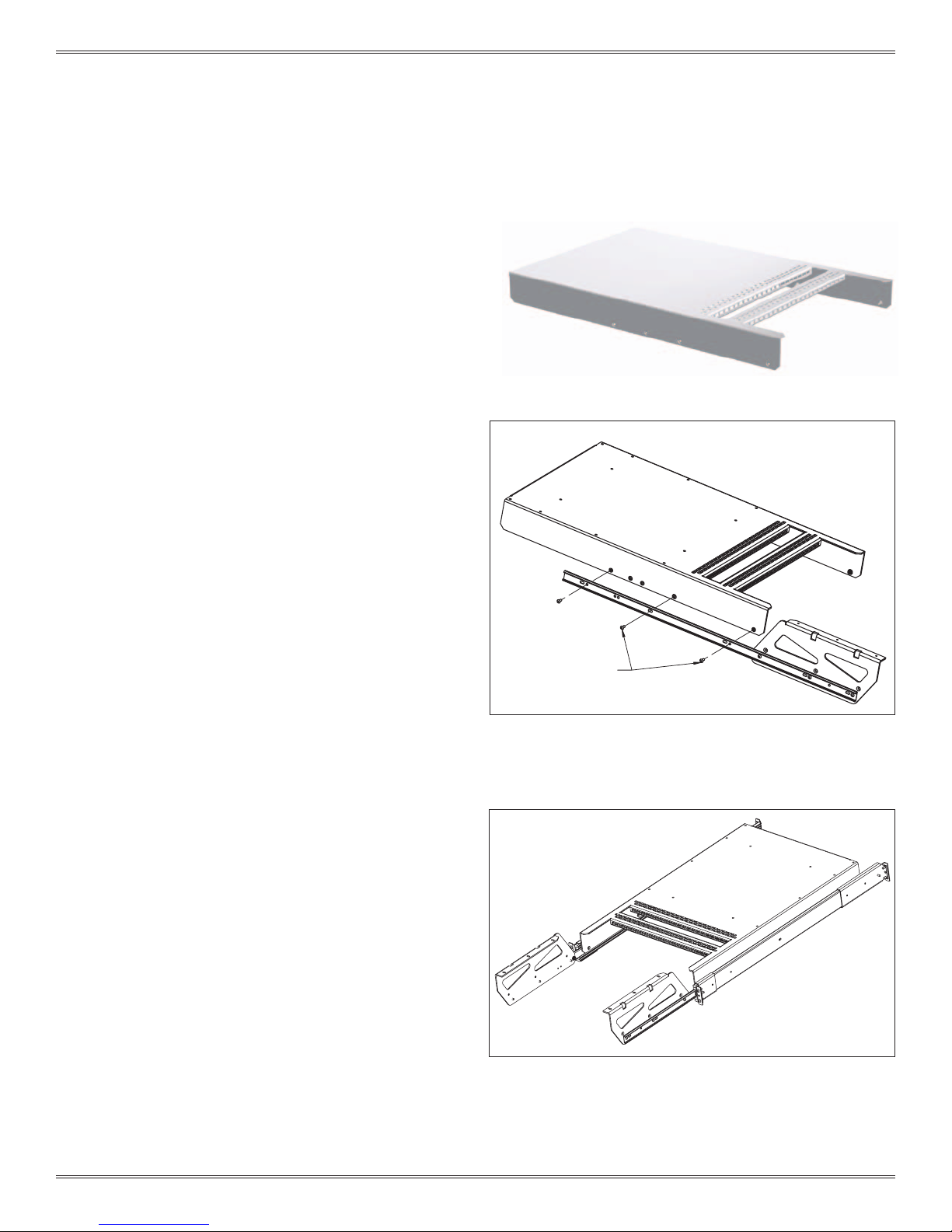

INSTALLATION - 9025TR

1. Install inner slides back into slide kit in the rack.

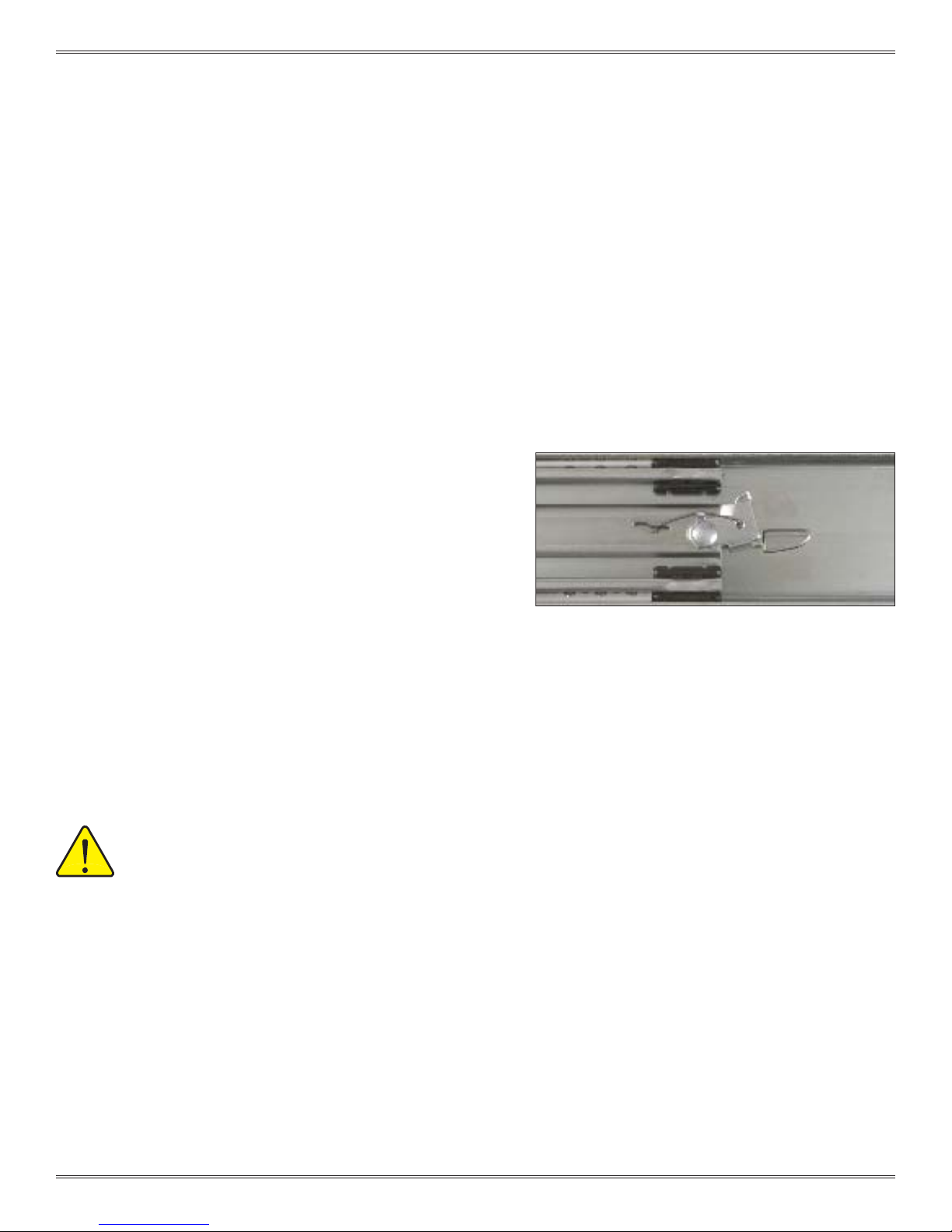

2. Attach the platform mounting anges to the inner slide rails

using the six 8-32 button head screws provided with the

receiver (Figure D). Do not fully tighten down the screws.

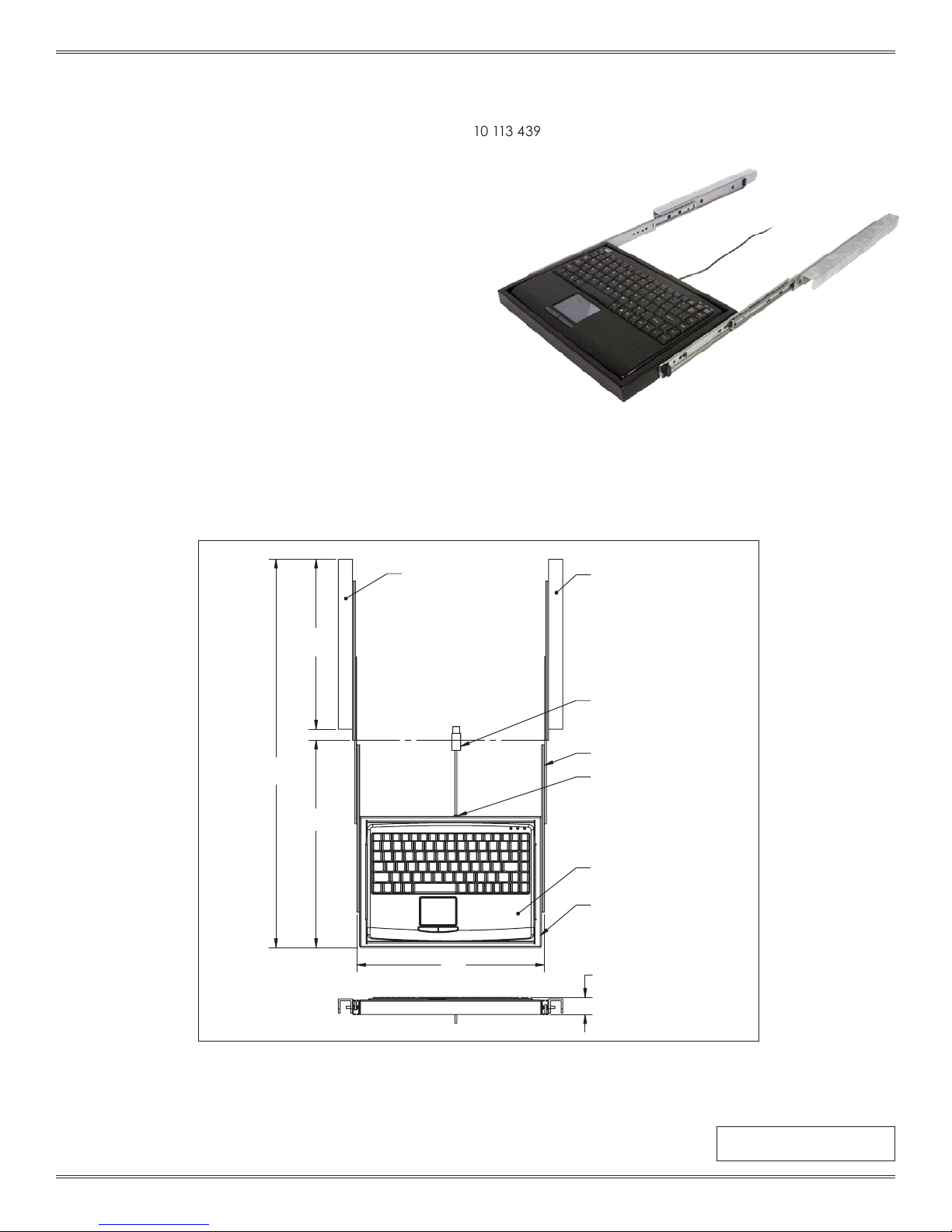

3. Install the 9025TR platform/receiver onto the platform

mounting anges with the six 8-32 screws (Figure E). Do not

fully tighten down the screws.

4. Pull the receiver out as far as possible. The slides will lock in

position. Push the blue tabs located on the middle section

of the slides. Apply pressure to push the receiver back in

toward the rack. The smaller inner slides move into the

middle section, which should not move. Push receiver until

it backs into the rack.

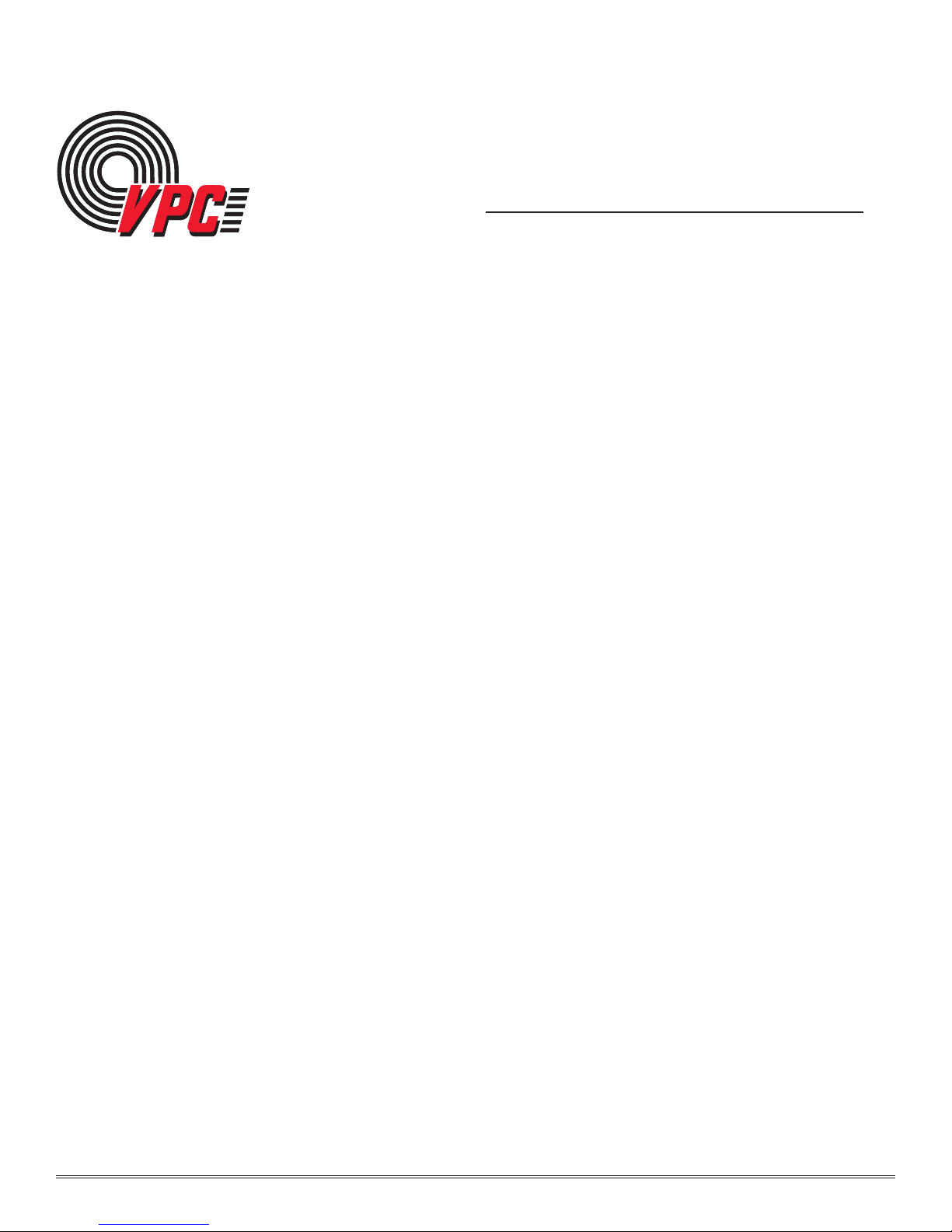

5. Secure the receiver to the rack using the captive 10-32

screws (Figure F). Be sure to lift up on the platform slightly to

ensure an even engagement of the screws.

6. Fully tighten screws in this order:

- 6 8-32 platform mounting screws (as shown in Figure D).

- 6 8-32 button head platform mounting ange screws (as

shown in Figure C).

- 4 front slide mounting screws (from Slide Mounting

procedure, previous page).

- 4 rear slide mounting screws (from Slide Mounting

procedure, previous page).

7. Unscrew the 10-32 captive screws and slide the receiver

out.

9025TR RECEIVER 9025TR PLATFORM

8-32 X .62"

FLAT HEAD SOCKET SCREW

TYP. 6 PLCS.

CAPTIVE 10-32

PANHEAD SCREWS

TYP. EACH SIDE

Figure E. Install 9025TR into platform mounting anges.

Figure D. Attach platform mounting anges to the inner slide

rails.

Figure F. Secure the receiver to the rack with the captive 10-32

screws, taking care to lift up on the platform slightly to ensure

even engagement.

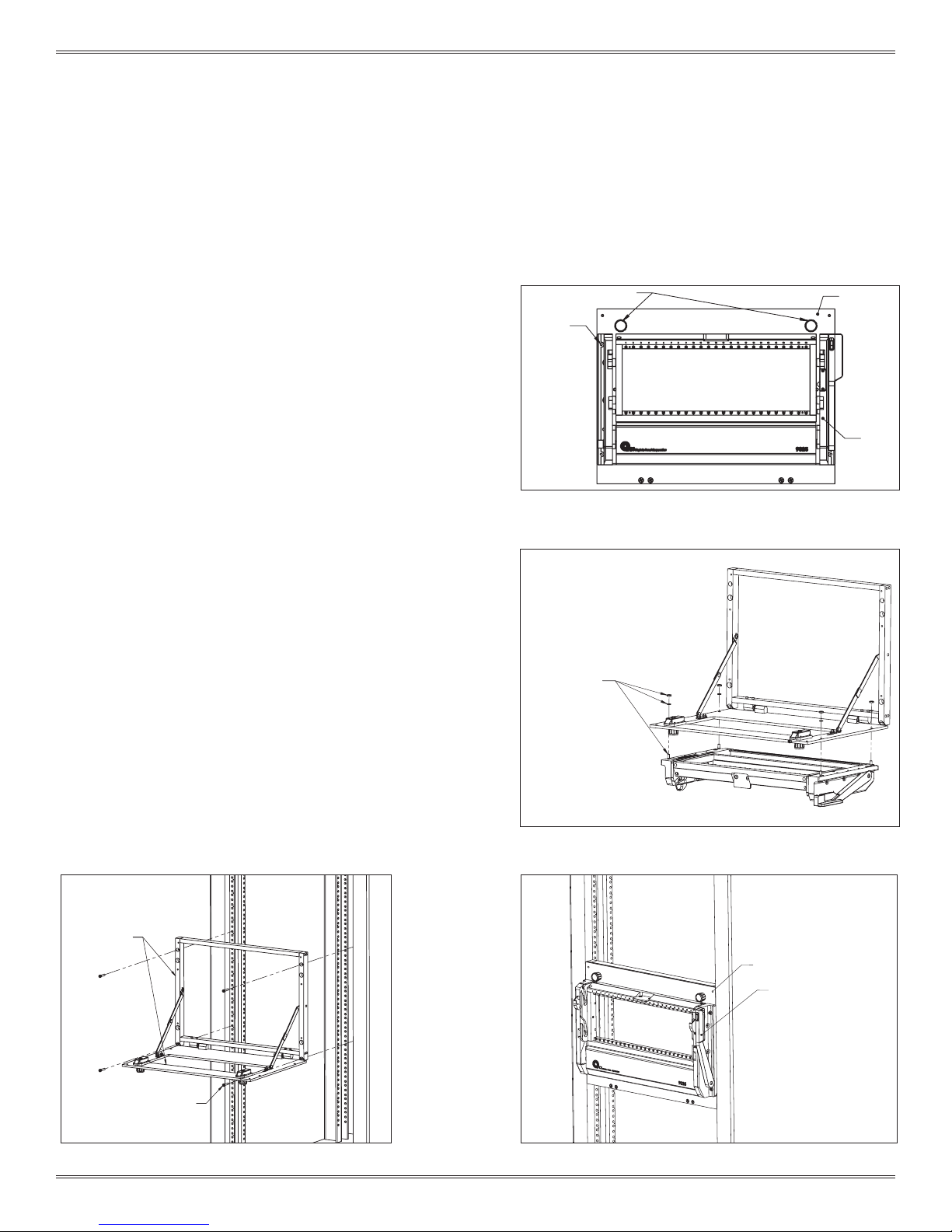

SLIDE CONFIGURATION INSTALLATION - 9025TR

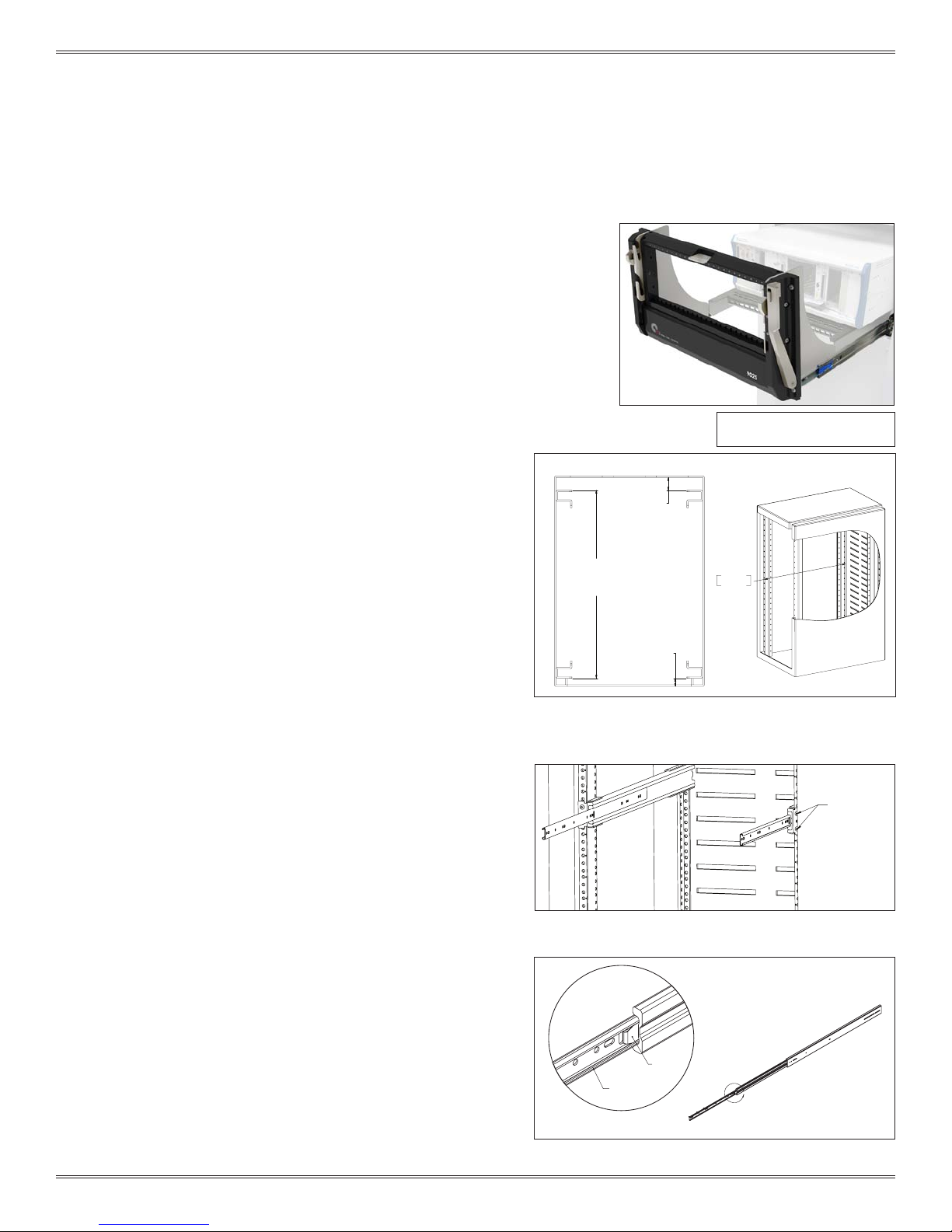

RECEIVER, 9025TR, 25 MODULE, WITH 20" PLATFORM • PART # 310 104 435

28" SLIDE KIT (FITS 26"– 30" DEEP RACKS [660.4 – 762]) • PART # 310 113 451

30"SLIDE KIT (FITS 28"– 32" DEEP RACKS [711.2 – 812.8]) • PART # 310 113 411

36"SLIDE KIT (FITS 34"– 38" DEEP RACKS [863.6 – 965.2]) • PART # 310 113 500