OSBBF20A-EN

6/14

ELECTRIC ACTUATOR SPECIFICATIONS

3 way valve: SHUT / Position , OPEN / Position

AD2 HD2 type

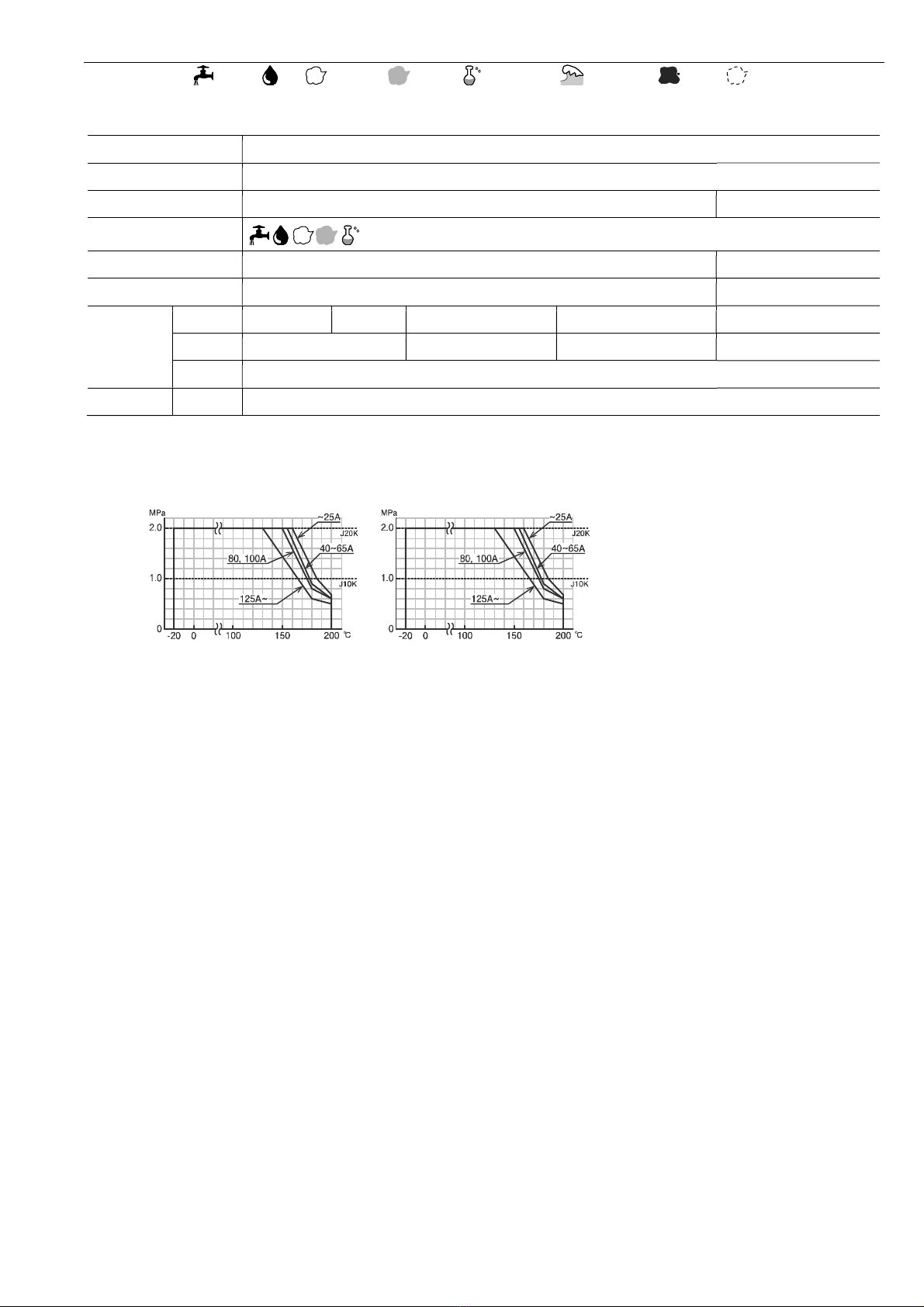

Actuator type ( :Voltage code) AD2-300- AD2-700- HD2-300- HD2-700- HD2-02K- HD2-06K-

Voltage 100 / 110 V AC ±10 % 50/60 Hz (Code: 1)

200 / 220 V AC ±10 % 50/60 Hz (Code: 2)

24 V DC (Code: 0)

Rated torque [Nm] 30 70 30 70 200 600

Operation time [s] 3 to 4 6 to 10 1 to 2 3 to 5 AC: 8 to 15

DC: 12 to 17

AC: 24 to 45

DC: 36 to 50

Power consumption (Max) [VA] AC: 100

DC: 80

AC: 150

DC: 120

Motor DC motor

Overload protection Current limiter

Method of operation a-contactinput type, with built-in relay

Operation SW is OFF SHUT (R3 SW is ON)

SW is ON OPEN (R4 SW is ON)

Over torque R5 SW is ON

Input signal current 10 mA 100 V AC / 6.5 mA 200 V AC / 38 mA 24 V DC

(Leakage current in SW: less than 1 mA) *O terminal input: Photo coupler

Output signal rating Resistance load 0.5 A 125 V AC / 1 A 24 V DC Micro load 1 mA 5 V DC

Alarm signal Output when the motor protection circuit operates by the overload.

(it returns by power supply OFF or reverse operating signal)

Duty cycle 20 % 15 min. (When ambient temperature is over 50 ºC, 10 % 15 min.)

Ambient temperature -20 to 55 °C

Space heater 0.8 W

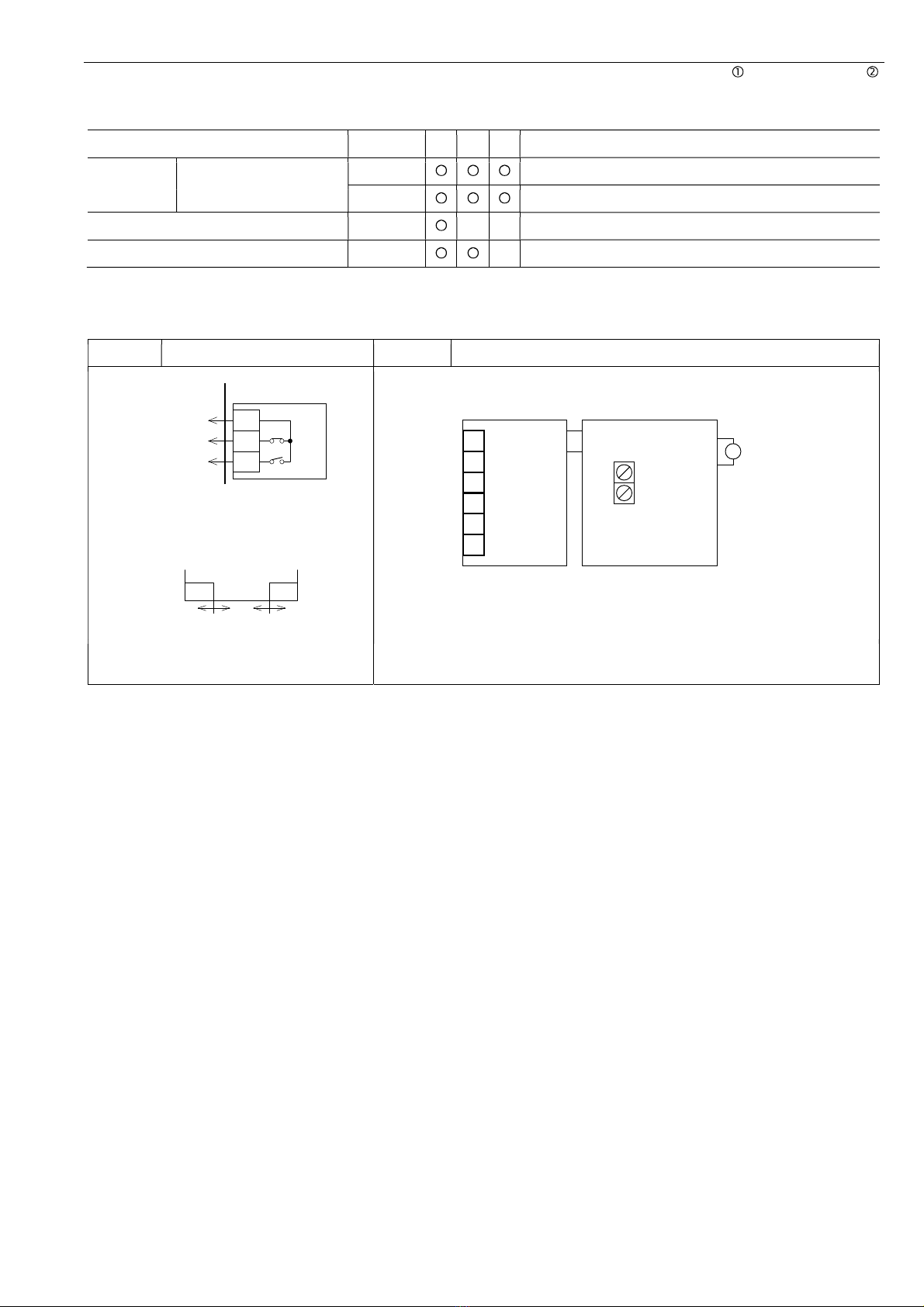

Manual operation Manual over-ride with clutch. (Direct operation / 06K: Operation by manual shaft.)

Enclosure Equivalent to IP65 (IEC 60529)

Housing material Aluminum alloy diecast (acrylic resin baking finish)

Wire connection Terminal Block: M3, Ground terminal: M3

Conduct port 2-G1/2 Attachments: Cable gland (for 6 to 12 mm cable), plug.

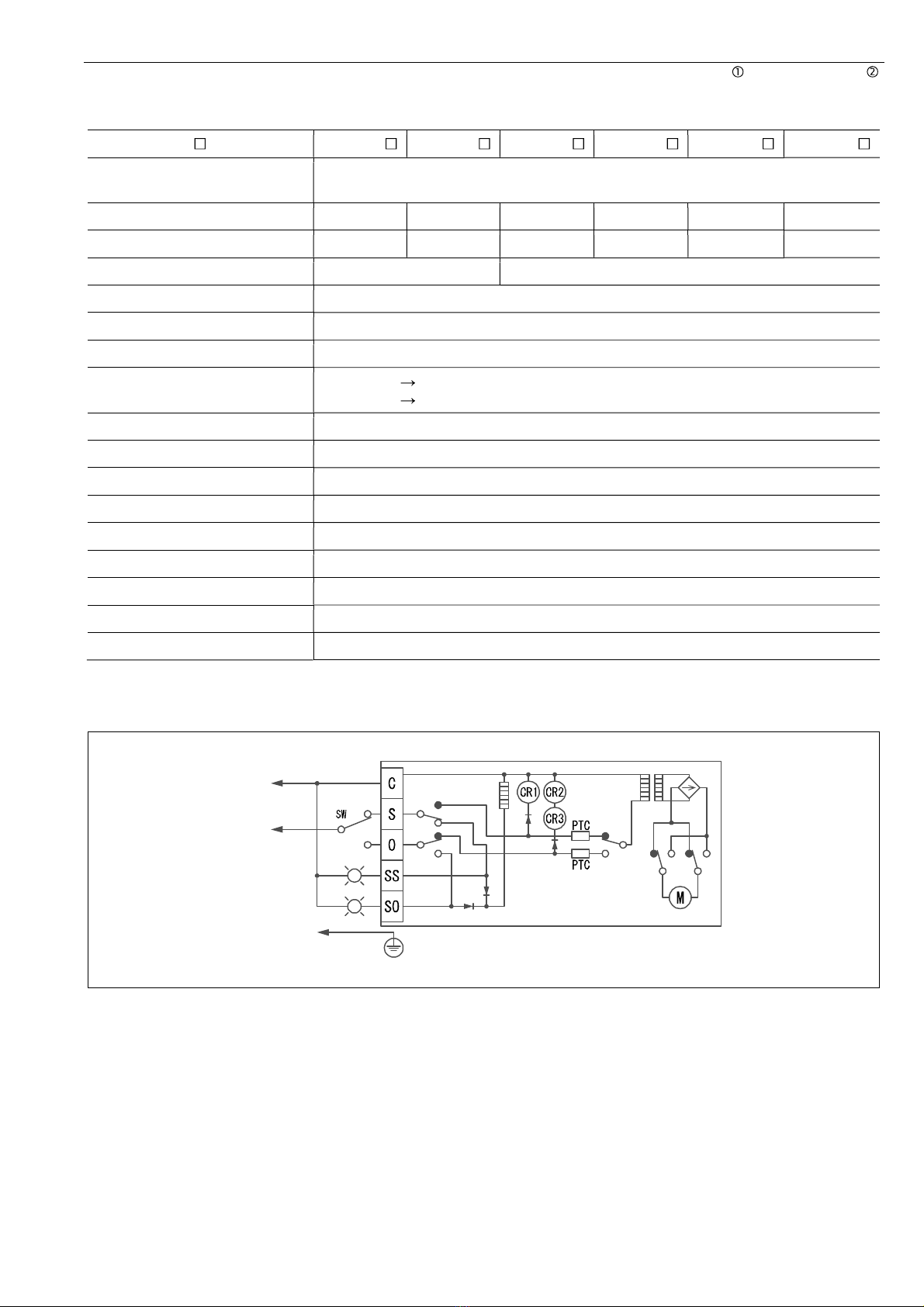

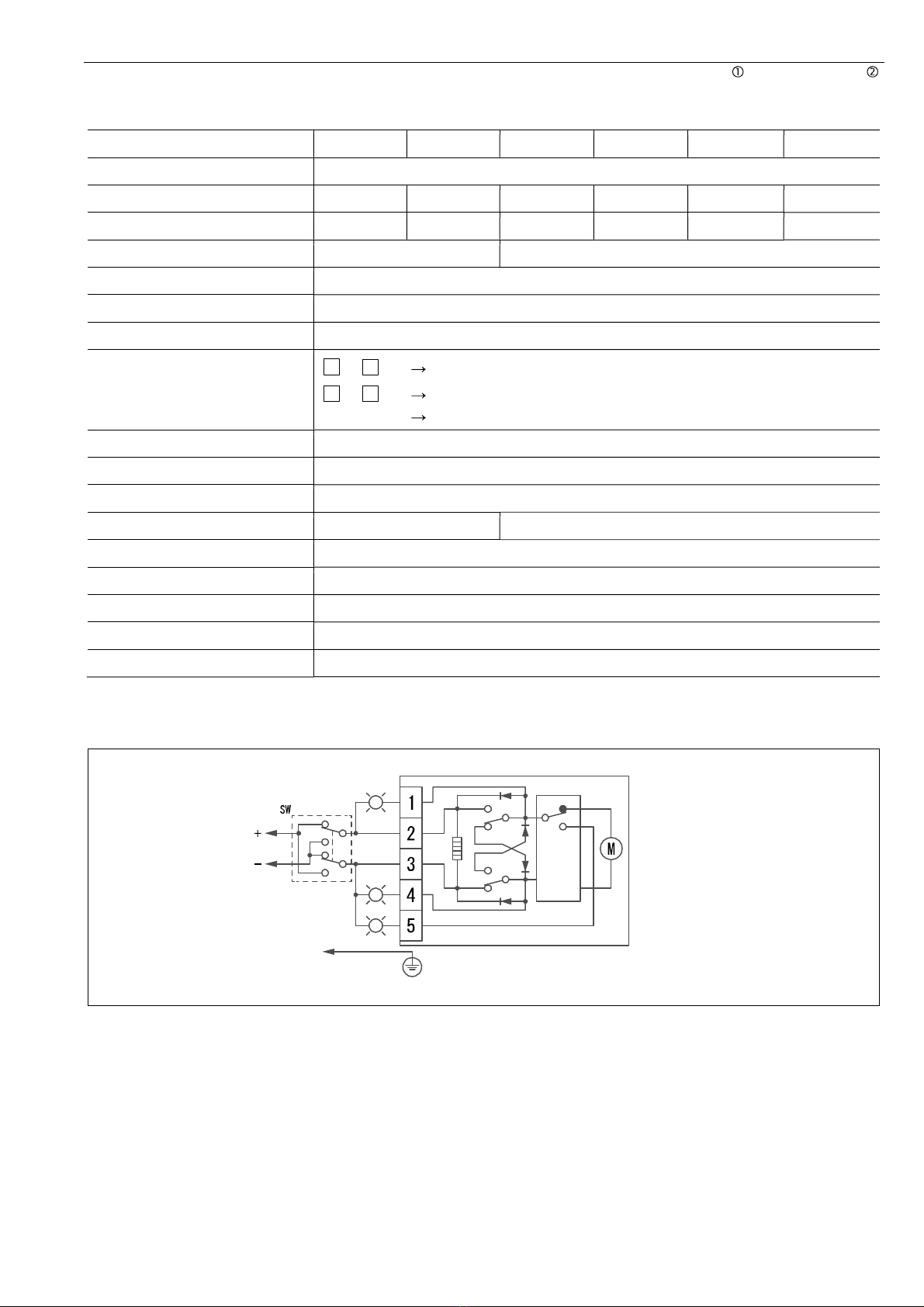

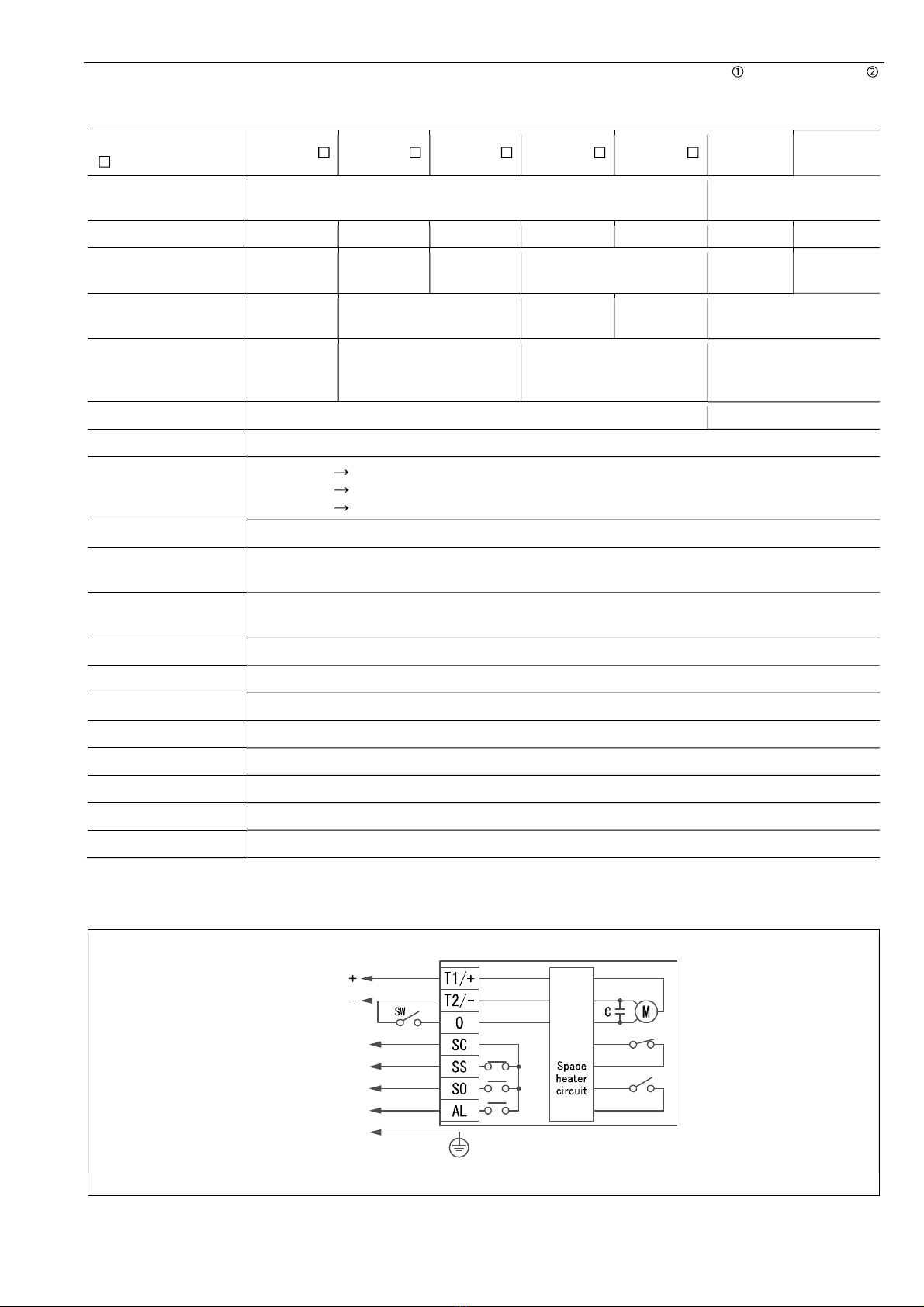

WIRING

Note) Leakage current in SW: less than 1 mA.

SH

(T)ACpoweronly

R3

R4

R5

SH

R1

R2

S.LS O.LS

com.

Voltage

100/110V AC

200/220V AC

24V DC

SHUT signal

OPEN signal

Alarm signal

Ground terminal(M3)