OSVBF225-EN

9/11

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

HANDLING & STORAGE

HANDLING

Proper care in handling the valve should be taken to

prevent damage. Do not drop or throw it.

STORAGE

Store the valve in the protected area from dust,

moisture, and direct sunlight. If possible, should be

kept in the original packaging.

CHECKING

• Check the product code, power supply, and voltage

before installation.

• Make sure that the bolts are not loose.

• The DIP switch should be set up before the power is

turned on. Do not touch unnecessary switches.

INSTALLATION

PRECAUTIONS

• Flush the pipeline carefully before installing the

valve. Foreign particles, such as sand or pieces of

welding electrode, will damage the ball and seats.

• For valves with specified flow direction (V), check the

arrows on the product before piping.

• When the flow path is subjected to a high pressure

from arrow, it may leak slightly to the low pressure

port. (L2)

PIPING FLANGES

• Gasket should be selected appropriately to suit the

fluid, pressure and temperature.

Use spring washer to prevent from decreasing

surface pressure gasket when the temperature

change happens frequently.

• Tighten all bolts using crossover method to load the

joint evenly.

ENVIRONMENT

• Do not install in place where corrosive gas is present

or where vibration is heavy (0.5 G or more).

• When radiant heat causes the surface temperature

of the control unit to exceed 55 °C, provide an

appropriate shielding plate.

• If there is a possibility that the fluid and drive part

freeze, please take measures to prevent freezing.

POSITIONING

Should be positioned through 90° upward from

horizontal. Provide space around the product to

allow manual operation, inspection and replacement

work.

Maintenance space for upper part of actuator.

AEX (120 / 360 / 700) More than 105 mm

AEX (02K / 06K) More than 120 mm

OTHER NOTES

Until the wiring is completed there must be no

condensation or flooding in the interior of the

actuator, after piping. Protective caps on the cable

gland are not waterproof.

TIGHTEN THE GLAND NUTS

• Check that there is no leakage from the gland

packing.

• If it leakage, tighten gland nuts by alternately.

Do not over-tighten the gland nuts.

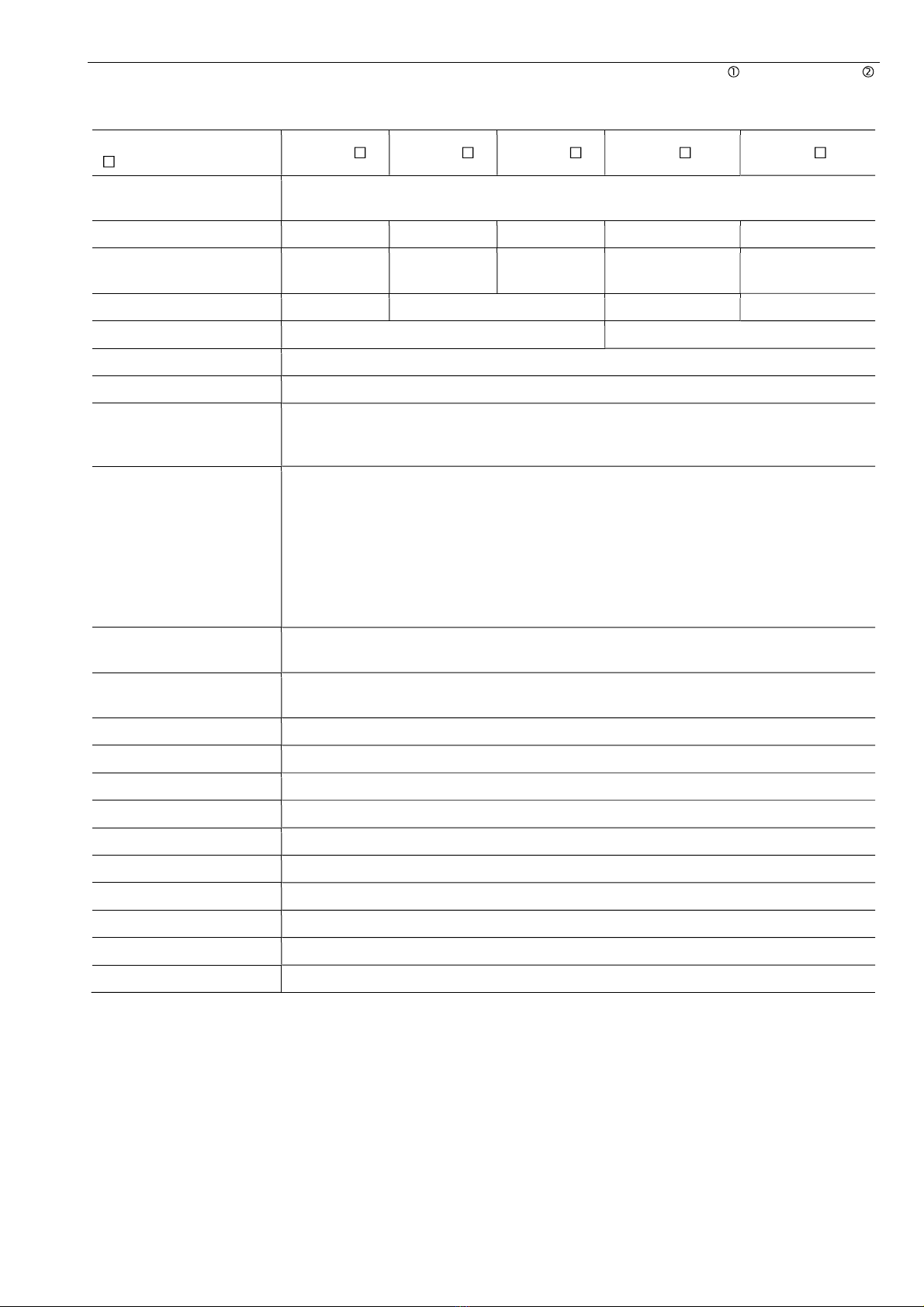

Recommended torques

Valve size [mm] Torque

[Nm]

BF V L2

015

020

025

025 020

025 6

040

050

040

050

040

050 9

065

080

100

065

080

100

065

080

100

15

125

150

125

150 - 25

- 200 - 30

WIRING

PRECAUTIONS

• Remove the actuator cover before wiring.

• Two G1/2 electrical connections are provided with a

cable gland and plug. Usable cable size is 6 to 12

mm.

• When using a flexible tube, dew condensation may

occur inside the actuator due to respiration from the

inside of the tube and malfunction may result. Seal

the flexible tube connector part with a sealant.

• Sealants that affect the electrical contacts should not

be used inside the electric actuator.

• If long distance wiring or low voltage operation,

check that terminal voltage is in the proper range.

• Input signal circuit is non-isolated.

Do not connect DC (minus) wire to other DC (minus)

common.

CONNECTION

• Do not wiring outdoors on a rainy day.

• Check the power supply and voltage.

Connect the signal as shown in the wiring diagram.

Do not connect unnecessarily terminal.

• Check whether the MODE change DIP SW on a

circuit board substrate is set up correctly.

• When wiring, if wiring of a signal is mistaken, it will

not operate correctly. Contact us when you use two

valve or more by one controller or indicator.

• Actuator should be electrically grounded.

Use the terminal marked ( ) inside the actuator.

Gland nut

Gland plate Stem