OSPDN225-EN

6/8

INSTALLATION, OPERATION & MAINTENANCE INSTRUCTIONS

HANDLING & STORAGE

HANDLING

Do not drop or throw the product as it may break.

STORAGE

• Store away from dust, moisture and direct sunlight.

If possible, store in the original package.

• Do not remove a dust proof cap until the piping.

CHECKING

• Check the product code before installation.

• Make sure that the bolts are not loose.

INSTALLATION

PRECAUTIONS

• Flush the pipeline carefully before installing the

valve. Foreign particles, such as sand or pieces of

welding electrode, will damage the disk and seats.

• For valves with specified flow direction (DN), check

the arrows on the product before piping.

• Valve is shipped closed. (TAC is closed with a

manual unit. Without a manual is open.)

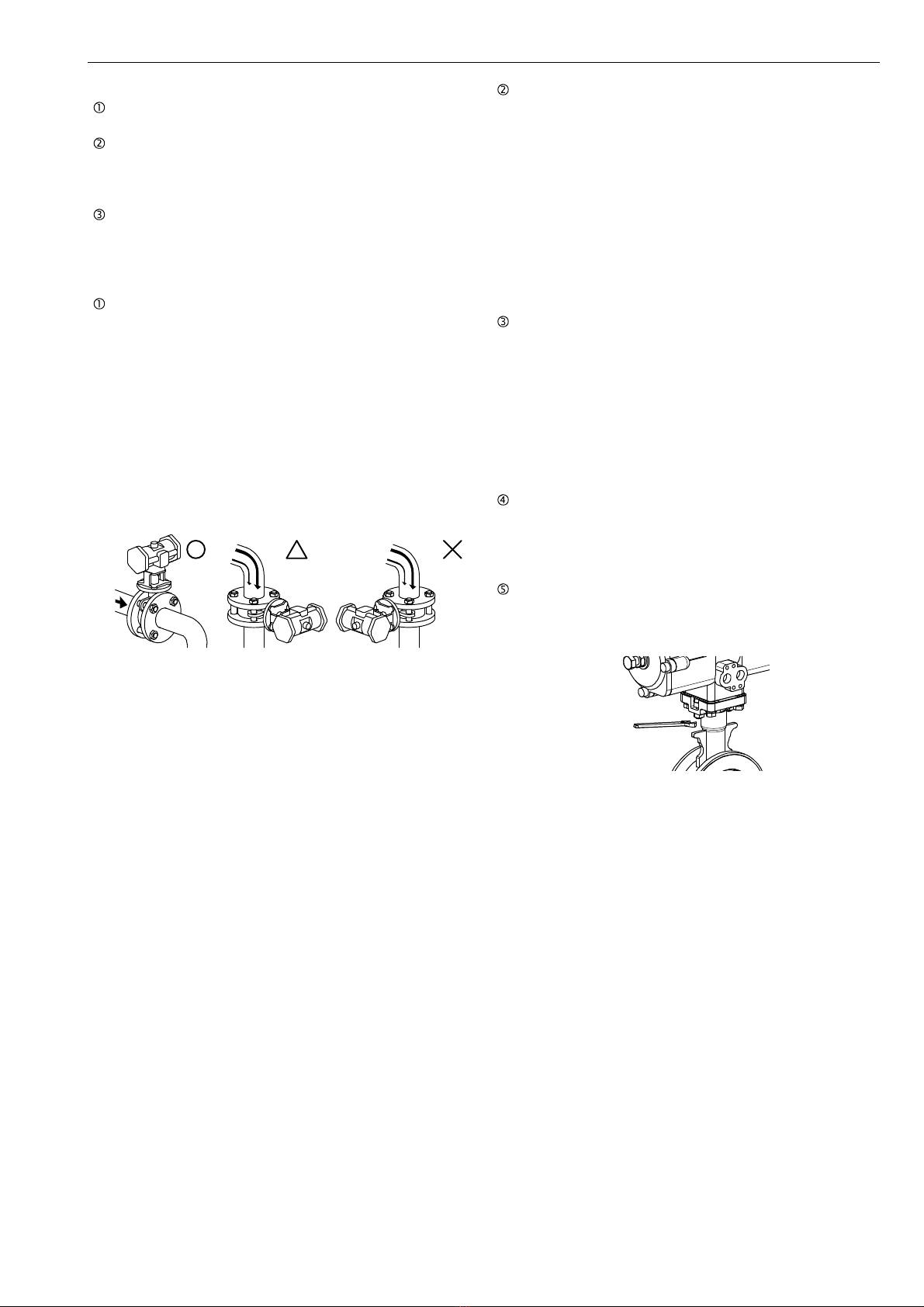

• The butterfly valve should be piped upstream of the

elbow. When piping downstream from the elbow,

considered a straight line that is at least five times

the length of the pipe.

• The valve stem should be mounted perpendicular to

the flow for biased fluid.

• Disc interference may also occur when valve is

installed in pipeline with smaller than normal inside

diameter such as thick wall pipe, or lining pipe.

Suitable corrective measurement must be taken

(taper boring the pipe or pipe liner, etc.)

PIPING FLANGES

• Gasket should be selected appropriately to suit the

fluid, pressure and temperature.

Use spring washer to prevent from decreasing

surface pressure gasket when the temperature

change happens frequently.

• Wafer type butterfly valve is put between two seats

of flanged-end and tightened with long bolts.

• Before bolts are tightened, valve should be centered

within the bolts to prevent possible disc interference

or damage by contact with the pipe or flange.

• Tighten all bolts using crossover method to load the

joint evenly.

ENVIRONMENT

• Do not install in place where corrosive gas is present

or where vibration is heavy (0.5 G or more).

• When radiant heat causes the surface temperature

of the control unit to exceed 50 °C, provide an

appropriate shielding plate.

• If there is a possibility that the fluid and drive part

freeze, please take measures to prevent freezing.

• For single-acting type, prevent water and dust from

coming into air exit.

POSITIONING

Should be positioned through 90° upward from

horizontal. Provide space around the product to

allow manual operation, inspection and replacement

work.

CAUTIONS FOR MAINTENANCE

Do not keep warm for maintenance of the valve

gland.

Fast

Slow Fast

Slow