Installation:

ATTENTION:

Personal injury, damage, or explosion due to leakage of accumulated gas, or rupture of pressurized

components could result if this pilot is overpressured or is installed where operating parameters could exceed

the design limits as indicated in this manual, or where parameters exceed the ratings of the regulator body,

adjacent piping or piping components & fittings. Verify the pressure limitations of pilot and the regulator on

which it is installed to ensure neither device is overpressured. To avoid injury or damage to property, incorporate relief

valves or pressure limiting devices to prevent operating parameters from exceeding required limits. Reference U.S. code

of Federal Regulations, by the National Fire Codes of the National Fire Protection Association, or by other applicable

codes or codes mandated by the operating company as needed.

WARNING

Regulator Pilots and Pilot Operated Regulators installed in enclosed or confined spaces should be provided

with adequate ventilation to prevent the potential of gas accumulation from leakage or venting. Leakage and

vent gas can accumulate causing property damage, severe injury or death. Atmospheric vent ports should be

vented to a safe area away from air intakes, or any hazardous location.

PERSONNEL: Installation of RP Series Regulator Pilots and other manufacture’s Pilot Operated Regulator

Bodies should be performed by qualified personnel that are familiar with high pressure natural gas piping and regulator

technologies.

INSPECTION: Inspect the RP Series Pilot for damage that might have occurred in shipping and handling. Do NOT use

any product that has any remote semblance of damage. Care should also be taken to ensure that no damage exists on

previously installed products that may have been installed at previous locations. If the origin or operational capability of

any product is suspect or unknown, we recommend confirmation of fitness for service by a qualified technician or by VRG

Controls.

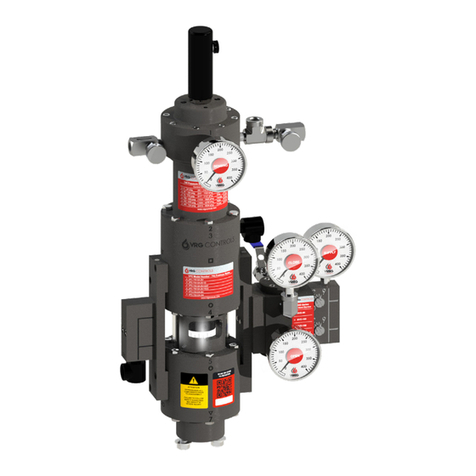

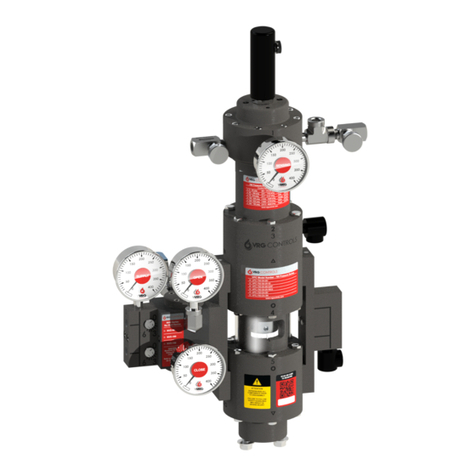

ACTION: Inspect the RP Model Number Identification Label AND the Body of the RP Series Pilot to ensure that the unit

has the appropriate ACTION for the desired application. Figures XX and Table XX provide necessary information to

confirm RP Series Pilot Action.

INSTALLATION ORIENTATION: RP Series Regulator Pilots may be installed in any orientation. However, for optimum

results and ease of maintenance, it is typically receommended to install RP Series Pilots in a vertical orientation with the

RP Series Setpoint Adjustment Screw pointing upward.

PILOT MOUNTING: The RP Series Pilot may be installed utilizing a convenient mounting bracket available from VRG

Controls. The RP Pilot may be wall mounted or 2.0 in pipe mounted.

PIPING: Appropriate pipe thread seal tape should be applied to all fittings installed on the RP Pilot. Use of pipe dope is

also encouraged to minimize potential for galling or damage to threaded connections. All threaded connection on the RP

Pilot are ¼ in FNPT.

PILOT SUPPLY LINES: 3/8in stainless steel tubing or ¼ in diameter threaded, non-restricted connections should be

utilized to make connections to the RP Series Pilot. The INLET connection should be made with restrictions in the piping

components. In the event that an isolation valve is installed in the INLET connection, it should be a full-opening type

without restriction.

FILTRATION: Most gas pipeline applications do not require a filter on the INLET connection. If the application may

exhibit dirty gas, an appropriate filter should be applied upstream of the INLET connection to prevent clogging of the

ADJUSTABLE ORIFICE. The filter should be application appropriate with adequate capacity with filtration to 10μ.

PILOT DISCHARGE (OUT): 3/8in stainless steel tubing or ¼ in diameter threaded, non-restricted connections should be

utilized to make connections to the RP Series Pilot. The OUT connection should be made with restrictions in the piping

components. In the event that an isolation valve is installed in the OUT connection, it should be a full-opening type

without restriction.

PILOT GAS PRE-HEATERS: Pilot INLET gas may be heated to prevent excessive refrigeration effects and potential

formation of ice or hydrates in the system. Pilot INLET gas heaters should be connected after the pilot filter upstream of