VRG Controls LLC. 9 of 35 JANUARY 2019

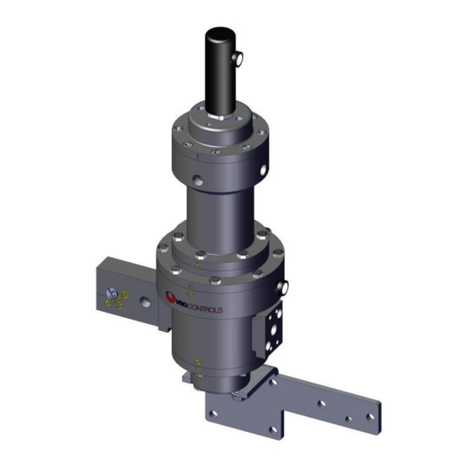

VPC “SN” SERIES VALVE PILOT CONTROLLERS

INSTRUCTION MANUAL

HOW IT WORKS DESCRIPTIONS:

DOUBLE ACTING VPC-DA-SN

When the SENSING pressure is equal to the VPC-DA-SN

setpoint, the net force on the VPC-DA-SN power module is

zero. This is the equilibrium or “balanced” condion where

the sensing pressure that pushes down on the sensing

diaphragm and the control spring force that pulls up on the

sensing diaphragm are equal. When the VPC-DA-SN achieves

equilibrium, the OPEN seat & nozzle assembly and CLOSE

seat & nozzle assembly will be posioned at equal openings

maintaining a constant OUTPUT pressure to the top and

boom chambers of the control valve actuator. The VPC-DA-

SN will exhibit constant emissions at this state as referenced in

Table 1.0. From this posion two possible scenarios can occur,

the sensing pressure can rise above or below the set point.

If the sensing pressure rises above the VPC-DA-SN setpoint

the net force on the VPC-DA-SN power module is downward.

The CLOSE seat & nozzle assembly will move toward closed

posion and divert pressure to the CLOSE chamber of the

double acng actuator. The OPEN seat & nozzle assembly will

open more and pressure shall be reduced on the OPEN side of

the double acng actuator. The combinaon of these acons

creates a dierenal pressure to be applied to the double

acng actuator that will move the valve toward the closed

posion.

If the sensing pressure falls below the VPC-DA-SN setpoint

the net force on the VPC-DA-SN power module is upward.

The OPEN seat & nozzle assembly will move toward closed

posion and divert pressure to the OPEN chamber of the

double acng actuator. The CLOSE seat & nozzle assembly

will open more and pressure shall be reduced on the CLOSE

side of the double acng actuator. The combinaon of these

acons creates a dierenal pressure to be applied to the

double acng actuator that will move the valve toward the

open posion.

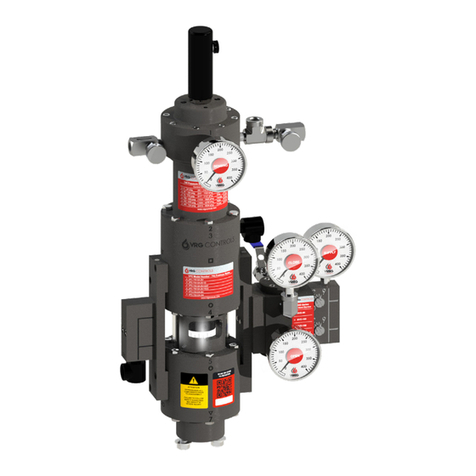

An adjustment for sensivity is achieved via a rotang drum

at the center of the VPC-DA-SN. Rotaon of the drum to the

LEFT (Increasing Numbers) will increase the xed distance of

the internal assembly, requiring greater travel of VPC-DA-SN

internals to aect a change in CLOSE PRESSURE and OPEN

PRESSURE. Conversely, rotaon of the drum to the RIGHT

(Decreasing Numbers) will decrease the xed distance of

the internal assembly, requiring lesser travel of VPC-DA-SN

internals to aect a change in CLOSE PRESSURE and OPEN

PRESSURE.

Adjustable orices are installed upstream of the SUPPLY

PRESSURE that aect the maximum achievable ow rate to

CLOSE PRESSURE and OPEN PRESSURE independently. These

Adjustable Orices may be ulized to adjust the CLOSING and

OPENING speed of travel of the control valve actuator with

both Adjustable Orices being set equally. Alternavely, the

Adjustable Orices may be set at dierent levels to achieve a

dierence between CLOSING and OPENING speed necessary

to opmize control performance for certain applicaons.

Note that the VPC-DA-SN atmospheric emissions may be

completely eliminated by discharging exhaust to a nearby

or downstream pressure system. Addionally, addion of

an NVD No-Vent Device will eliminate emissions when the

control valve remains in the full-open or full-closed posions

such as a standby, overpressure monitor or relief type

applicaon.