VRG Controls LLC. 9 of 54 APRIL 21, 2019

VPC “BV” SERIES VALVE PILOT CONTROLLERS

INSTRUCTION MANUAL

HOW IT WORKS DESCRIPTIONS:

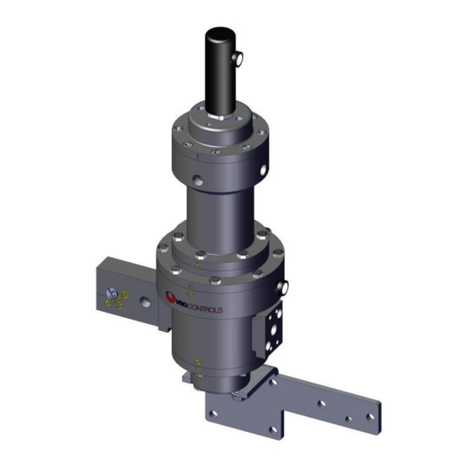

DIRECT ACTING VPC-SA-BV

When the SENSING pressure is equal to the VPC setpoint, the net

force on the VPC power module is zero. This is the equilibrium

or “balanced” condion where the sensing pressure that pushes

down on the sensing diaphragm and the control spring force

that pulls up on the sensing diaphragm are equal. When the VPC

achieves equilibrium, the SUPPLY balanced valve and EXHAUST

balanced valve assemblies will remain closed maintaining a

constant OUTPUT pressure to the control valve. The VPC will

exhibit ZERO emissions at this state. From this posion two

possible scenarios can occur, the sensing pressure can rise above

or below the set point.

If the sensing pressure rises above the VPC setpoint the net force

on the VPC power module is downward. The EXHAUST balance

valve will close. The SUPPLY balance valve opens, increasing the

ow of SUPPLY gas to the OUTPUT port. The combinaon of these

acons creates a rise in output pressure. If the sensing pressure

falls below the VPC setpoint the net force on the VPC power

module is upward. Now the SUPPLY balanced valve will close.

The EXHAUST balanced valve opens, increasing the ow of gas to

the EXHAUST port. The combinaon of these acons decreases

the OUTPUT pressure. In order to control how much gas passes

through the balanced valve, adjustable orices are installed to

restrict the ow via the SUPPLY and the EXHAUST.

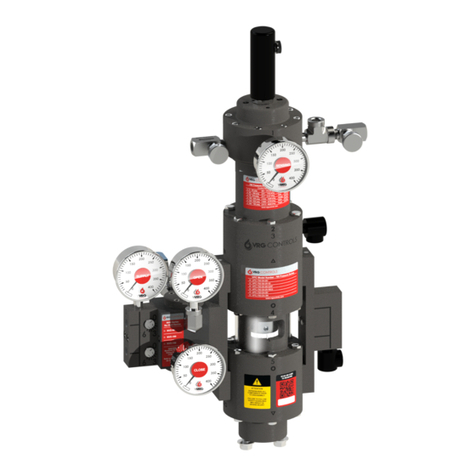

DIRECT ACTING VPC-SA-BV-ID

The VPC is inherently an INTEGRAL funcon device. A DERIVATIVE

funcon may be added to the OUTPUT of the VPC by incorporang

a VOLUME TANK in conjuncon with an adjustable orice on the

OUTPUT signal. The DERIVATIVE component aects the rate at

which the OUTPUT signal change is applied to the control valve

unit. If the DERIVATIVE orice number is increased this will cause a

slower resultant change in OUTPUT pressure (signal) to the control

valve. Conversely, if the DERIVATIVE orice number is decreased

it will permit a more rapid change in OUTPUT pressure (signal)

to the control valve unit. The DERIVATIVE funcon is typically

incorporated to introduce addional stability when the VPC is

applied in conjuncon with a pneumac valve posioner or when

the installed system is has a rapidly aected downstream system

such as a power plant fuel gas feed or two-stage pressure cut

applicaon.

REVERSE ACTING VPC-SA-BV-ID

In this case, the SUPPLY pressure and the EXHAUST pressure are

routed dierently by changing the ORIFICE manifolds. The VPC

will exhibit behavior in a “reverse” scenario. When SENSING

pressure rises above the set point the net force on the VPC power

module pushes downward. The SUPPLY balanced valve will close

and the EXHAUST balanced valve will open, causing gas to vent

through the EXHAUST port. This results in a decrease of OUTPUT

pressure. If the SENSING pressure falls below the VPC setpoint,

the net force on the VPC power module is upward. The SUPPLY

balanced valve will open and the EXHAUST balanced valve will

close causing an increase in OUTPUT pressure. Any VPC “Single

Any VPC “Single Acng” model maybe easily converted

between Direct Acng and Reverse Acng by simply

swapping the posion of the SUPPLY/EXHAUST and OUTPUT

manifolds.

VPC-SA-BV-GAP

For “How it Works” descripon of the VPC-SA-BV-GAP,

reference Direct Acng VPC-SA-BV at top of this page. The

VPC-SA-BV-GAP will dier in construcon by not having

ADJUSTABLE ORIFICES installed. The “GAP Controller”

will dier operaonally as it operates with a “snap acng”

or “on-o” logic. The “on-o” logic produces a HIGH

SETPOINT and LOW SETPOINT which area separated by a

“BAND.” This “BAND” or dierence between the two (2)

setpoints is achieved by widening the deadband via the

SETPOINT ADJUSTMENT DRUM.

DOUBLE ACTING VPC-DA-BV

When the SENSING pressure is equal to the VPC-DA-BV

setpoint, the net force on the VPC-DA-BV power module is

zero. This is the equilibrium or “balanced” condion where

the sensing pressure that pushes down on the sensing

diaphragm and the control spring force that pulls up on

the sensing diaphragm are equal. When the VPC-DA-BV

achieves equilibrium, the OPEN balanced valve and CLOSE

balanced valve assemblies will remain closed maintaining a

constant OUTPUT pressure to the top and boom chambers

of the control valve actuator.

From this posion two possible scenarios can occur, the

sensing pressure can rise above or below the set point.

If the sensing pressure rises above the VPC-DA-BV

setpoint the net force on the VPC-DA-BV power module is

downward. The OPEN balance valve will open and divert

pressure from the OPEN chamber of the double acng

actuator to EXHAUST. The CLOSE balance valve will remain

closed and full SUPPLY pressure shall connue to be applied

to the CLOSE side of the double acng actuator. The

combinaon of these acons creates a dierenal pressure

to be applied to the double acng actuator that will move

the valve toward the closed posion.

If the sensing pressure falls below the VPC-DA-BV setpoint

the net force on the VPC-DA-BV power module is upward.

The CLOSE balance valve will open and divert pressure

from the CLOSE chamber of the double acng actuator to

EXHAUST. The OPEN balance valve will remain closed and

full SUPPLY pressure shall connue to be applied to the

OPEN side of the double acng actuator. The combinaon

of these acons creates a dierenal pressure to be applied

to the double acng actuator that will move the valve

toward the open posion.

Addion of an NVD No-Vent Device will eliminate emissions

when the control valve remains in the full-open or full-

closed posions such as a standby, overpressure monitor or

relief type applicaon.