1

OVERVIEW

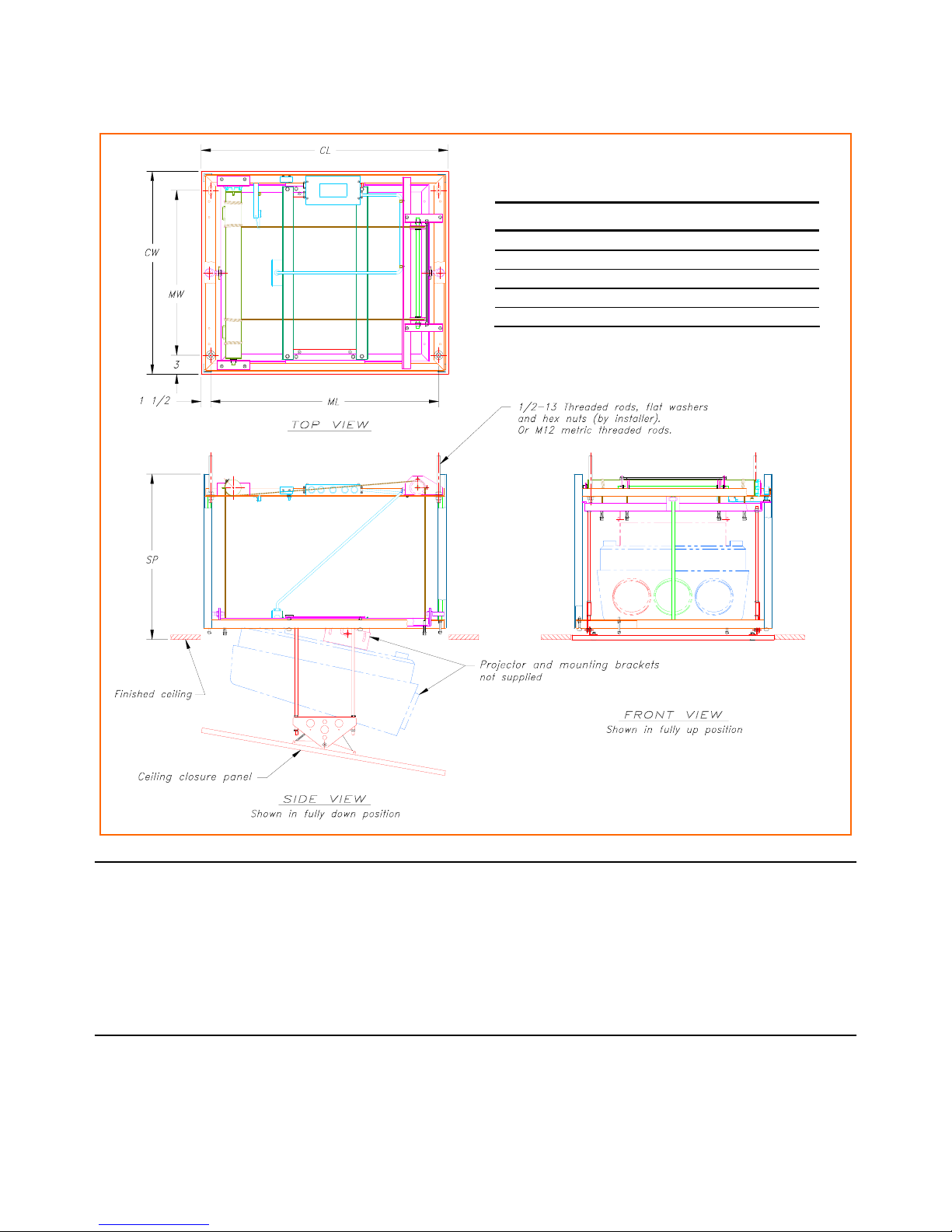

The most common method of installing the VU-PRO projector lift is to suspend it on four, 1/2-

13 threaded rods, from any convenient overhead support. Vertical alignment and leveling is

accomplished by individual adjustment of the threaded rods. Horizontal stability may be

accomplished by guy wires or from contact with the framing around the opening for the projector

lift. The overhead support can often be adapted from the existing building structure, or, if

necessary, constructed specially for this purpose. However constructed, the support must be

capable of sustaining the following loads:

Model VT14X 80 lbs. + Projector Weight

Model VT18X 100 lbs. + Projector Weight

Model VT22X 120 lbs. + Projector Weight

It is important to remember that this will be a continuous dead weight for the life of the

installation. The solidness, or rigidity, of the support structure needs to be sufficient to support

this load without a slow movement, or relaxation, over time.

Following are the primary steps involved in the planning and completion of a standard

installation.

MECHANICAL INSTALLATION

A - DETERMINE PROJECTOR LOCATION

1. Location of the ceiling opening. How critical this location has to be will depend on the

projector being used.

Projectors equipped with a zoom lens can focus the intended image size through a range

of distances of several feet variation. For this reason the exact distance, projector to

screen surface, need only be held within the particular focus range specified by the

projector manufacturer for the intended screen size.

For projectors with a fixed focal length lens, the exact distance, projector lens to screen

surface, becomes much more critical. The projector will have a fairly short range of fine

focus adjustment, and the final installation must end up with the projector located within

this range. It is important to know what this range is, so that you will have a feel for how

critical the projector location actually is.

Focus distance, or throw distance, is usually specified by the manufacturer as the

horizontal distance, face of the projector lens to the face of the screen. Sometimes it is

expressed as the downward angled, straight-line distance, from the center of the lens to

the center of the projected image. Since these two measures are different, it is important

to know which you are working with, before laying out the job.