8

Wurth assures the owner of his equipment, identied by the date

of issue of the purchase invoice, a warranty of two (2) years, as

follows:

1. The warranty period begins on the date of the commercial

invoice.

2. Within the warranty period, the hand labor and the components

replaced by manufacturing defect will be provided for free as

long as duly proved by Wurth.

3. Third-party manufacturing equipment that makes up the

Wurth equipment (such as motors, electrical equipment, belts

etc.) are subject to the terms and conditions of warranty of their

respective manufacturers.

4. In case of exchange for the warranty, please return the

defective part for the manufacturer urgently.

5. Costs and risks of transport will be by the machine owner.

6. Equipment installation expenses and workplace adaptations

are due to the machine owner.

7. When you notice any defect or malfunction when receiving

the equipment, get in touch immediately with the manufacturer

or resale. Do not turn it on.

8. Not included in this warranty technical visits aimed at cleaning

or adjustments caused by wear, resulting from normal use of

the equipment.

9. The warranty does not cover problems caused by mistreatment,

carelessness, misuse or inappropriate use of the functions

designed for this equipment in this manual, as well as poorly

executed operations by untrained operators to operate it.

10. Wurth is not responsible for lost productivity, direct

or indirect damages caused to the owner of the equipment or

to third parties, or any other expense, including lost prots.

11. Even under warranty, you may lose its validity as follows:

WARRANTY TERMS

a) Application of non-original

components;

b) Alteration of its original features;

c) Lack of proper maintenance;

d) Improper use of the equipment;

e) Change in equipment or electronic

connections;

f) Damage caused by

mechanical shock or exposure to

unsuitable conditions (humidity, salt

spray, corrosive agents, etc.);

g) Damage caused by bad

weather (oods, ooding, lightning,

power outages etc.).

• Do not use other tools than recommended.

• Do not apply lubricant to the tools during use.

• Do not operate without all parts of the machine properly

assembled.

• Do not put your hands with in 10cm (4in) from the manual

cutter.

• Do not reach into closed/hidden parts of the machine unless it

is turned o and unplugged.

• Do not use lubricants or cleaners (particularly sprays and

aerosols) in the vicinity of the plastic guard. The polycarbonate

material used in the guard is sensitive to certain chemicals.

WARNING: Some dust created by the act of sanding, cutting,

grinding, drilling and other construction-related activities

contains chemicals that can cause cancer, birth defects or other

reproductive harm. Some examples of these products are: Lead-

based paint; crystal silica bricks, concrete and other masonry

products; and arsenic and chromium from chemically

treated wood.

CAUTION: Do not connect the unit to the power outlet until all

instructions have been read and understood. Always tighten the

adjustment tabs before using the machine. Think: “I can prevent

accidents”.

Do not operate the machine unless the guards are in their proper

places. Always use protective goggles.

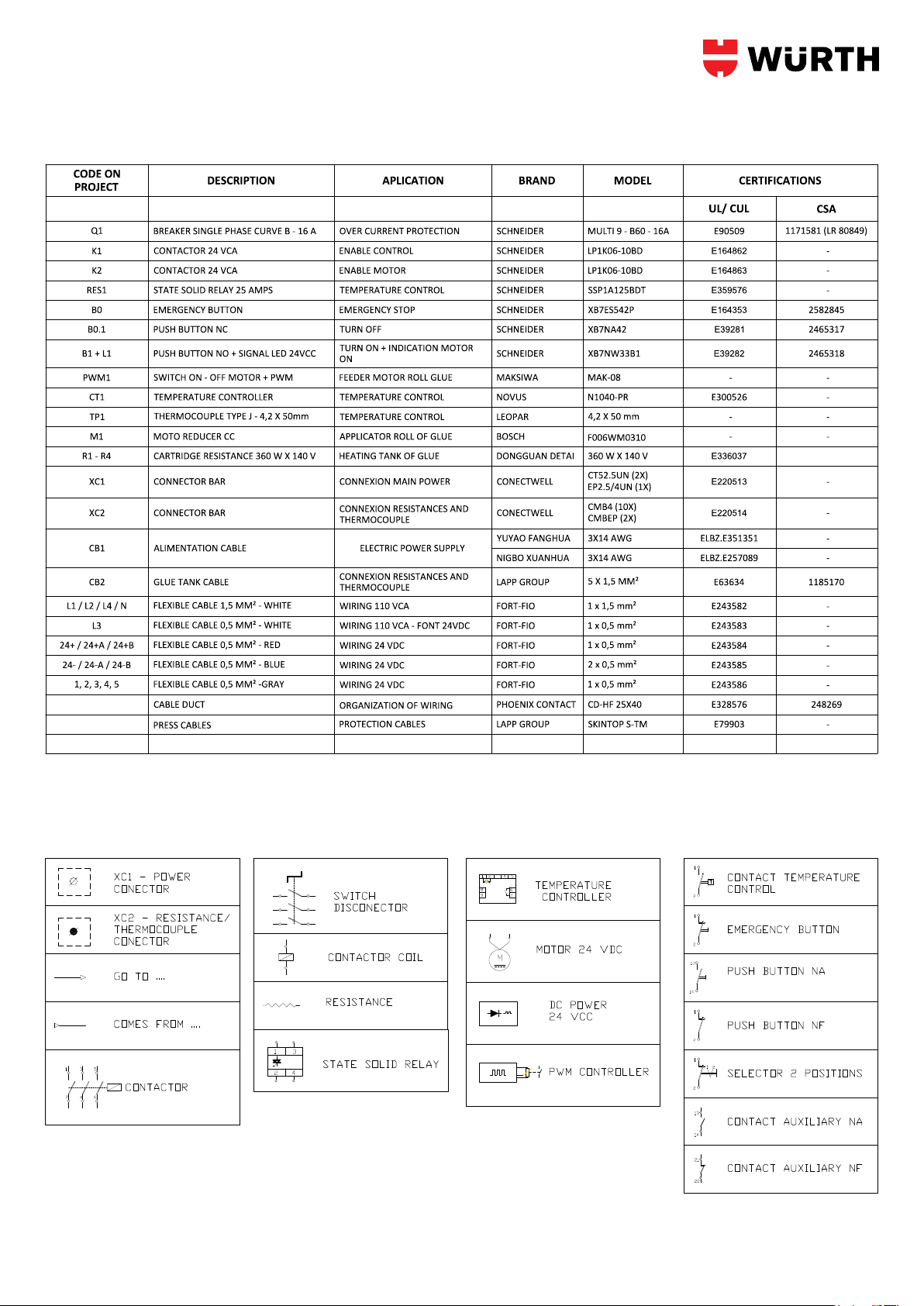

Electrical connection

The W-CBC.EC edge bander has engine 1-phase 110V. To avoid

burning risk, check the voltage of your outlet before starting the

machine. If necessary, make the change to your power source

with the help of a qualied professional.

Ensure that your power supply is in accordance with that

designated on the board. A 10% decrease in voltage or more

will cause loss of power and overheating. All machines are

tested at the factory. If this machine does not turn on, check the

electricity supply.

Check the compatibility of your outlet and plug in the machine.

Do not do patches and adaptations.

To avoid electrical shock and damage to the equipment always

ground the machine.

Familiarization

Place the machine on a smooth, at surface. Check the pictures

and watch the descriptions in this manual to familiarize yourself

with all parts and locations.

For any further assistance, contact us at: +1 (844) 319-6594