WAGNER AquaCoat 5010 GA 5000EAW User manual

Other WAGNER Paint Sprayer manuals

WAGNER

WAGNER Paint Crew User manual

WAGNER

WAGNER ProSpray 27 User manual

WAGNER

WAGNER P20 0552488 User manual

WAGNER

WAGNER W200 User manual

WAGNER

WAGNER Basic 8000 Operational manual

WAGNER

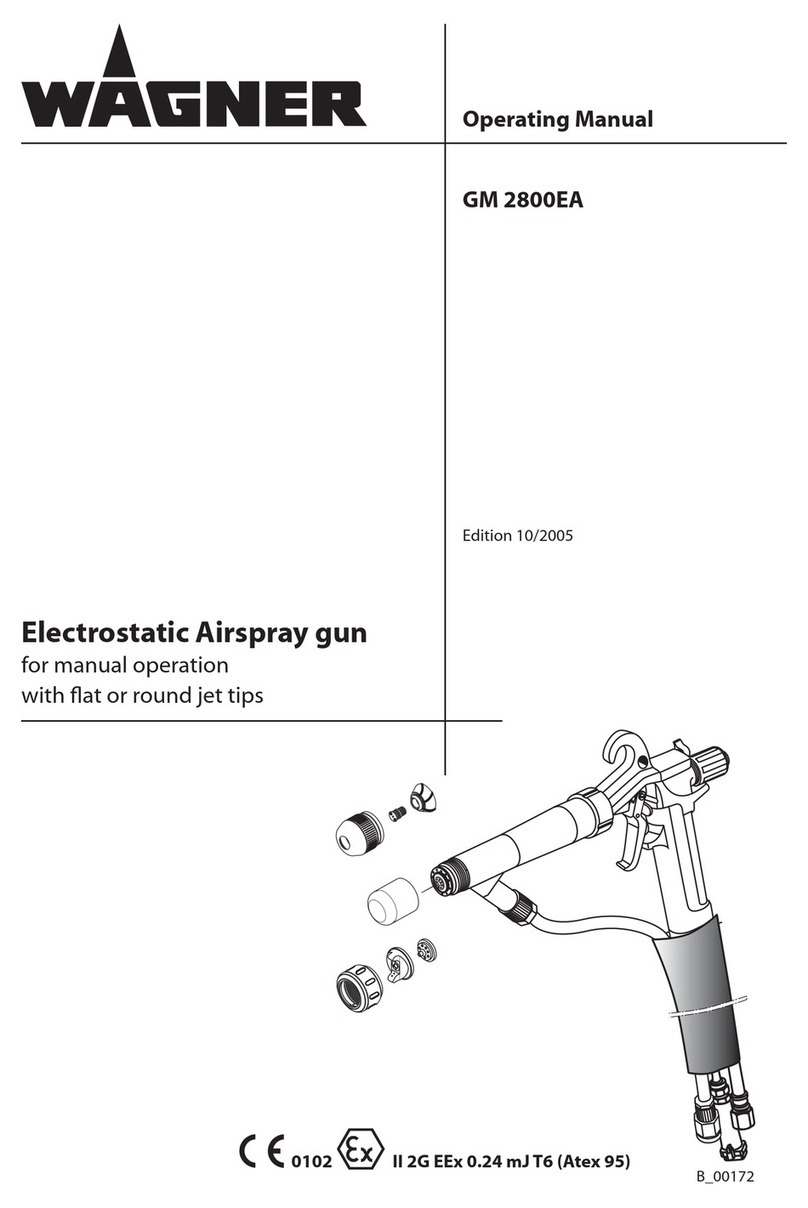

WAGNER GM 2800EA User manual

WAGNER

WAGNER CONTROL PRO 250 M User manual

WAGNER

WAGNER Super Finish 23 PLUS User manual

WAGNER

WAGNER PC 15 User manual

WAGNER

WAGNER WallPerfect W665 User manual

WAGNER

WAGNER FinishControl 5000 User manual

WAGNER

WAGNER F230 User manual

WAGNER

WAGNER ProjectPro 213 Extra User manual

WAGNER

WAGNER AquaCoat AirCoat GM 5000EACW User manual

WAGNER

WAGNER FC3500 User manual

WAGNER

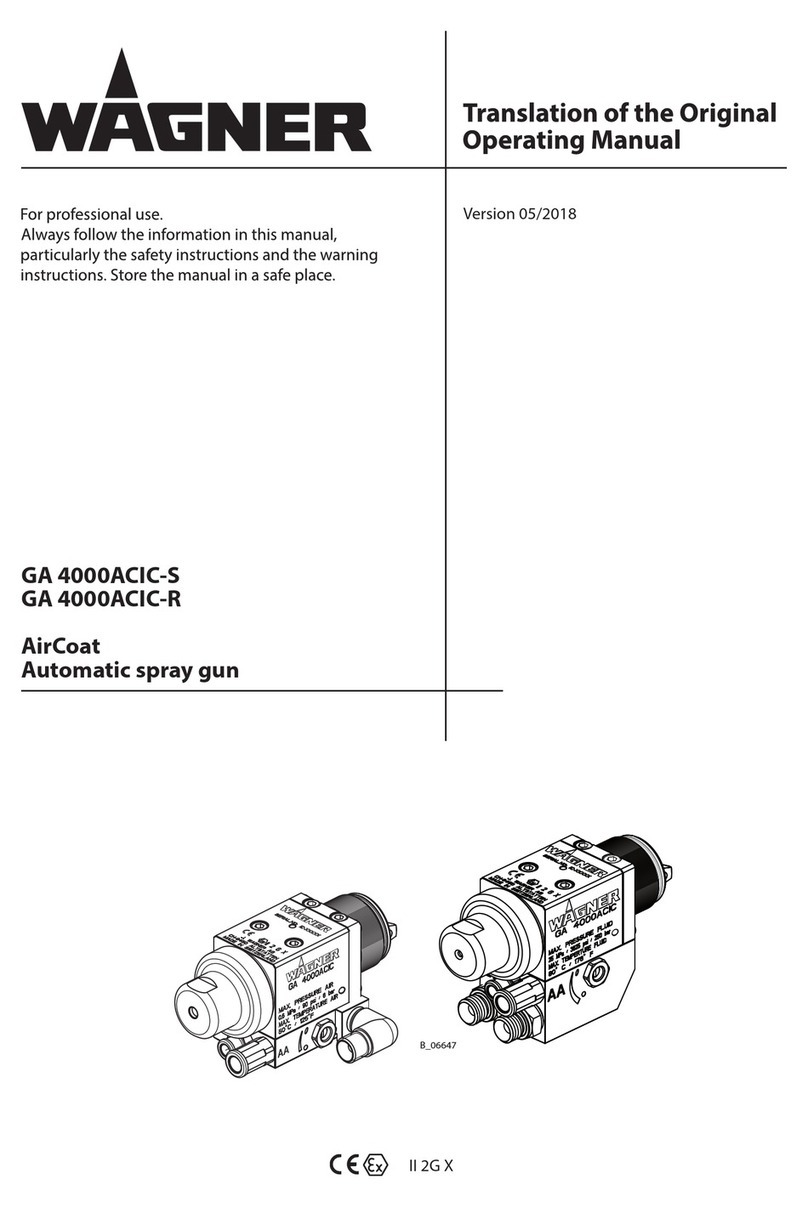

WAGNER GA 4000ACIC-S Operational manual

WAGNER

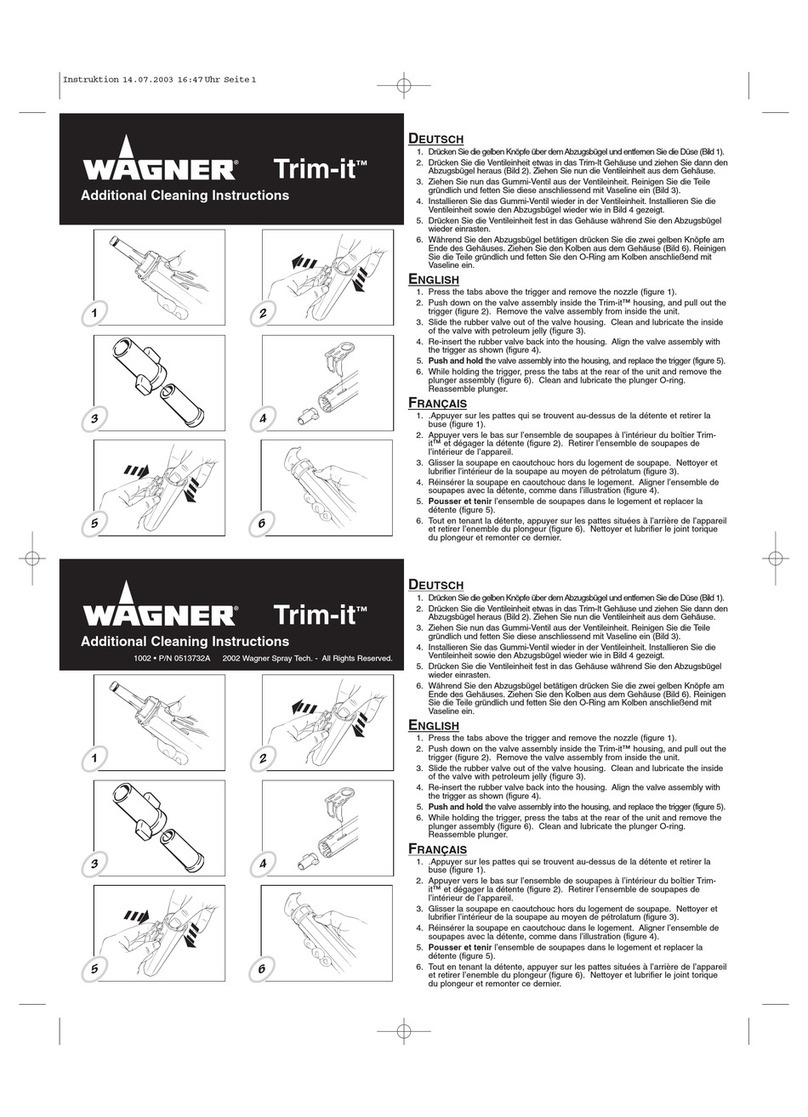

WAGNER TRIM-IT User manual

WAGNER

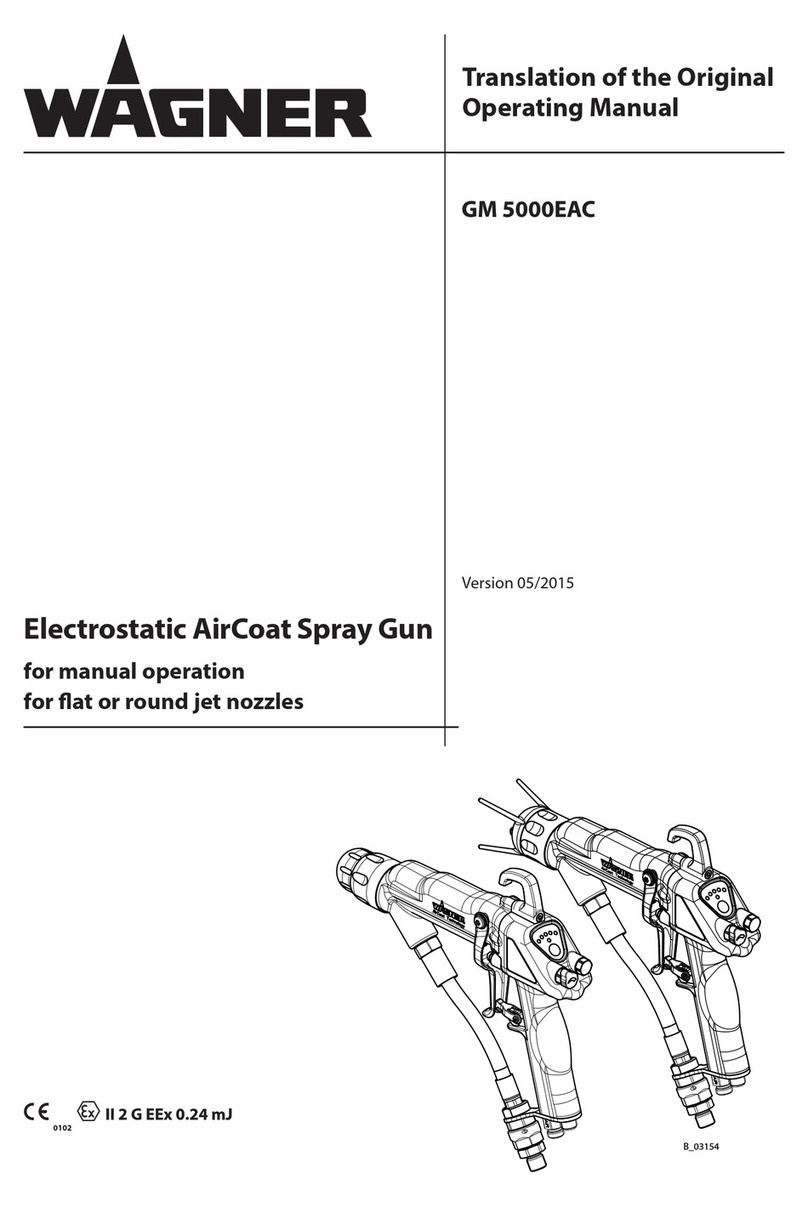

WAGNER GM 50000EAC Operational manual

WAGNER

WAGNER WallPerfect W 985 E User manual

WAGNER

WAGNER ProSpray 3.25 User manual

Popular Paint Sprayer manuals by other brands

zogics

zogics Z-DAS instruction manual

KISANKRAFT

KISANKRAFT KK-KBS-165 Operation manual

Matrix

Matrix SG 650 Translation of the original instructions

Anest Iwata

Anest Iwata SGA-3 Installation, use & maintenance instruction manual

paasche

paasche VV Instructions and parts list

Carlisle

Carlisle DeVilbiss JGA-510 Service manual