6 • Important Notes

Safety Information

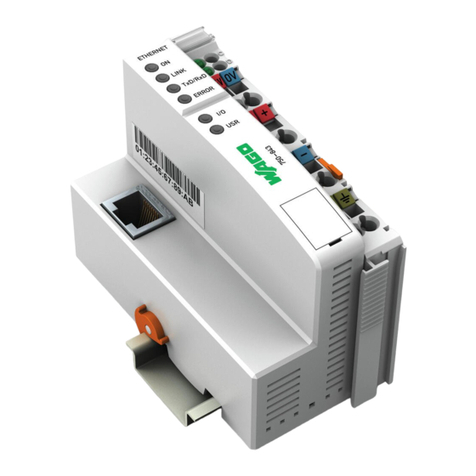

WAGO-I/O-SYSTEM 750

Telecontrol Quick-Start Manual

1.4 Safety Information

NOTICE

Switch off the power before replacing any components!

In the event of deformed contacts, the module in question is to be replaced, as

its functionality can no longer be ensured on a long-term basis.

The components are not resistant against materials having seeping and

insulating properties. Belonging to this group of materials are: e.g., aerosols,

silicones, triglycerides (found in some hand creams).

If it cannot be ruled out that these materials appear in the component

environment, then additional measures are to be taken:

- Installation of the components in an appropriate enclosure.

- Handling of the components only with clean tools and materials.

NOTE

Soiled contacts may only be cleaned with ethyl alcohol and a leather cloth. In

doing so, attention must be paid to the ESD information.

Do not use contact sprays, which in extreme cases could impair the operation

of the contact.

The WAGO-I/O-SYSTEM 750 and its components are an open system. It

must only be assembled in housings, cabinets or in electrical operation

rooms. Access must only be given via a key or tool to authorized, qualified

personnel.

The relevant valid and applicable standards and guidelines regarding the

installation of switch cabinets must be observed.

ESD (Electrostatic Discharge)

The modules are equipped with electronic components that may be destroyed

by electrostatic discharge. When handling the modules, ensure that the items

in the environment (personnel, workplace and packaging) are well grounded.

Do not touch conducting parts; e.g., gold data contacts.

1.5 Scope of Validity

This quick-start manual describes the programming of the 750-872 controller

as the master of an outstation as defined by IEC 60870-5-101 and -104 with

some basic modules from the WAGO-I/O-SYSTEM for telecontrol.

Detailed information relating to handling, assembly and start-up is described

in the "Ethernet TCP/IP 750-872" and "WAGO-I/O-PRO CAA" manuals. This

documentation is therefore only valid in conjunction with the appropriate

manuals.