DHS40 Series High Performance Hand-Held Infrared Sensors User Manual

2

Contents

Heat Spy Warranty ..................................................................................................................................................... 4

Safety Instructions.................................................................................................................................................. 4

Acceptable Operation ........................................................................................................................................ 4

Unacceptable Operation .................................................................................................................................... 4

Instrument Disposal ........................................................................................................................................... 4

Laser Warning..................................................................................................................................................... 4

Includes .............................................................................................................................................................. 5

DHS40 Specifications.............................................................................................................................................. 5

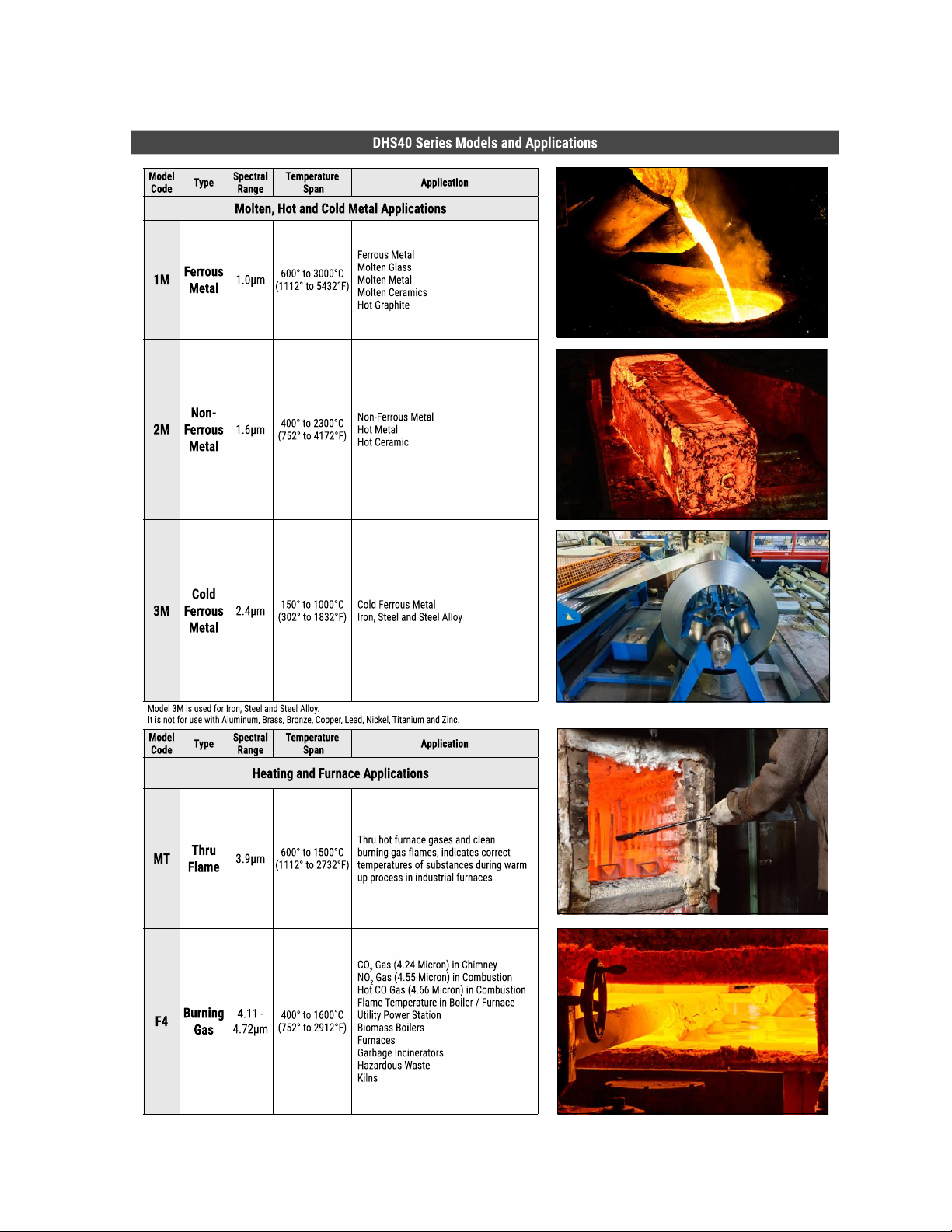

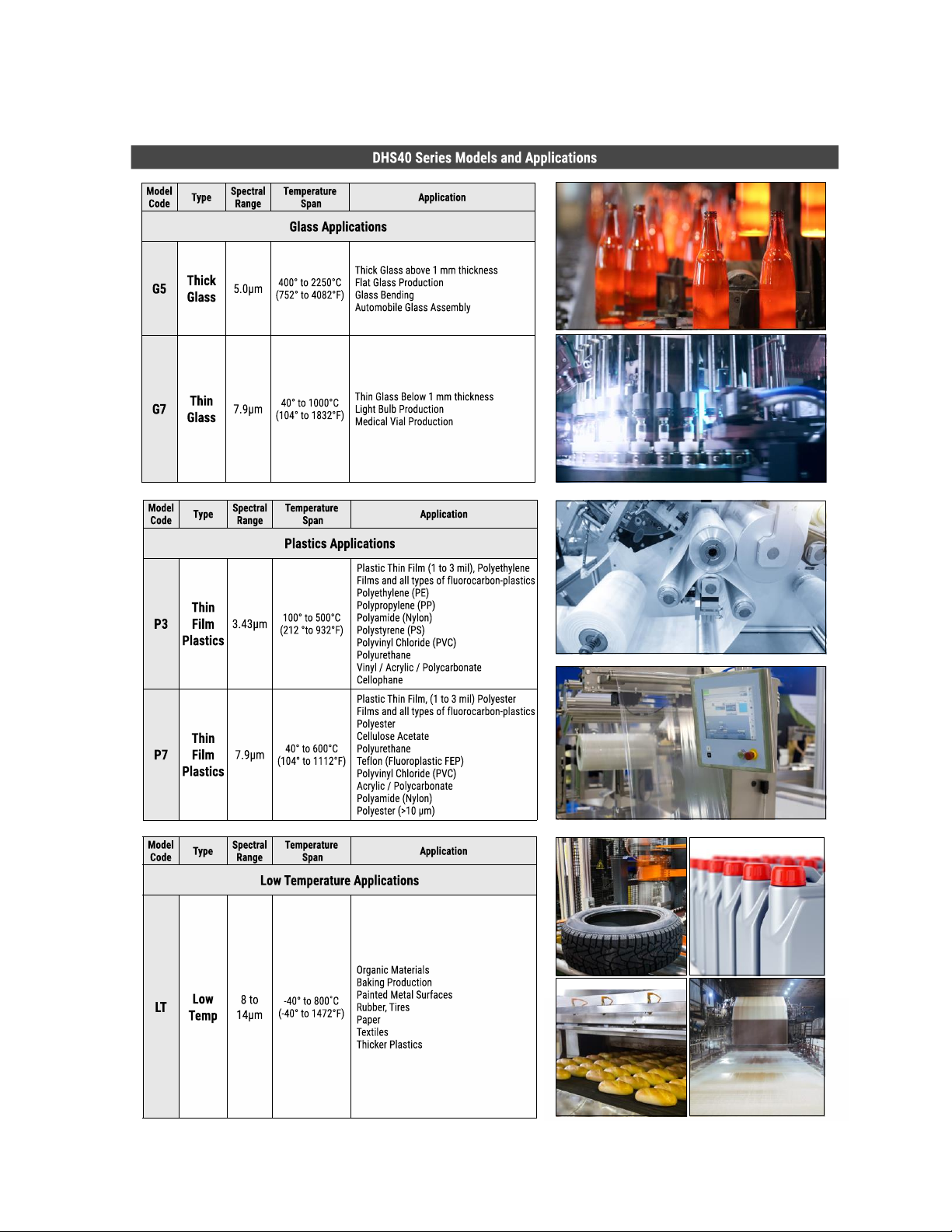

DHS40 Product Line................................................................................................................................................ 6

Principle of Operation ................................................................................................................................................ 8

Basics of Infrared Thermometry ............................................................................................................................ 8

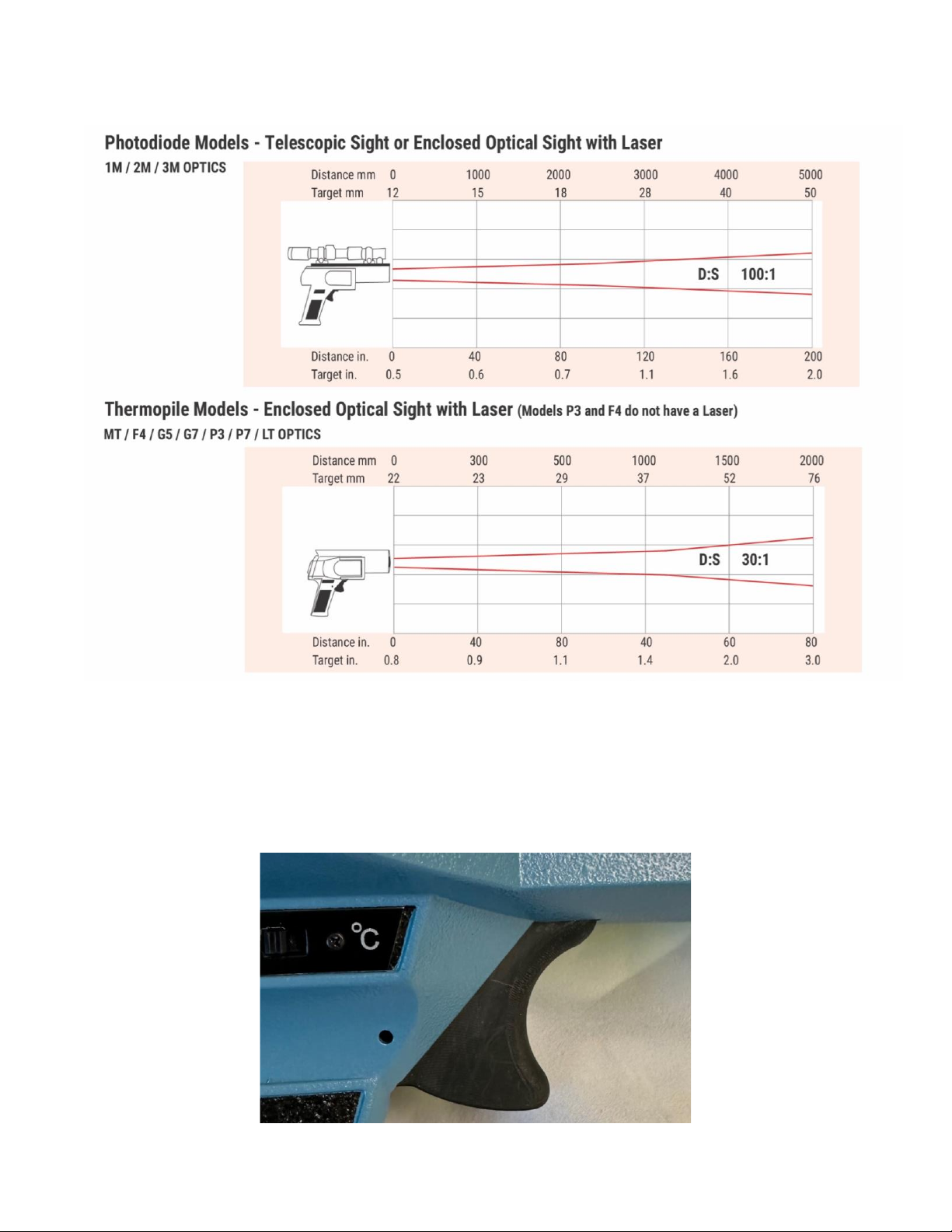

Target Ratio............................................................................................................................................................ 9

DHS40 Optics Diagrams........................................................................................................................................ 10

DHS40 Features.................................................................................................................................................... 10

Trigger .............................................................................................................................................................. 10

LCD Display ICONS............................................................................................................................................ 11

Control Panel.................................................................................................................................................... 13

°F / °C Switch .................................................................................................................................................... 14

Laser Switch...................................................................................................................................................... 14

Laser ................................................................................................................................................................. 15

Laser Specifications .......................................................................................................................................... 15

Caution .................................................................................................................................................. 15

Optical Sight ..................................................................................................................................................... 15

Telescopic Sight................................................................................................................................................ 16

Tri-Pod Connection........................................................................................................................................... 16

Trigger Lock ...................................................................................................................................................... 16

Power Source ................................................................................................................................................... 17

Emissivity.............................................................................................................................................................. 17

Typical Emissivity Values.................................................................................................................................. 18

Maintenance and Troubleshooting...................................................................................................................... 19

Return for Calibration Service.............................................................................................................................. 19

Appendix I: Emissivity of Common Materials .......................................................................................................... 20