General Applicable Safety Precautions

All applicable accident prevention rules and regulations as well as other

recognized industrial safety and health rules and regulations must be observed

at all times

Use the spray gun only in well-ventilated rooms. Fires, naked light and smoking are

strictly prohibited in the working area. WARNING - during the spraying of flammable

materials (e.g. lacquers, adhesives, cleaning agents, etc), there is an increased risk to

health as well as an increased risk of explosion and fire.

An adequate grounding of the extrusion gun is to ensure, for example, through the

fluid hose (maximum resistance 106Ω).

Before carrying out any maintenence or service work, always ensure that the air and

material feed to the spray gun have been de-pressurized. The extremely high pressure

at the gun or pump outlet can cause serious injury.Risk of injury!

When spraying make sure your hands and other body parts are clear from the

pressurized nozzle of the extrusion gun - the extremely high injection pressure can

cause serious injury.

Use diaphragm or piston pumps only in the context of a fluid regulator to prevent the

maximum allowable operating pressure of 350 bar can not be exceeded.

Do not point the extrusion gun towards people or animals - risk of injury.

Always observe the spraying and safety instructions given by the manufacturers of

the spraying material and the cleaning agent. Aggressive and corrosive materials in

particular can be harmful to health.

Exhaust air containing particles (overspray) must be kept away from the working

area and presonnel. In spite of these measures, always wear the regulation

breathing masks and protective overalls when using the gun. Airborne particles

represent a serious health hazard!

After carrying out assembly or maintenance work, always ensure that all nuts, bolts

and screw connections have been fully tightened before the gun is used.

Use only original replacement parts, since WALTHER canonly guarantee safe and

fault-free operation for original parts.

For further information on the safe use of the spray gun and the spraying

materials, please contact WALTHER Spritz- und Lackiersysteme GmbH, D-42327

Wuppertal.

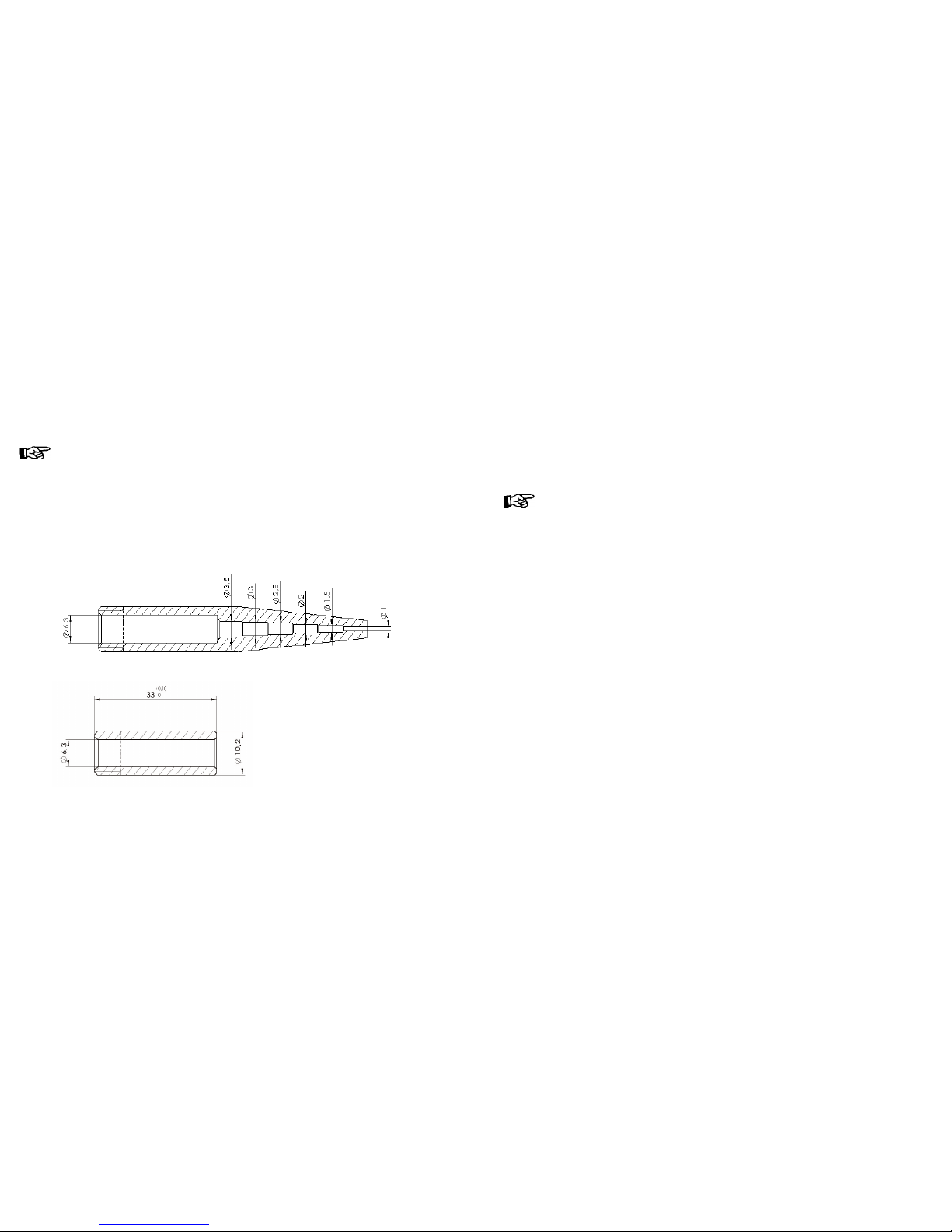

Supply Line Connection

Warning

Use the pump only in the context of a fluid regulator to prevent the maximum

allowable operating pressure of 350 bar can not be exceeded.

Material connection:

Attach the supply line at the connection item 20 of the extrusion gun. Maintain a

tight screw.

Notice

Use only grounded fluid hoses with a maximum total length of 150 m in order to

ensure a continuous ground and they must be resilient enough for an operating

pressure of 350 bar. Check the electrical resistance of the fluid hoses at least once

a week. If the hose does not have a label, on which the maximum electrical

resistance is specified, the maximum resistance values can be obtained from the

manufacturer. If the resistance exceeds the recommended limits, replace the hose

immediately concerned.

The gun is now ready for operation.