3

Quick Install Guide........................................................................... 4

Components Available for Installation ........................................ 6

Do’s & Don’ts...................................................................................... 7

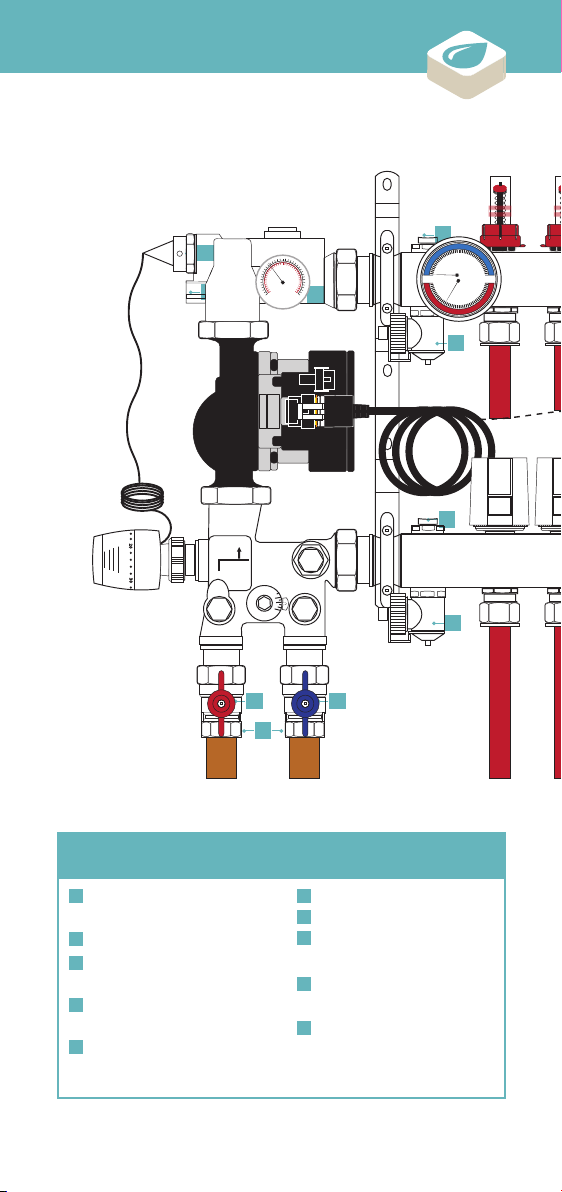

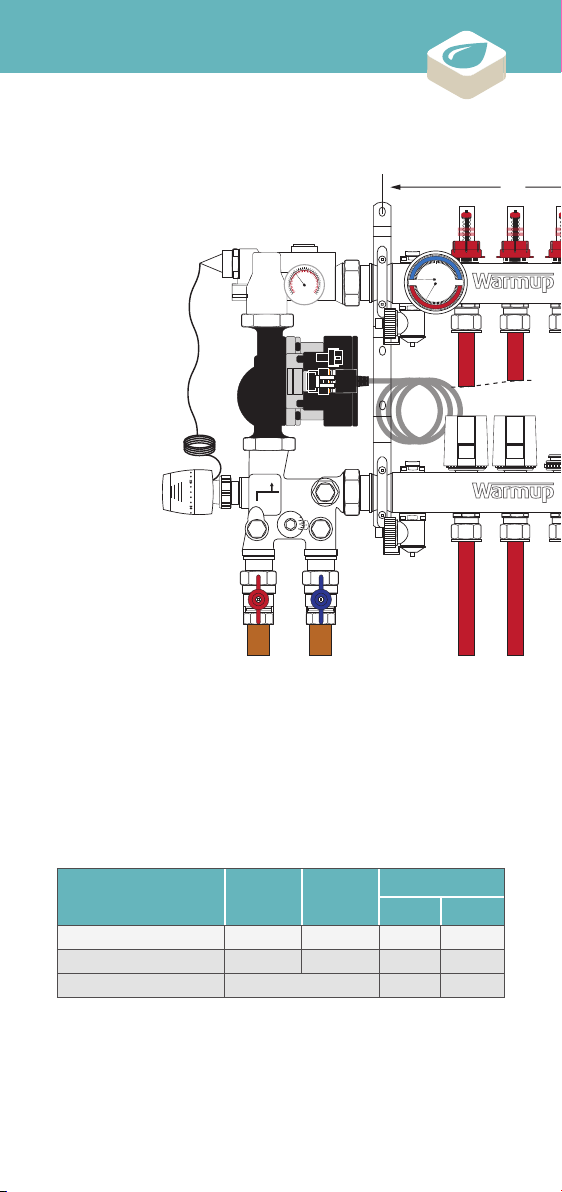

Overview ............................................................................................ 8

Dimensions...................................................................................... 10

Step 1 - Location Considerations .............................................. 12

Step 2 - Assembly.......................................................................... 13

Step 3 - Circuit Purging & Filling................................................. 18

Step 4 - Pressure Testing ............................................................ 20

Step 5 - Circuit Balancing............................................................ 22

Step 6 - Actuator Mounting......................................................... 24

Step 7 - Circulator Mode Setting................................................ 25

Step 8 - Capillary Thermostat Mounting.................................. 26

Step 9 - Temperature Settings.................................................... 27

Step 10 - Initial Heating Cycle .................................................... 28

Troubleshooting ............................................................................. 30

Layout Plan...................................................................................... 33

Commissioning Log....................................................................... 34

Warranty........................................................................................... 36

Technical Specifications ............................................................... 38

WARNING

Your Warmup® Underfloor heating system has been designed so that

installation is quick and straight forward, but as with all electrical

systems, certain procedures must be strictly followed. Please

ensure that you have the correct heater(s) for the area you wish

to heat. Warmup plc, the manufacturer of the Warmup® DCM-Pro

System, accepts no liability, expressed or implied, for any loss or

consequential damage suered as a result of installations which in

any way contravene the instructions that follow.

It is important that before, during and aer installation that all

requirements are met and understood. If the instructions are

followed, you should have no problems. If you require help at any

stage, please contact our helpline.

You may also find a copy of this manual, wiring instructions and other

helpful information on our website:

www.warmup.co.uk

Contents