01

06

02

07

03

08

04

09

05

10

Quick Start

1 Power on your SMAN by holding the ON/OFF

button for 1 second.

2 Select desired units (English or Metric) by

pressing the UNITS button (SMAN3) or hold-

ing the ENTER button for 1 second (SMAN2).

3 Calibrate temperature and/or pressure as

needed. See calibration sections for more

details.

4 Connect to the system.

5 Pressthecircularbuttontoselectyourdesired

function.

Certifications

C-Tick (N22675)

CE

RoHS Compliant

Description

Your SMAN is the state-of-the-art portable

digital refrigerant manifold and vacuum gauge

(SMAN3) for A/C and refrigeration service. Your

SMAN combines high pressure manifold gauges,

a superheat/subcooling calculator, micron

gauge for vacuum (SMAN3), and temperature

measurements into one easy-to-use instrument.

Your SMAN calculates and displays target

superheat and actual superheat to ensure

proper charging of a unit. Use your SMAN as a

dual temperature instrument to simultaneously

display two temperatures using any K-type

thermocouple.

Your SMAN is designed to meet the demands

of the HVAC/R technician with a ruggedized

rubber boot for durability, a metal hanger

for easy storage and a high quality nylon

case. A bright blue backlight and very large,

easily viewable display lets you see your

measurements in any work environment. SMAN

has a very intuitive user interface and extremely

long battery life.

Your SMAN comes pre-programmed with the

most accurate P-T charts for the most common

refrigerants in the field so you are always

prepared for any job.

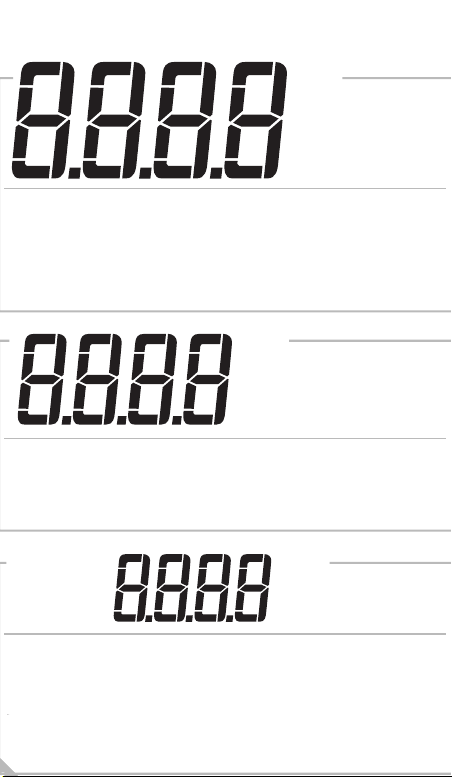

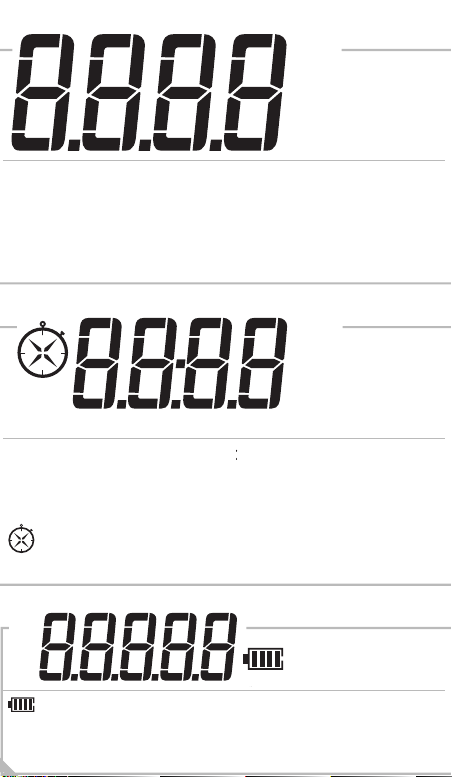

Display

1 Insert K-type thermocouple plugs here.

2 Temperature calibration pots.

3 Press to zero atmospheric pressure.

4 Press tolinear adjust pressurecurve.(See

Advanced Pressure Calibration section.)

5 Press toengage backlight.Holdwhen

powering on to toggle Auto Power O.

6 Press/hold to cycle through refrigerants.

7 Hold 1 second to toggle power on/o.

8 Press up or down arrow to adjust values.

9 Press to confirm selection. For the

SMAN2, hold 1 second to adjust units.

10 Hold to enter alarm setup mode. (SMAN3)

11 Press to toggle through temperature tests.

Hold to auto-toggle.

12 Press to adjust units. (SMAN3)

13 Turn clockwise to close Low side port.

14 Turn clockwise to close High side port.

Functions

Standard Pressure

1 Connect your SMAN to the system using EPA approved 1/4in

refrigerant hoses.

2 Read pressures directly from the upper display.

Superheat and Subcooling

1 Press circular button to cycle through temperature modes until

SH and SC are shown. While the SMAN can show superheat and

subcooling simultaneously, most technicians will only measure

one, depending on the system.

2 Choose the appropriate refrigerant using the REFRIGERANT

button.

3 Connect the K-type thermocouple and EPA approved refrigerant

hoses to your SMAN.

4 Connect your SMAN to the system:

Superheat: Hand tighten low side hose to suction line service

port. Place the thermocouple on the suction line between the

evaporator and compressor, no closer than 6 inches to compressor.

Subcooling: Hand tighten high side hose to liquid line service

port. Place the thermocouple on the liquid line between the

condenser and expansion valve (TXV), as close to the service port

as possible.

5 For reliable readings you must let the system run continuously for

15 minutes to stabilize.

6 Add or remove refrigerant using the low and high side valves as

needed. If adding or removing refrigerant, let the system stabilize

again for 15 minutes before reading the measurement.

T1 T2 Direct

1 Press circular button until T1 andT2 are shown.

2 Plug in any K-type thermocouple into T1 and/or T2.

3 Read the temperature directly from the display.

Saturation

Shows vapor (VSAT) and liquid saturation (LSAT) temperatures,

based on the pressures measured and the refrigerant selected.

Target Superheat

1 Press circular button until Target SH is shown.

2 Plug the ATWB1 Wet bulb K-type thermocouple intoT1 and ATA1

Dry bulb K-type thermocouple into T2.

3 Use the arrow buttons to select which temperature you want to

measure rst. A blinking value means the SMAN is displaying the

real-time temperature.

4 For IDWB, wet the sock of the ATWB1. Clip it to the front of

the evaporator coil or lter. When the wet bulb temperature

reaches its lowest point and stabilizes. ENTER locks the reading.

"OL" will show if reading outside wet bulb charts. Re-take the

measurement.

5 For ODDB, clip the ATA1 thermocouple to the side of the

condenser. Once reading is stable, press ENTER. "OL" will show if

reading outside dry bulb charts. Re-take the measurement. For

best results, keep the ATA1 away from direct sunlight.

6 Once both IDWB and ODDB are set, the Target Superheat will

display in the lower left corner of the display. If the inputted IDWB

and ODDB temperatures indicate theTarget Superheat is negative,

"OL" will display in the lower left corner.

7 To change either IDWB or ODDB, press the UP/DOWN arrow button

until the label (IDWB or ODDB) you wish to change is blinking.

Press ENTER and the value will begin to blink. Re-take the

measurement and press ENTER to lock in the new measurement.

The newly calculated Target Superheat will be displayed in the

lower left corner.

8 To clear both IDWB and ODDB at the same time, press the ENTER

button.This will only work when a Target Superheat or "OL" is

displayed in the lower left corner.

Pulling a Vacuum (model SMAN3)

Follow all manufacturers’ evacuation

procedures over those in this manual.

Note: larger systems may take much longer to

reach a deep vacuum and a dierent evacuation

method or equipment might be preferred.

1 Connect your SMAN3 inline between your vacuum pump and the

system, then power on your SMAN3.

2 Draw a vacuum on the system. The SMAN will automatically

sense the negative pressure and display the vacuum in microns of

mercury. Indicators for increasing or decreasing pressure will be

shown.

3 Press Alarm button to toggle between the High (Hi) alarm, the

Low (Lo) alarm and no alarm. (No display for no alarm.)

(Note: The stopwatch will start when an alarm is selected.

Pressing Alarm will reset the stopwatch.)

4 When the rate of change in pressure is zero or near zero, Stable

will appear in the lower left corner of the display.

Additional Tips:

In order to achieve a deep vacuum as quickly as possible the

following practices are suggested.

1 Use the shortest hoses with the largest diameter available.

2 Remove Schrader cores and core depressors. Core removal tools

like the "MegaFlow Valve Core RemovalTool" can be purchased to

help with this process.

3 Inspect the rubber seals at both ends of your hoses for damage

that may result in leakage.

4 Do not use hoses with low loss ttings when evacuating or

pulling a vacuum on a system.

Set Vacuum Alarms (SMAN3)

1 Hold the Alarm button for one second to enter Alarm Set mode.

2 Press the Alarm button to toggle between Alarm Hi and Lo.

3 Use arrow buttons to adjust each alarm value.

4 Press ENTER to lock both alarms in.

T1 T2

Atmospheric

Pressure

Superheat

Subcooling

T1 T2 Direct Saturation

Target

Superheat

CAL CAL

CAL CAL

Tes t

Pressure

AUTO

OFF

Refrigerant ON/OFF

Enter

Units

Alarm

Digital Manifold + Vacuum Gauge

SMAN3

ODDB

HH:MM:SS

Psig

Kpa

inHg

cmHg

Psig

Kpa

inHg

cmHg

SHT1

VSAT

APO

Microns

HiLo

SetStable

Alarm

IDWB

Target SH

R-

°F°C

SCT2

LSAT

°F°C

°F°C

11

22

3

14

4

5

89

1110 12

67

13