4Warner Electric • 800-825-9050 P-8854-WE • 819-0556

Installation

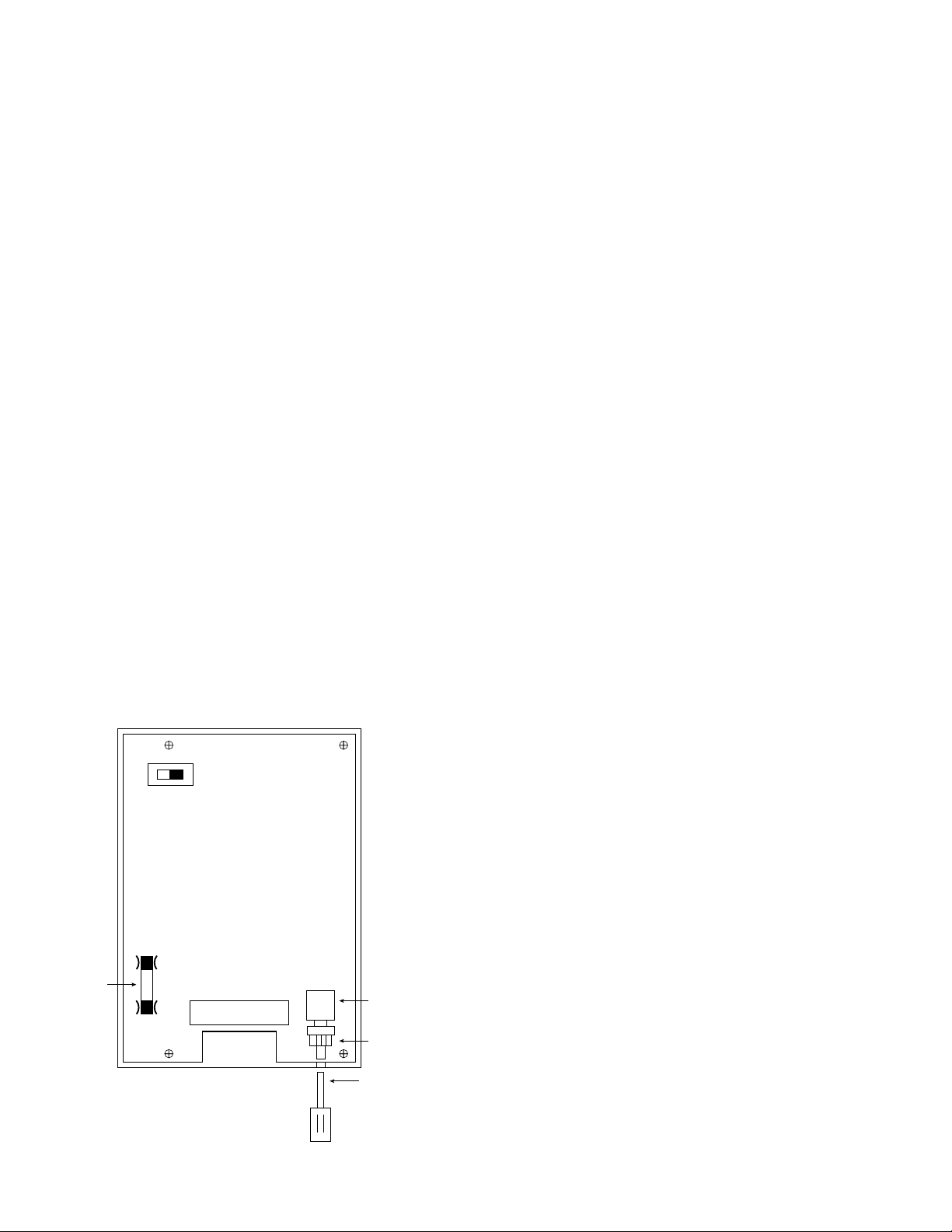

A. For 115VAC: Connect power supply to

terminals 1 and 2. Insure AC input switch is in

the 115 position. For 230VAC: Connect power

supply to terminals 1 and 2. Insure AC input

switch is in 230 position.

B. A chassis ground should be provided as a non-

current conducting ground wire (color coded

green). Connect this ground to the PC board

screw labeled “Chassis GND.”

C. Switching.

• For switching DC side: switch must be

connected to terminals 3 and 4. Switch

open will allow brake to be engaged. Switch

closed will release the brake. For MCS-

805-2 Only: Switch open will allow brake to

be partially engaged and AC power off will

allow brake to be fully engaged.

• For switching AC side: Line power off will

allow brake to be engaged. Line power on

will release brake. Install a jumper between

terminals 3 and 4.

D. Connect the positive terminal of the brake

to terminal 6 on the control and the negative

terminal of the brake to the terminal 5 on the

control.

Brake Release Adjustment

When setting the MCS-805 control, the objective

is to achieve armature release by adjusting the coil

voltage so it counteracts the permanent magnet to

the maximum extent possible. Proceed as follows:

A. Remove the 3/8” hole plug from the housing

for the release adjust potentiometer. While

holding the potentiometer locking mechanism

with 1/2” wrench, loosen the 7/16” locking

nut on the adjustment potentiometer. Ensure

user connected switch S1 is closed (see

Connections on page 5). Turn on AC power.

Turn the potentiometer adjusting screw (through

access hole in enclosure) to the maximum

counterclockwise position. Slowly turn the

adjustment screw clockwise until the brake

armature disengages from the magnet. If the

usual autogap spring is used, this will normally

cause the armature to separate approximately

1/32” from the magnet. If the autogap is not

used, an external release force of approximately

5-10 pounds should be applied by hand, to

detect the point of armature release. Using a

voltmeter, note and record the voltage at this

point.

B. Turn the adjusting screw to the maximum

clockwise position that will normally cause

the armature to be reengaged. If the armature

does not make contact, it should be physically

moved into contact, with caution exercised to

prevent fingers from being injured.

C. Turn the adjusting screw slowly counterclock-

wise until the armature releases through the

same technique as used under (A). Note and re-

cord the voltage, which will be somewhat higher

than the value noted under (A). Adjust the final

voltage setting to the mid-point between the

two readings.

D. While holding the potentiometer locking

mechanism with 1/2” wrench, tighten the

locking nut with 7/16” wrench. Plug access hole

with 3/8” hole plug previously removed. The

brake is then ready for normal operation.

For MCS-805-2 Only: Set partial engagement

torque using the external potentiometer. Switch

connected to terminals 3 and 4 must be open

to make this adjustment. A setting of 10 gives

maximum torque.

115 230

1 2 3 4 5 6

Release

Adjust

Potentiometer

Locking Nut

Screwdriver

Adjust

Chassis

GND

Fuse:

500 ma

FA