Contents

1 Features............................................................................................................................4

2 Safety Symbols used in this Manual.................................................................................4

3 Safety Guidelines..............................................................................................................5

4 Responsibility for Operation or Dama e...........................................................................6

5 Application.........................................................................................................................6

6 Before Startin ..................................................................................................................7

6.1 Transport....................................................................................................................7

6.2 Installation..................................................................................................................7

6.3 Stora e.......................................................................................................................7

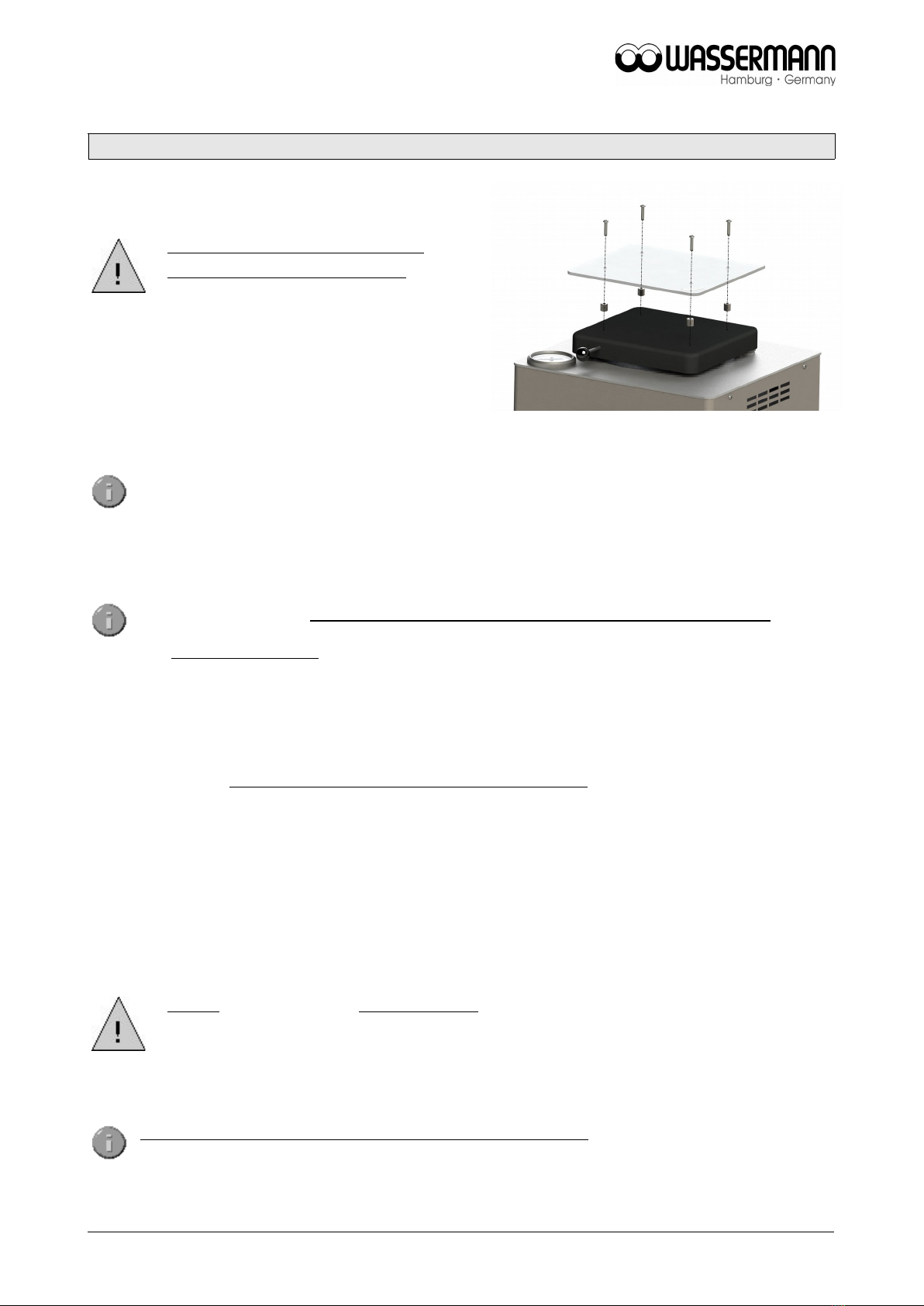

7 Installation/ Start-up..........................................................................................................8

7.1 Settin the correct Pressure.......................................................................................9

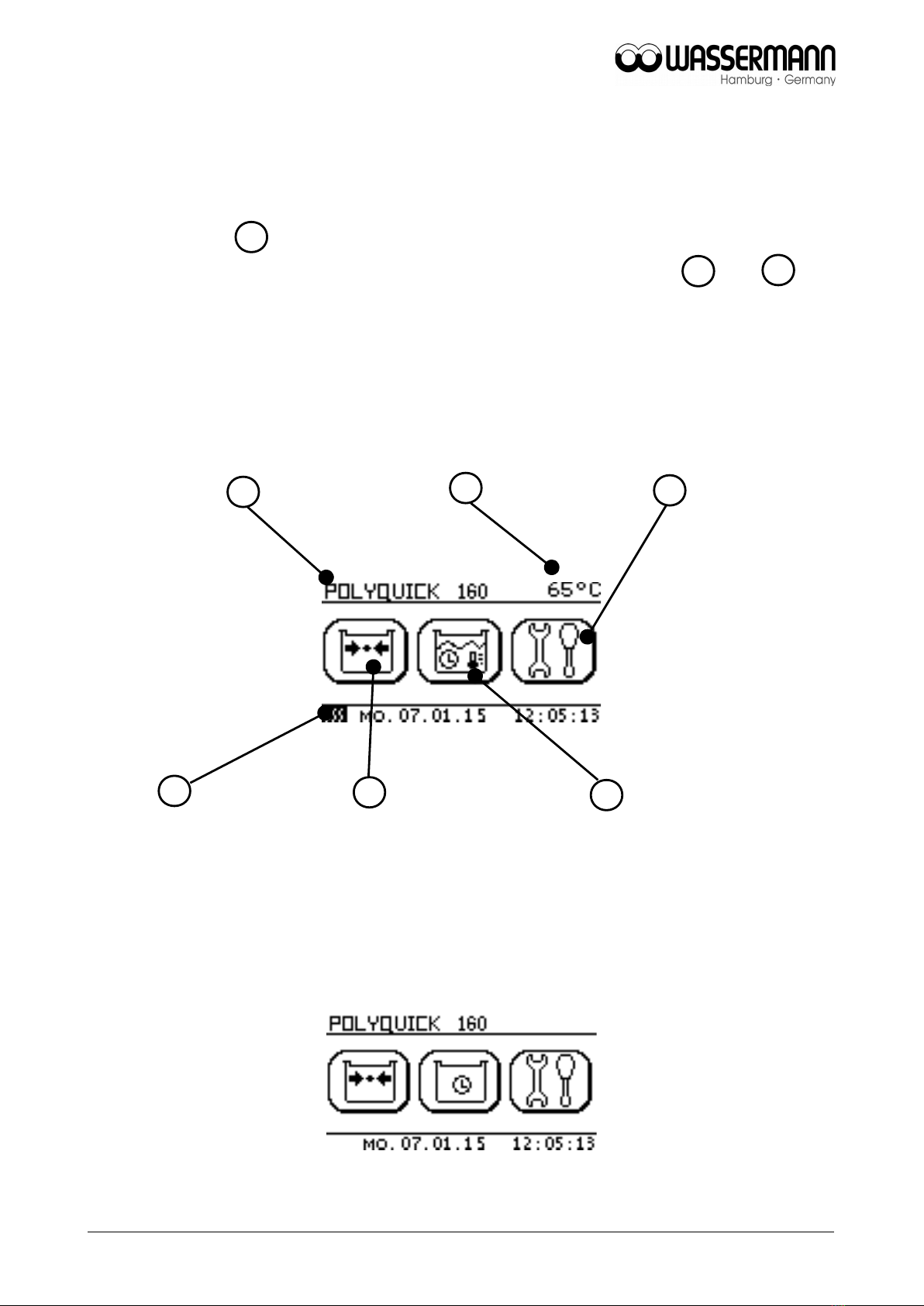

7.2 Start-up.....................................................................................................................10

8 Operation........................................................................................................................17

8.1 General Operatin Instructions................................................................................17

8.2 Operation..................................................................................................................18

9 Troubleshootin ..............................................................................................................19

10 Care and Maintenance..................................................................................................21

10.1 Cleanin .................................................................................................................21

10.2 Maintenance...........................................................................................................21

10.3 Repairs...................................................................................................................21

10.4 Spare Parts.............................................................................................................22

10.5 Service Hotline 0049 (0)40 / 730 926 -20/ -24.......................................................22

10.6 Scope of Delivery/ Accessories..............................................................................22

10.7 Warranty.................................................................................................................23

11 Technical Data..............................................................................................................23

12 Disposin of the Unit.....................................................................................................24

12.1 Information on Disposal for Countries within the EU.............................................24

13 EU Declaration of Conformity.......................................................................................25