Con en s

1 Features..........................................................................................................................3

2 For your safety................................................................................................................3

2.1 Your service manual....................................................................................................3

2.2 Safety guidelines.........................................................................................................4

2.3 Responsibility for operation and damage....................................................................4

3 Applications.....................................................................................................................5

4 Before you start..............................................................................................................5

4.1 Unpacking / Transport.................................................................................................5

4.2 Set-up and storage......................................................................................................5

5 Start-up...........................................................................................................................6

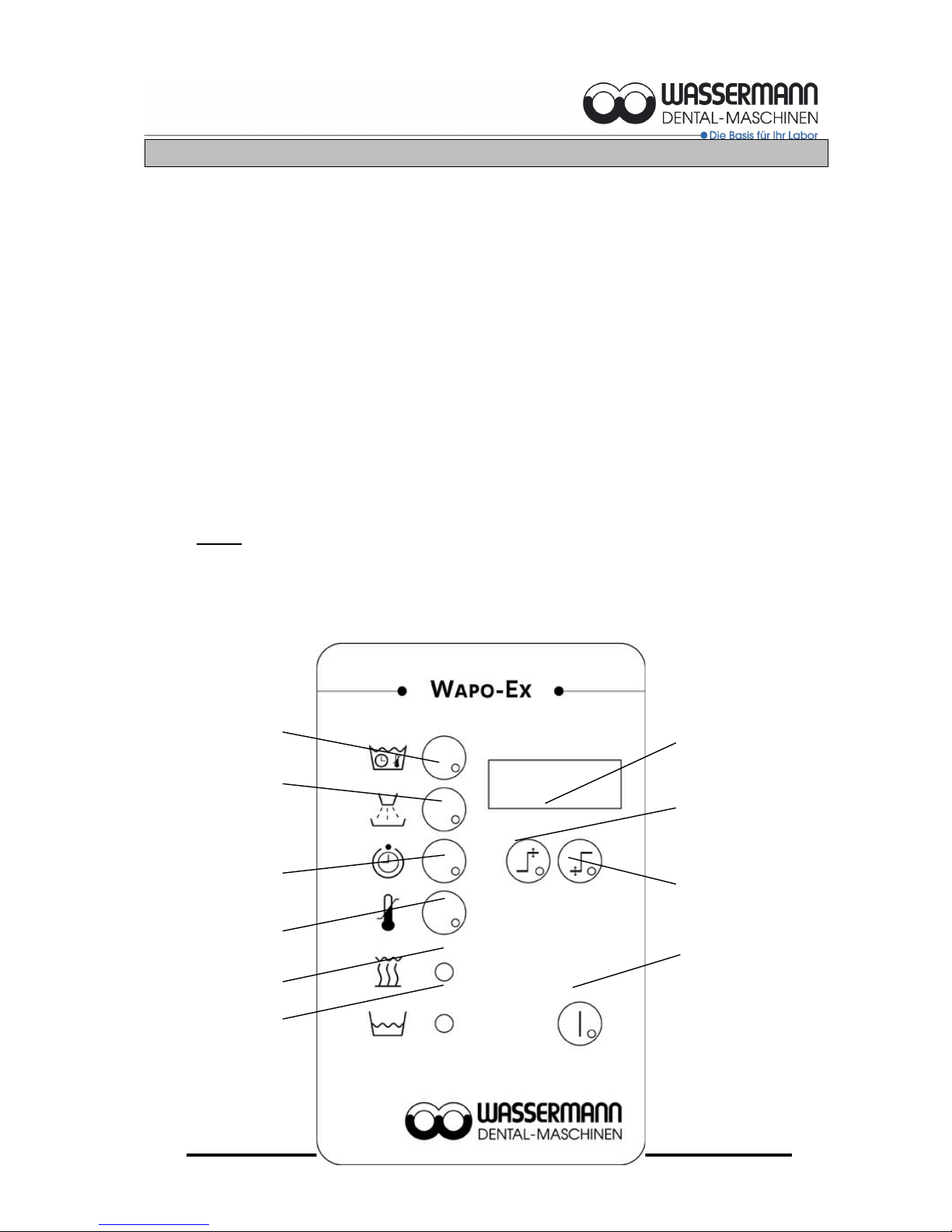

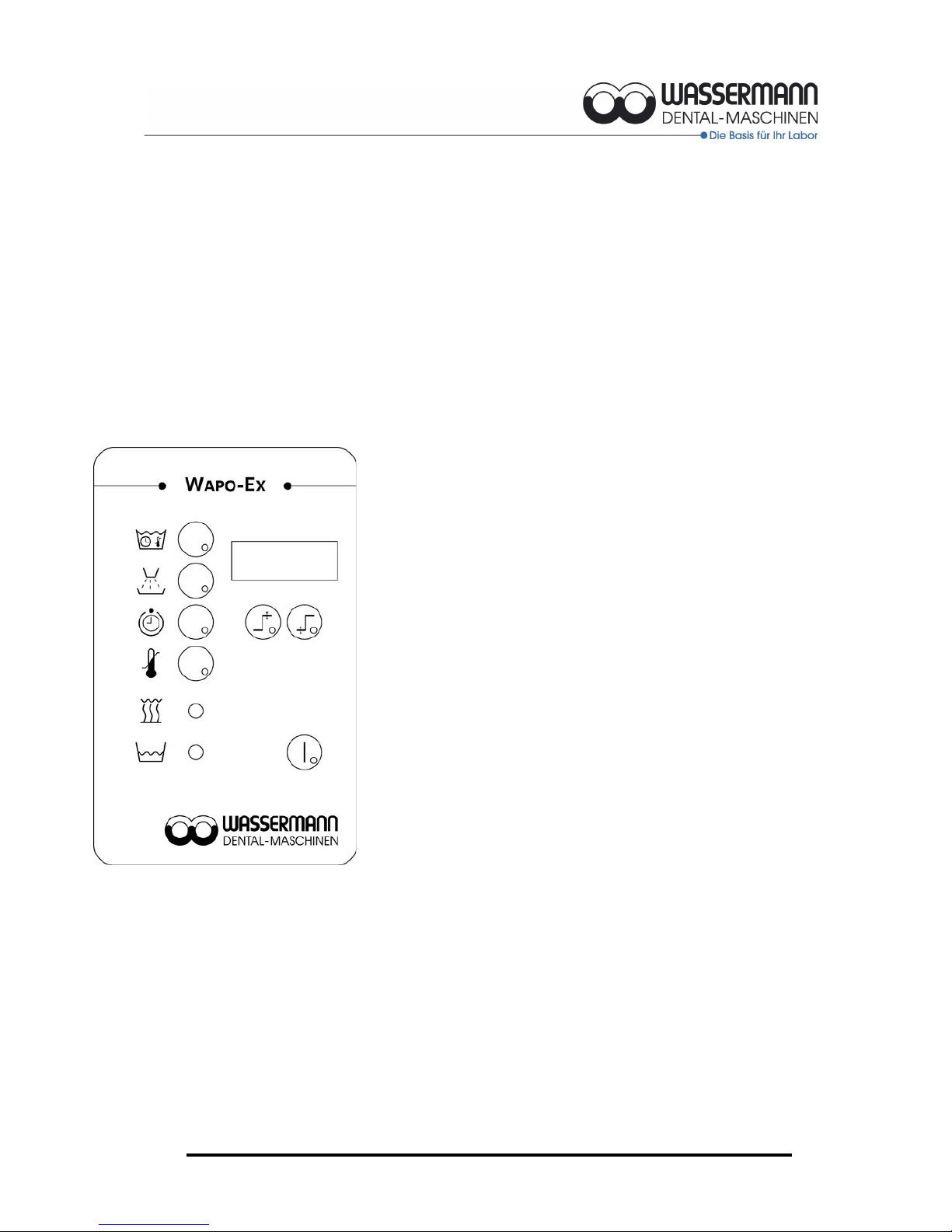

6 Operation.......................................................................................................................7

6.1 Operation.....................................................................................................................7

6.2 Setting time and temperature......................................................................................8

6.2.1 For scalding (button 2).......................................................................................................8

6.2.2 Conversion table °C - °F.....................................................................................................8

6.2.3 Polymerisation (choice of 3 times and 3 temperatures).......................................................9

6.2.4 Setting the time................................................................................................................... 9

6.2.5 Setting the temperature....................................................................................................10

6.3 Storing........................................................................................................................11

6.4 Special function: “Scalding during polymerisation”...................................................11

6.5 Manual operation.......................................................................................................12

7 Troubleshooting / Correcting errors..............................................................................12

8 Maintenance.................................................................................................................14

8.1 Cleaning.....................................................................................................................14

8.2 Maintenance..............................................................................................................15

8.3 Warranty....................................................................................................................15

8.4 Spare parts and accessories.....................................................................................16

8.5 Repairs.......................................................................................................................16

9 Technical data..............................................................................................................17

10 EC CONFORMITY CERTIFICATE.............................................................................18

11 Wiring diagram............................................................................................................19

12 Spare part diagram.....................................................................................................20

Tel.: + 49 (0)40 / 730 926 – 0.................................................................................................1