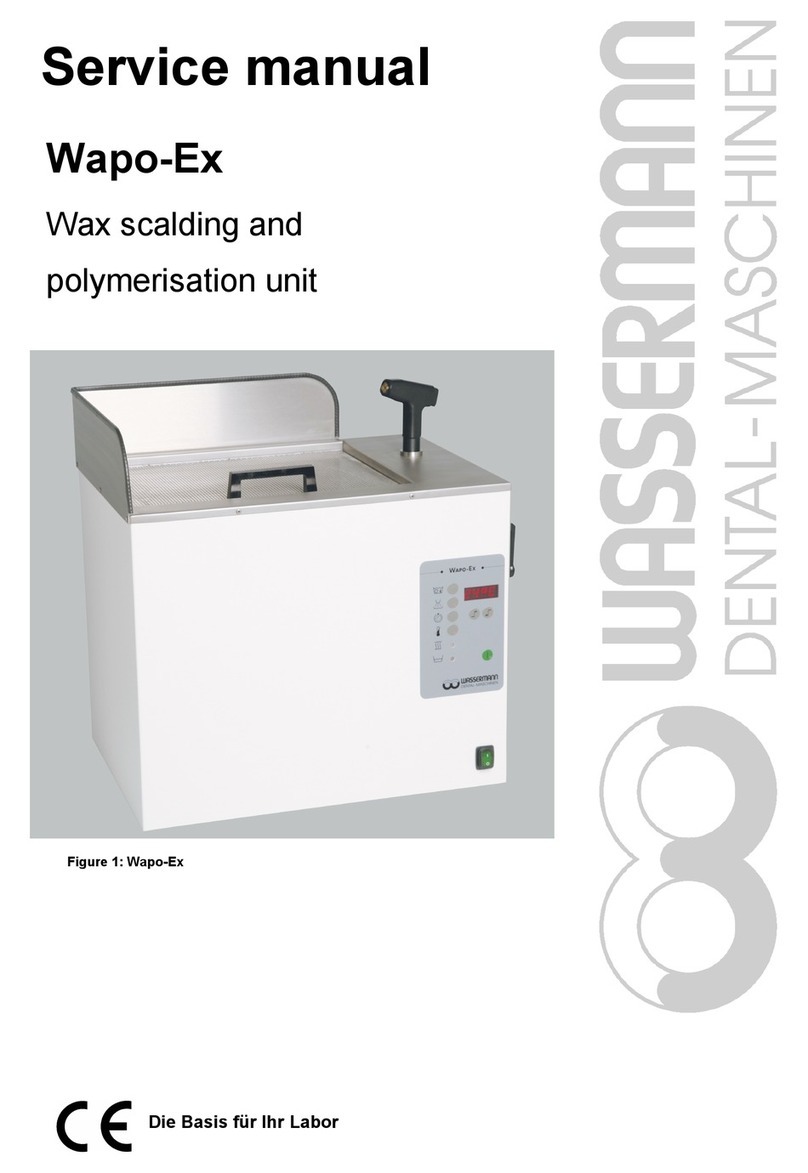

7 Installation/ Start-up

Important!

Never operate the unit without water as the heater climbs immediately to 50°C

as soon as the power comes on

Before starting the unit, connect up the following:

•Connect up a compressed-air supply of at least 3.5 bar If using a long hose, make

sure its ID is at least 6 mm Provide each compressed-air hose with a maintenance

unit and use a regulator to set the pressure to a constant level

Finally, insert the power plug into the socket, making sure that the mains and the unit

operate on the same voltage

7.1 Settin the Correct Pressure

Before filling the container, you should remove the accessory and set the correct

polymerisation pressure To do so:

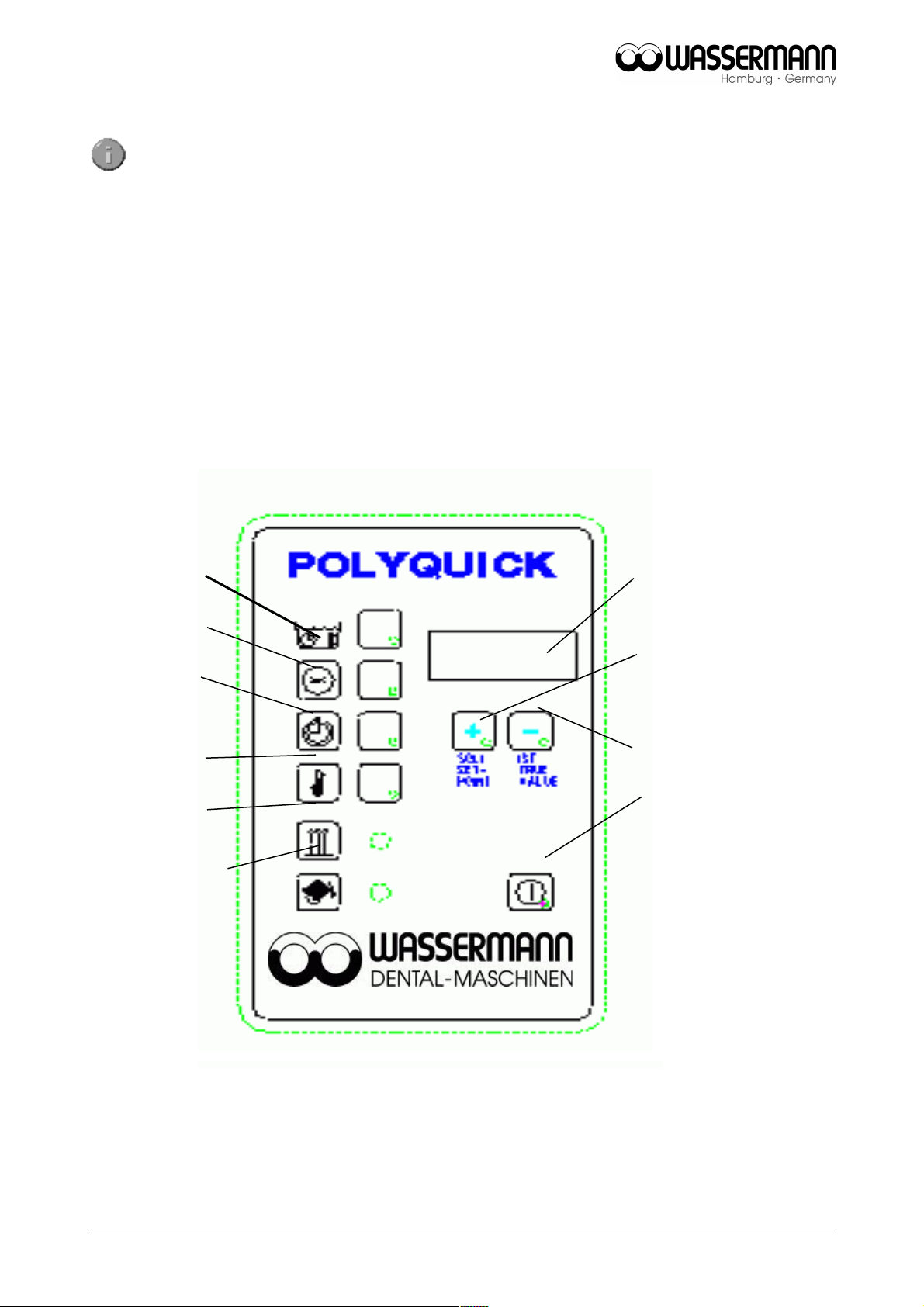

1 Turn on the main switch (green rocker switch)

2 Close the cover and check the door contact (6) control light is on

3 Turn off the heater switch (1); the red LED in the switch will go out

4 Switch on the pressure (2) and the Start/Stop switch (10) containing the red LED

The pressure is preset to 6 bar at the factory.

5 If the pressure is too low (min. 3.5 bar), increase it using the black control at the

rear of the unit (max 6 bar) You have to pull the control out to change it and then

push it in again

6 If the pressure is too hi h, turn off pressure switch (2) and let the pressure reduce

The pressure regulator at the rear of the unit must be turned several times in the

“minus“ direction Then, put the chamber under pressure The desired pressure,

(max. 6 bar), is set by turning the regulator in the “plus“ direction

7 Use the Start/Stop switch (10) to turn the unit off

8