Waterco MultiCyclone Plus User manual

Waterco Limited ABN 62 002 070 733

www.waterco.com

WARNING

(W99279) 11/2010

OFFICES - AUSTRALIA

NSW - Sydney

(HEAD OFFICE)

Tel : +61 2 9898 8686

VIC/ TAS - Melbourne

Tel : +61 3 9764 1211

WA - Perth

Tel : +61 8 9273 1900

QLD - Brisbane

Tel : +61 7 3299 9900

SA/ NT - Adelaide

Tel : +61 8 8244 6000

ACT Distributor

Tel : +61 2 6280 6476

OFFICES - OVERSEAS

Waterco USA

Augusta, USA

Tel : +1 706 793 7291

Waterco Canada

St-Hyacinthe, QC, Canada

Tel : +1 450 796 1421

Waterco (Europe) Limited

Sittingbourne, Kent. UK

Tel : +44(0) 1795 521 733

Waterco (NZ) Limited

Auckland, New Zealand

Tel : +64 9 525 7570

Waterco (C) Limited

Guangzhou, China

Tel : +8620 3222 2180

Waterco (Far East) Sdn. Bhd.

Selangor, Malaysia

Tel : +60 3 6145 6000

PT Waterco Indonesia

Jakarta, Indonesia

Tel : +62 21 4585 1481

Waterco International Pte Ltd

Singapore

Tel : +65 6344 2378

Installation and

Operation Manual

This equipment must be installed and serviced by a qualified technician.

Improper installation may result in property damage, serious injury or death.

Improper installation and/or operation will void the warranty.

Notice to Installer

This manual contains important information about the installation, operation

& safe use of this product. Once the product has been installe this manual

must be given to the owner / operator of this equipment.

Rainbow Pool Products

PO Box 2388, Mansfield Qld 4122

Telephone STD 61-7-3849 5385

Facsimile STD 61-7-3849 5384

Email: [email protected]

Web: www.rainbowpoolproducts.com.au

SAFETY INFORMATION

1. The Waterco MultiCyclone lters are designed to work with water at a temperature > than

0ºC and < than 45ºC. The lter should never be operated outside of these temperatures or

damage may occur.

2. The installation should be carried out in accordance to local safety standards and bylaws.

3. Any modication of the lter requires the prior consent from Waterco. Original replacement

parts and accessories authorised by the manufacturer ensure a high level of safety. Waterco

assumes no liability for the damage and injuries caused by unauthorised replacement parts

and accessories.

4. The user should make sure that the installation is carried out by qualied authorised persons

and that these persons have rst carefully read the following instructions.

5. The operating safety of the lter is only guaranteed if the installation and operation

instructions are correctly followed.

6. In the event of defective operation or fault, contact Waterco or its nearest authorised service

agent.

7. To reduce the risk of injury, do not permit children to use this product.

8. Incorrectly installed equipment may fail, causing severe injury or property damage.

9. Chemical spills and fumes can weaken Swimming Pool / Spa equipment. Corrosion can

cause lters and other equipment to fail, resulting in severe injury or property damage. Do

not store pool chemicals near your equipment.

I pg 02

MultiCyclone Plus

MULTICYCLONE PLUS

MultiCyclone Plus combines centrifugal and cartridge ltration into one streamlined housing,

creating an ultra compact ltration system.

r%VBMTUBHFàMUSBUJPO

r.JOJNBMNBJOUFOBODF

r4BWFXBUFSBOEFOFSHZ

rIZESPDZDMPOFT

rGU2pleated lter cartridge.

Dual stage filtration

Incoming water tangentially enters its multiple

hydrocyclones, generating a strong centrifugal effect.

Approximately 80% of the incoming dirt load is spiralled

down to its clear sediment chamber. The outgoing water

is nally polished via its inbuilt cartridge lter, producing

crystal clear water.

Simple maintenance

MultiCyclone Plus’s sediment chamber is easily cleaned

by opening its purge valve. Only 15 litres of water is

discharged.

Ultra compact filtration

MultiCyclone Plus’s streamlined design means the entire

ltration system can be installed vertically, reducing the

footprint of the equipment pad. Additionally, minimal

pipework reduces ltration system’s overall head loss.

Extended filter capacity

The MultiCyclone Plus’s centrifugal section lter pre-lters

up to 80% of the incoming dirt load before it reaches

the lter cartridge, magnifying the capacity of its 40 ft2

lter cartridge by up to 5 times. MultiCyclone Plus has a

ltration capacity equivalent to a 200 ft2cartridge lter.

SAFTEY INFORMATION ------------------------------------------ 01

MULTICYCLONE PLUS ------------------------------------------- 02

MULTICYCLONE TOTAL HEAD LOSS CURVE ------------------ 04

INSTALLATION ---------------------------------------------------- 04

START UP PROCEEDURES -------------------------------------- 06

MULTICYCLONE PLUS FILTER MAINTENANCE ---------------- 07

INSUFFICIENT WATER PRESSURE ------------------------------ 07

FILTER CARTRIDGE MAINTENANCE ---------------------------- 08

GENERAL MAINTENANCE GUIDE ------------------------------ 09

WINTERISING ----------------------------------------------------- 09

TROUBLESHOOTING GUIDE ------------------------------------ 10

WARRANTY ------------------------------------------------------- 10

SAFETY INFORMATION

1. The Waterco MultiCyclone lters are designed to work with water at a temperature > than

0ºC and < than 45ºC. The lter should never be operated outside of these temperatures or

damage may occur.

2. The installation should be carried out in accordance to local safety standards and bylaws.

3. Any modication of the lter requires the prior consent from Waterco. Original replacement

parts and accessories authorised by the manufacturer ensure a high level of safety. Waterco

assumes no liability for the damage and injuries caused by unauthorised replacement parts

and accessories.

4. The user should make sure that the installation is carried out by qualied authorised persons

and that these persons have rst carefully read the following instructions.

5. The operating safety of the lter is only guaranteed if the installation and operation

instructions are correctly followed.

6. In the event of defective operation or fault, contact Waterco or its nearest authorised service

agent.

7. To reduce the risk of injury, do not permit children to use this product.

8. Incorrectly installed equipment may fail, causing severe injury or property damage.

9. Chemical spills and fumes can weaken Swimming Pool / Spa equipment. Corrosion can

cause lters and other equipment to fail, resulting in severe injury or property damage. Do

not store pool chemicals near your equipment.

I pg 02

MultiCyclone Plus

MULTICYCLONE PLUS

MultiCyclone Plus combines centrifugal and cartridge ltration into one streamlined housing,

creating an ultra compact ltration system.

r%VBMTUBHFàMUSBUJPO

r.JOJNBMNBJOUFOBODF

r4BWFXBUFSBOEFOFSHZ

rIZESPDZDMPOFT

rGU2pleated lter cartridge.

Dual stage filtration

Incoming water tangentially enters its multiple

hydrocyclones, generating a strong centrifugal effect.

Approximately 80% of the incoming dirt load is spiralled

down to its clear sediment chamber. The outgoing water

is nally polished via its inbuilt cartridge lter, producing

crystal clear water.

Simple maintenance

MultiCyclone Plus’s sediment chamber is easily cleaned

by opening its purge valve. Only 15 litres of water is

discharged.

Ultra compact filtration

MultiCyclone Plus’s streamlined design means the entire

ltration system can be installed vertically, reducing the

footprint of the equipment pad. Additionally, minimal

pipework reduces ltration system’s overall head loss.

Extended filter capacity

The MultiCyclone Plus’s centrifugal section lter pre-lters

up to 80% of the incoming dirt load before it reaches

the lter cartridge, magnifying the capacity of its 40 ft2

lter cartridge by up to 5 times. MultiCyclone Plus has a

ltration capacity equivalent to a 200 ft2cartridge lter.

SAFTEY INFORMATION ------------------------------------------ 01

MULTICYCLONE PLUS ------------------------------------------- 02

MULTICYCLONE TOTAL HEAD LOSS CURVE ------------------ 04

INSTALLATION ---------------------------------------------------- 04

START UP PROCEEDURES -------------------------------------- 06

MULTICYCLONE PLUS FILTER MAINTENANCE ---------------- 07

INSUFFICIENT WATER PRESSURE ------------------------------ 07

FILTER CARTRIDGE MAINTENANCE ---------------------------- 08

GENERAL MAINTENANCE GUIDE ------------------------------ 09

WINTERISING ----------------------------------------------------- 09

TROUBLESHOOTING GUIDE ------------------------------------ 10

WARRANTY ------------------------------------------------------- 10

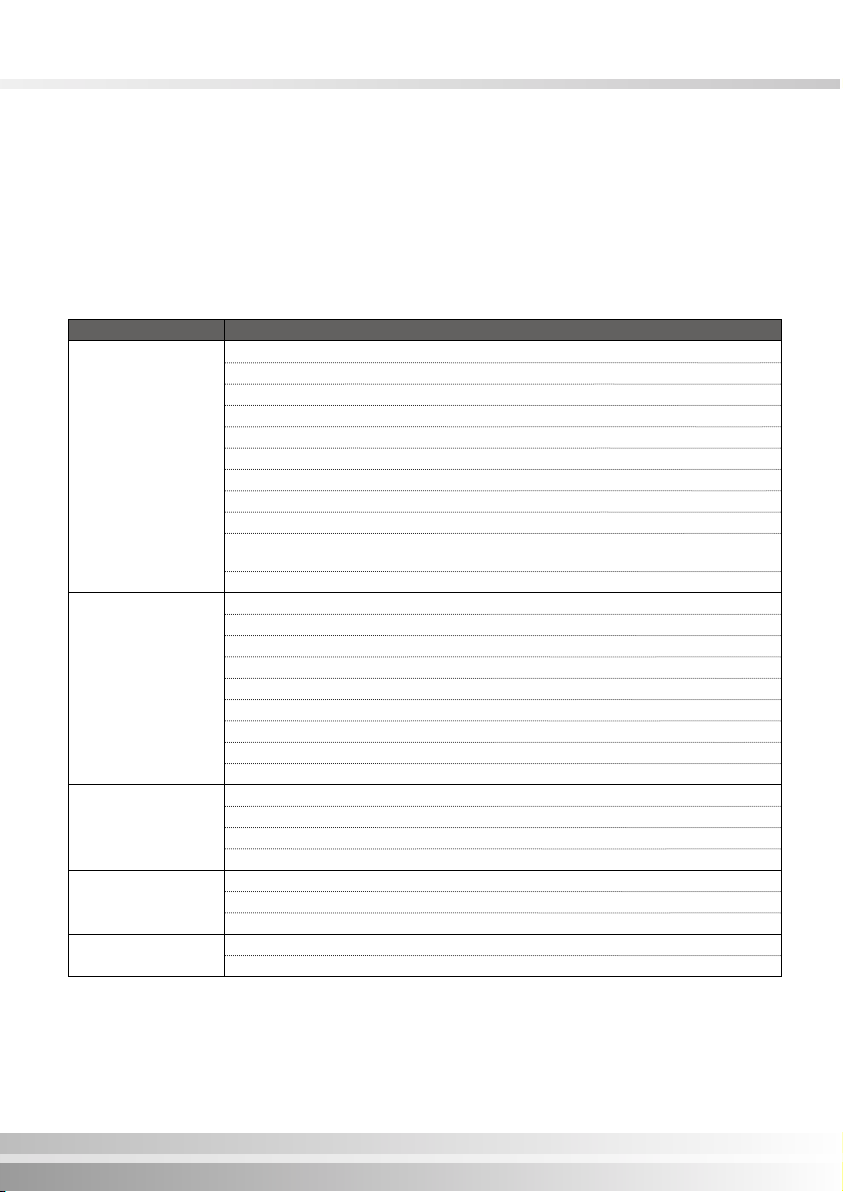

MULTICYCLONE PLUS TOTAL HEAD LOSS CURVE

I pg 04

Note: The MultiCyclone Plus centrifugal section is designed to lter sediment that is heavier

than water; oating debris cannot be ltered out by centrifugal ltration.

INSTALLATION

Be sure to comply with the local plumbing codes.

Be sure that all provisions for wastewater disposal meet local, state or national codes. Do not

discharge water where it will cause ooding or damage.

If the incoming water pressure is higher than the maximum operating pressure of 350kPa /

3.5Bar / 50psi, a Pressure Regulating Valve (PRV) must be installed upstream of the lter inlet.

The PRV should be set to 90% of the maximum operating pressure of the tank.

If the incoming water ow is less than the lter’s minimum ow requirements, the lter’s ltration

efciency will be affected, please consult Waterco.

Model Connection

Ports

Minimum

Flow

Maximum

Flow

Filter

Area

Max.

Pressure

MultiCyclone12

Plus

40mm / 50mm

(EU) / 1 1/2”

40lpm / 2.4 m3/hr

/ 11gpm

152lpm / 9.1 m3/

hr / 40gpm 3.7m2/ 40 ft2350 kPa

(50psi)

MultiCyclone16

Plus

50mm / 63mm

(EU) / 2”

50lpm / 3 m3/hr /

13gpm

152lpm / 9.1 m3/

hr / 40gpm 3.7m2/ 40 ft2350 kPa

(50psi)

Air Release Valve

Filter Cartridge Housing Lid

Filter Housing Retaining Clamp

Band Tightening Nut

Filter Cartridge Housing

Clear Poly Carbonate Sediment

Chamber

Water Flow

12 Plus: 40mm/50mm (EU)

1 ½” Quick Fit Union.

16 Plus: 50mm/63mm (EU)

2” Quick Fit Union.

Pressure Gauge

Filter Housing Retaining Clamp Band

3.7m2/ 40ft2Pleated Filter Cartridge

12 / 16 Hydrocyclones

12 Plus: 40mm/50mm (EU)

1 ½” Quick Fit Union.

16 Plus: 50mm/63mm (EU)

2” Quick Fit Union.

25mm / 32mm (EU)

1” Purge Valve

0

2

4

6

8

10

12

0 50 100 150 200 250 300 350 400

MultiCyclone Plus Total Head Loss Curve

Flow lpm

Head Loss (m)

MultiCyclone 12 Plus MultiCyclone 16 Plus

Typical Installation

1. Position the lter as close to the Swimming Pool / Spa as possible.

2. Position the lter so that it is free from ooding, away from sumps,

guttering, garden hollows, etc.

3. Position the lter so that the piping connections purge valve and air

release valve is convenient and accessible for operation, servicing and

winterising.

4. Ensure that the compliance label is facing the front to allow easy

identication.

MultiCyclone Plus

MULTICYCLONE PLUS TOTAL HEAD LOSS CURVE

I pg 04

Note: The MultiCyclone Plus centrifugal section is designed to lter sediment that is heavier

than water; oating debris cannot be ltered out by centrifugal ltration.

INSTALLATION

Be sure to comply with the local plumbing codes.

Be sure that all provisions for wastewater disposal meet local, state or national codes. Do not

discharge water where it will cause ooding or damage.

If the incoming water pressure is higher than the maximum operating pressure of 350kPa /

3.5Bar / 50psi, a Pressure Regulating Valve (PRV) must be installed upstream of the lter inlet.

The PRV should be set to 90% of the maximum operating pressure of the tank.

If the incoming water ow is less than the lter’s minimum ow requirements, the lter’s ltration

efciency will be affected, please consult Waterco.

Model Connection

Ports

Minimum

Flow

Maximum

Flow

Filter

Area

Max.

Pressure

MultiCyclone12

Plus

40mm / 50mm

(EU) / 1 1/2”

40lpm / 2.4 m3/hr

/ 11gpm

152lpm / 9.1 m3/

hr / 40gpm 3.7m2/ 40 ft2350 kPa

(50psi)

MultiCyclone16

Plus

50mm / 63mm

(EU) / 2”

50lpm / 3 m3/hr /

13gpm

152lpm / 9.1 m3/

hr / 40gpm 3.7m2/ 40 ft2350 kPa

(50psi)

Air Release Valve

Filter Cartridge Housing Lid

Filter Housing Retaining Clamp

Band Tightening Nut

Filter Cartridge Housing

Clear Poly Carbonate Sediment

Chamber

Water Flow

12 Plus: 40mm/50mm (EU)

1 ½” Quick Fit Union.

16 Plus: 50mm/63mm (EU)

2” Quick Fit Union.

Pressure Gauge

Filter Housing Retaining Clamp Band

3.7m2/ 40ft2Pleated Filter Cartridge

12 / 16 Hydrocyclones

12 Plus: 40mm/50mm (EU)

1 ½” Quick Fit Union.

16 Plus: 50mm/63mm (EU)

2” Quick Fit Union.

25mm / 32mm (EU)

1” Purge Valve

0

2

4

6

8

10

12

0 50 100 150 200 250 300 350 400

MultiCyclone Plus Total Head Loss Curve

Flow lpm

Head Loss (m)

MultiCyclone 12 Plus MultiCyclone 16 Plus

Typical Installation

1. Position the lter as close to the Swimming Pool / Spa as possible.

2. Position the lter so that it is free from ooding, away from sumps,

guttering, garden hollows, etc.

3. Position the lter so that the piping connections purge valve and air

release valve is convenient and accessible for operation, servicing and

winterising.

4. Ensure that the compliance label is facing the front to allow easy

identication.

MultiCyclone Plus

I pg 06

5. The lter should be placed on a level concrete slab, very rm ground, or equivalent. Ensure

that the ground will not subside, preventing any strain from the attached plumbing.

6. Ensure that there is no movement of the lter during operation of the purge valve.

7. Allow sufcient clearance around the lter to permit visual inspection of the entire system.

Plumbing

1. Check that the incoming water pressure is within the lter’s recommended working pressure

and ensure that a pressure limiting valve is installed if using mains water or a high pressure

pump.

2. Ensure that a foot valve / non return valve are installed if the pump is installed 500mm / 20”

above the water level.

3. If the lter is installed below the water level or connected to mains water, isolation valves

should be installed at the inlet and outlet of the lter. This will prevent water ow during any

routine maintenance.

4. Minimise the length of pipe and the number of ttings to minimise restrictions to water ow.

5. Ensure that all plumbing connections are glued and tightened securely to prevent leaking.

6. Ensure solvents are not excessively applied to ttings as this could run into “o”-rings and

create sealing problems.

7. Do not over tighten ttings or adapters.

Screw the supplied half barrel unions and tails onto the inlet and outlet before gluing the UPVC

piping onto the lter.

Use only recommended glue for connection pipe and fittings

Cut and t the pipe and ttings onto the MultiCyclone Plus and the pump. Refer to Pump

Installation Manual for correct pump plumbing procedures.

It is best practice to t all the cut pipe and ttings onto the ltration system before gluing; this

will ensure that the system has been aligned correctly.

Glue the pipe and ttings onto the pump, lter and pool return lines and allow the glue to set

for 24 hours before commissioning the system.

Plumbing Connection

1. Connect the pipe extending from the pump outlet to the inlet of the MultiCyclone Plus.

2. Connect from the pipe extending from the outlet of the MultiCyclone Plus to the next

component in line with the ltration system or water return line.

3. Glue all plumbing to barrel union ttings in accordance with glue (solvent) manufactures

specications and allow 24 hours to set. Ensure glue (solvent) is not excessively applied to

ttings as this could run onto “o”-rings and create sealing problems.

Note: Waterco recommends that a shut off valve be installed after the MultiCyclone Plus on

the pool return line to assist with ushing out the collected debris. Please refer to “Insufcient

Water Pressure”.

4. Turn on pool pump. Be sure to check that there are no leaks from the connectors. If required,

tighten by hand.

START UP PROCEEDURES

The MultiCyclone Plus is an advanced and highly efcient lter system that will provide years of

trouble free service if the following maintenance procedures are maintained.

To start up the ltration system either from new or after cleaning is exactly the same.

1. Ensure that the MultiCyclone Plus is plumbed correctly.

2. Ensure that all valves installed before and after the MultiCyclone Plus are open.

3. Loosen the air release valve on top of the MultiCyclone Plus lter lid.

4. Prime the swimming pool pump. (Refer to the pump installation and operation manual).

5. Turn on the swimming pool pump and allow the pump to run until all the air has been expelled

from the MultiCyclone Plus. Water will run from the air release valve.

6. Re-tighten the air release valve.

7. The lter is primed and ready for operation.

Note: In some cases this may be required to be done a few times before the unit will remain

primed and be fully operational.

Do not stand over the lid of the MulitCyclone Plus whilst adjusting the air release valve

to purge the system of air.

Injury may occur if air release valve becomes loose.

MultiCyclone Plus

I pg 06

5. The lter should be placed on a level concrete slab, very rm ground, or equivalent. Ensure

that the ground will not subside, preventing any strain from the attached plumbing.

6. Ensure that there is no movement of the lter during operation of the purge valve.

7. Allow sufcient clearance around the lter to permit visual inspection of the entire system.

Plumbing

1. Check that the incoming water pressure is within the lter’s recommended working pressure

and ensure that a pressure limiting valve is installed if using mains water or a high pressure

pump.

2. Ensure that a foot valve / non return valve are installed if the pump is installed 500mm / 20”

above the water level.

3. If the lter is installed below the water level or connected to mains water, isolation valves

should be installed at the inlet and outlet of the lter. This will prevent water ow during any

routine maintenance.

4. Minimise the length of pipe and the number of ttings to minimise restrictions to water ow.

5. Ensure that all plumbing connections are glued and tightened securely to prevent leaking.

6. Ensure solvents are not excessively applied to ttings as this could run into “o”-rings and

create sealing problems.

7. Do not over tighten ttings or adapters.

Screw the supplied half barrel unions and tails onto the inlet and outlet before gluing the UPVC

piping onto the lter.

Use only recommended glue for connection pipe and fittings

Cut and t the pipe and ttings onto the MultiCyclone Plus and the pump. Refer to Pump

Installation Manual for correct pump plumbing procedures.

It is best practice to t all the cut pipe and ttings onto the ltration system before gluing; this

will ensure that the system has been aligned correctly.

Glue the pipe and ttings onto the pump, lter and pool return lines and allow the glue to set

for 24 hours before commissioning the system.

Plumbing Connection

1. Connect the pipe extending from the pump outlet to the inlet of the MultiCyclone Plus.

2. Connect from the pipe extending from the outlet of the MultiCyclone Plus to the next

component in line with the ltration system or water return line.

3. Glue all plumbing to barrel union ttings in accordance with glue (solvent) manufactures

specications and allow 24 hours to set. Ensure glue (solvent) is not excessively applied to

ttings as this could run onto “o”-rings and create sealing problems.

Note: Waterco recommends that a shut off valve be installed after the MultiCyclone Plus on

the pool return line to assist with ushing out the collected debris. Please refer to “Insufcient

Water Pressure”.

4. Turn on pool pump. Be sure to check that there are no leaks from the connectors. If required,

tighten by hand.

START UP PROCEEDURES

The MultiCyclone Plus is an advanced and highly efcient lter system that will provide years of

trouble free service if the following maintenance procedures are maintained.

To start up the ltration system either from new or after cleaning is exactly the same.

1. Ensure that the MultiCyclone Plus is plumbed correctly.

2. Ensure that all valves installed before and after the MultiCyclone Plus are open.

3. Loosen the air release valve on top of the MultiCyclone Plus lter lid.

4. Prime the swimming pool pump. (Refer to the pump installation and operation manual).

5. Turn on the swimming pool pump and allow the pump to run until all the air has been expelled

from the MultiCyclone Plus. Water will run from the air release valve.

6. Re-tighten the air release valve.

7. The lter is primed and ready for operation.

Note: In some cases this may be required to be done a few times before the unit will remain

primed and be fully operational.

Do not stand over the lid of the MulitCyclone Plus whilst adjusting the air release valve

to purge the system of air.

Injury may occur if air release valve becomes loose.

MultiCyclone Plus

I pg 08

MULTICYCLONE PLUS FILTER MAINTENANCE

The MultiCyclone Plus lter maintenance is determined by the following conditions:

1. The sediment chamber is half lled with sediment. This accumulation of sediment can be

visibly monitored through the MultiCyclone Plus’s clear sediment chamber. The MultiCyclone

Plus is cleaned by simply opening the purge valve. Only 15 litres (4 gallons) of water is

discharged to clean the MultiCyclone of sediment.

2. A pressure gauge reading of 50kPa (7.2psi) above the operating pressure may result in a

reduced ow rate that is insufcient to meet the requirements of the pool.

Example: Filter operates normally at 60kPa (8.2psi) needs to be cleaned at 110kPa (16psi).

Flush out the sediment chamber

With pump running:

Whilst the water pump is running simply open the sediment purge valve until the sediment has

been ushed out. This is visible through the clear sediment chamber. Once the sediment has

been ushed out, close the purge valve.

Without pump running:

Alternatively, switch the pump, off. Open the air release valve and then open the purge valve.

The water will drop through the MultiCyclone Plus ushing out most of the debris from the

sediment chamber. Then close the air release valve and turn on the pump and the turbulence

of the water entering the sediment chamber will ush out the rest of the sediment. Once the

sediment chamber has been cleansed, close the purge valve, start the pump and close the air

release valve once water is owing out through the air release valve.

INSUFFICIENT WATER PRESSURE

In situations where the water ow from the pump is not powerful enough purge the sediment

out of the sediment chamber. Waterco recommends tting a 2 way valve after the MultiCyclone

Plus on the pool water return line.

The 2 way valve is used to throttle the ow of water out of the MultiCyclone Plus, increasing

water turbulence through the sediment chamber and improving its purging action.

Whilst the pump is operating, open the purge valve, and then partially close the 2 way valve,

throttling the water ow sufciently to purge the sediment chamber of trapped sediment. Once

the sedimement chamber is clean, open the 2 way valve and then close the purge valve.

Do not close the 2 way valve prior to opening the purge valve and do not close the purge

valve while the 2 way valve is closed or partially closed. Both valves should never be

closed or partially closed at the same time.

FILTER CARTRIDGE MAINTENANCE

To ensure maximum life from your MultiCyclone Plus’s lter cartridge you need to maintain the

lter cartridge regularly.

When the lter is rst started and has been purged of air, note the pressure on the pressure

gauge. This is what is known as the lter operating pressure and it is important that you be

aware of this gure.

All ltration systems will operate at different pressures depending on the pool hydraulics.

You will need to clean the lter cartridge once the pressure gauge has reached 50kPa (7.2psi)

above the operating pressure.

Example: Filter operates normally at 60kPa (8.2psi) needs to be cleaned at

110kPa (16psi).

Cartridge Cleaning

Prior to removing the MultiCyclone Plus cartridge lter’s lid, you will need to release the pressure

from the lter cartridge housing. With the pump off, loosen the air release valve on top of the

MultiCyclone Plus lter lid to release pressure from the lter housing.

1. Undo and remove the clamp around the cartridge lter’s lid by unscrewing the tightening

nuts, this can be either by hand or using a 25mm (1”) open end spanner/adjustable wrench

on the moulded hexagon section and remove the lid off the lter tank.

2. Remove the lter cartridge from the lter housing.

3. Using a garden type hose clean the surface of the pleated element. Make sure to clean

between the pleats.

4. Place the lter cartridge back into the lter housing ensuring that it is seated correctly.

5. Ensure the lid “o”-ring is clean of any debris and is correctly seated into lter body “o”-ring

groove prior to lid being retted.

6. Place the lid onto the lter housing and ret retaining clamp band and tightening nuts using

a 25mm (1”) open end spanner/adjustable wrench ensuring lid is correctly tted.

7. Refer to the start up procedure to recommence operation.

MultiCyclone Plus

Do not over tighten the lid tightening nuts.

I pg 08

MULTICYCLONE PLUS FILTER MAINTENANCE

The MultiCyclone Plus lter maintenance is determined by the following conditions:

1. The sediment chamber is half lled with sediment. This accumulation of sediment can be

visibly monitored through the MultiCyclone Plus’s clear sediment chamber. The MultiCyclone

Plus is cleaned by simply opening the purge valve. Only 15 litres (4 gallons) of water is

discharged to clean the MultiCyclone of sediment.

2. A pressure gauge reading of 50kPa (7.2psi) above the operating pressure may result in a

reduced ow rate that is insufcient to meet the requirements of the pool.

Example: Filter operates normally at 60kPa (8.2psi) needs to be cleaned at 110kPa (16psi).

Flush out the sediment chamber

With pump running:

Whilst the water pump is running simply open the sediment purge valve until the sediment has

been ushed out. This is visible through the clear sediment chamber. Once the sediment has

been ushed out, close the purge valve.

Without pump running:

Alternatively, switch the pump, off. Open the air release valve and then open the purge valve.

The water will drop through the MultiCyclone Plus ushing out most of the debris from the

sediment chamber. Then close the air release valve and turn on the pump and the turbulence

of the water entering the sediment chamber will ush out the rest of the sediment. Once the

sediment chamber has been cleansed, close the purge valve, start the pump and close the air

release valve once water is owing out through the air release valve.

INSUFFICIENT WATER PRESSURE

In situations where the water ow from the pump is not powerful enough purge the sediment

out of the sediment chamber. Waterco recommends tting a 2 way valve after the MultiCyclone

Plus on the pool water return line.

The 2 way valve is used to throttle the ow of water out of the MultiCyclone Plus, increasing

water turbulence through the sediment chamber and improving its purging action.

Whilst the pump is operating, open the purge valve, and then partially close the 2 way valve,

throttling the water ow sufciently to purge the sediment chamber of trapped sediment. Once

the sedimement chamber is clean, open the 2 way valve and then close the purge valve.

Do not close the 2 way valve prior to opening the purge valve and do not close the purge

valve while the 2 way valve is closed or partially closed. Both valves should never be

closed or partially closed at the same time.

FILTER CARTRIDGE MAINTENANCE

To ensure maximum life from your MultiCyclone Plus’s lter cartridge you need to maintain the

lter cartridge regularly.

When the lter is rst started and has been purged of air, note the pressure on the pressure

gauge. This is what is known as the lter operating pressure and it is important that you be

aware of this gure.

All ltration systems will operate at different pressures depending on the pool hydraulics.

You will need to clean the lter cartridge once the pressure gauge has reached 50kPa (7.2psi)

above the operating pressure.

Example: Filter operates normally at 60kPa (8.2psi) needs to be cleaned at

110kPa (16psi).

Cartridge Cleaning

Prior to removing the MultiCyclone Plus cartridge lter’s lid, you will need to release the pressure

from the lter cartridge housing. With the pump off, loosen the air release valve on top of the

MultiCyclone Plus lter lid to release pressure from the lter housing.

1. Undo and remove the clamp around the cartridge lter’s lid by unscrewing the tightening

nuts, this can be either by hand or using a 25mm (1”) open end spanner/adjustable wrench

on the moulded hexagon section and remove the lid off the lter tank.

2. Remove the lter cartridge from the lter housing.

3. Using a garden type hose clean the surface of the pleated element. Make sure to clean

between the pleats.

4. Place the lter cartridge back into the lter housing ensuring that it is seated correctly.

5. Ensure the lid “o”-ring is clean of any debris and is correctly seated into lter body “o”-ring

groove prior to lid being retted.

6. Place the lid onto the lter housing and ret retaining clamp band and tightening nuts using

a 25mm (1”) open end spanner/adjustable wrench ensuring lid is correctly tted.

7. Refer to the start up procedure to recommence operation.

MultiCyclone Plus

Do not over tighten the lid tightening nuts.

I pg 10

It is suggested that you should periodically remove the lter cartridge and soak it over night in

a suitable cartridge cleaning compound. This will remove any debris not removed by hosing

down of the lter cartridge.

Some swimming pool stores offer a lter cartridge cleaning service using the correct solutions

otherwise you may wish to use Waterco Cartridge cleaning solution. Directions of use are on

the product.

The cleaning time depends upon the swimming pool condition and use. Intervals between

cleaning the element should not exceed a period of 12 months in any instance.

GENERAL MAINTENANCE GUIDE

To ensure the maximum life of the MultiCyclone Plus, please follow the procedures below:

1. Clean the lter cartridge regularly according to the instructions set under “MultiCyclone Filter

Cartridge”

2. Maintain a correct chemical balance of your pool / spa water. The chemical balance of water

is a relationship between its pH, total alkalinity, calcium hardness and water temperature.

The water must be maintained at all times to the following:

PH LEVEL : BETWEEN 7.2 & 7.8.

TOTAL ALKALINITY : BETWEEN 80 & 150ppm.

CALCIUM HARDNESS : BETWEEN 150 & 300ppm.

Also, within these tolerances be balanced to the Langelier Saturation Index within a range of

-0.2 to +0.2.

Note: Testing kits are available to test the water yourself or alternately bring a sample of the

water to a professional pool and spa shop.

3. Mains water and rural water supplies need to be monitored. Saturation (life) in mains water

or bore (rural) will vary depending on water quality.

4. To prevent damage to the pump and lter and for proper operation of the system, clean

pump strainer and skimmer baskets regularly.

5. Replace the pressure gauge if faulty readings are observed.

WINTERISING

Proper winterising procedures should always be taken in order to protect your lter in cold

climates (temperatures below freezing point).

1. Switch off the Pump / Close the inlet valve.

TROUBLESHOOTING GUIDE

WARRANTY

MultiCyclone Plus is covered by a 2 year warranty and 1 year warranty on labour. Commercial

installations are covered by a 1 year warranty.

Please refer to Waterco’s warranty terms and conditions.

Symptoms Possible Problems / Solutions

Water Is Not Clear

Insufcient disinfectant level.

Incorrect pool chemistry.

Heavy bathing and/ or dirt loads.

Incorrect ow.

Insufcient running times. (Increase pump run time.)

Filter is dirty. (Clean per instructions.)

Hole in lter element.

Air leak on suction line

Pump impeller vanes blocked

Other restrictions include (pool suction cleaners) resistance from other inline

equipment such as strainers.

Pump not primed.

Low Water Flow

Check strainer baskets for debris.

Check for air leaks on suction side.

Check for restrictions or blockage in either suction or return lines.

Filter needs to be cleaned or replaced.

Pool water level too low.

Pump not primed.

Pump impeller vanes blocked.

Strainer baskets not being used and/ or not being cleaned regularly.

Pump operating under speed (low voltage).

Short Filter Cycles

Presence of algae, check disinfectant content.

Check pH and total alkalinity.

Pump output exceeds design ow rate of lter, check pump performance.

Ineffective cleaning, check conditions, replace lter cartridge.

High Pressure on

Start Up

Small eyeball tting in Pool/ Spa.

Partially closed valve on return line.

Too large of pump, check selection.

Dirt Returns to Pool Hole in lter cartridge, replace lter cartridge.

Worn “o”-ring seal inside lter, replace o-ring.

2. Open the air release valve and open the purge vale to allow water to ow out of the

MultiCyclone Plus.

3. Remove any drain plugs from the pump.

4. Drain water from the pipe work.

MultiCyclone Plus

I pg 10

It is suggested that you should periodically remove the lter cartridge and soak it over night in

a suitable cartridge cleaning compound. This will remove any debris not removed by hosing

down of the lter cartridge.

Some swimming pool stores offer a lter cartridge cleaning service using the correct solutions

otherwise you may wish to use Waterco Cartridge cleaning solution. Directions of use are on

the product.

The cleaning time depends upon the swimming pool condition and use. Intervals between

cleaning the element should not exceed a period of 12 months in any instance.

GENERAL MAINTENANCE GUIDE

To ensure the maximum life of the MultiCyclone Plus, please follow the procedures below:

1. Clean the lter cartridge regularly according to the instructions set under “MultiCyclone Filter

Cartridge”

2. Maintain a correct chemical balance of your pool / spa water. The chemical balance of water

is a relationship between its pH, total alkalinity, calcium hardness and water temperature.

The water must be maintained at all times to the following:

PH LEVEL : BETWEEN 7.2 & 7.8.

TOTAL ALKALINITY : BETWEEN 80 & 150ppm.

CALCIUM HARDNESS : BETWEEN 150 & 300ppm.

Also, within these tolerances be balanced to the Langelier Saturation Index within a range of

-0.2 to +0.2.

Note: Testing kits are available to test the water yourself or alternately bring a sample of the

water to a professional pool and spa shop.

3. Mains water and rural water supplies need to be monitored. Saturation (life) in mains water

or bore (rural) will vary depending on water quality.

4. To prevent damage to the pump and lter and for proper operation of the system, clean

pump strainer and skimmer baskets regularly.

5. Replace the pressure gauge if faulty readings are observed.

WINTERISING

Proper winterising procedures should always be taken in order to protect your lter in cold

climates (temperatures below freezing point).

1. Switch off the Pump / Close the inlet valve.

TROUBLESHOOTING GUIDE

WARRANTY

MultiCyclone Plus is covered by a 2 year warranty and 1 year warranty on labour. Commercial

installations are covered by a 1 year warranty.

Please refer to Waterco’s warranty terms and conditions.

Symptoms Possible Problems / Solutions

Water Is Not Clear

Insufcient disinfectant level.

Incorrect pool chemistry.

Heavy bathing and/ or dirt loads.

Incorrect ow.

Insufcient running times. (Increase pump run time.)

Filter is dirty. (Clean per instructions.)

Hole in lter element.

Air leak on suction line

Pump impeller vanes blocked

Other restrictions include (pool suction cleaners) resistance from other inline

equipment such as strainers.

Pump not primed.

Low Water Flow

Check strainer baskets for debris.

Check for air leaks on suction side.

Check for restrictions or blockage in either suction or return lines.

Filter needs to be cleaned or replaced.

Pool water level too low.

Pump not primed.

Pump impeller vanes blocked.

Strainer baskets not being used and/ or not being cleaned regularly.

Pump operating under speed (low voltage).

Short Filter Cycles

Presence of algae, check disinfectant content.

Check pH and total alkalinity.

Pump output exceeds design ow rate of lter, check pump performance.

Ineffective cleaning, check conditions, replace lter cartridge.

High Pressure on

Start Up

Small eyeball tting in Pool/ Spa.

Partially closed valve on return line.

Too large of pump, check selection.

Dirt Returns to Pool Hole in lter cartridge, replace lter cartridge.

Worn “o”-ring seal inside lter, replace o-ring.

2. Open the air release valve and open the purge vale to allow water to ow out of the

MultiCyclone Plus.

3. Remove any drain plugs from the pump.

4. Drain water from the pipe work.

MultiCyclone Plus

Table of contents

Other Waterco Swimming Pool Filter manuals

Popular Swimming Pool Filter manuals by other brands

SACOPA

SACOPA 30889 Installation and maintenance manual

Davey

Davey PoolSweepa FloorCova operating instructions

Steinbach

Steinbach 040590 instruction manual

Aqua Comfort Technologies

Aqua Comfort Technologies Auto-Chlor AC-4000 owner's manual

BLAU aquaristic

BLAU aquaristic Scuma MKB Series user guide

Jandy Pro Series

Jandy Pro Series TruClear Installation and operation manual