Q: Where is the system installed?

Typically, the system is installed under the kitchen sink. Some homeowners or installers prefer the

basement or crawlspace, as this conserves storage in the kitchen and may allow for easier access

to the system for maintenance purposes.

If you install the system more that 20’ from your faucet, you may need a product water booster

pump to ensure adequate pressure at the faucet. Your dealer can provide you with this optional

equipment.

Q: Can the Vectapure II™ system be connected to an extra faucet?

Yes. Many installations will include an optional ¼” line to refrigerator icemakers or additional sink

faucets. See your dealer for advice and parts.

Q: What factors affect the quantity and the quality of the water produced?

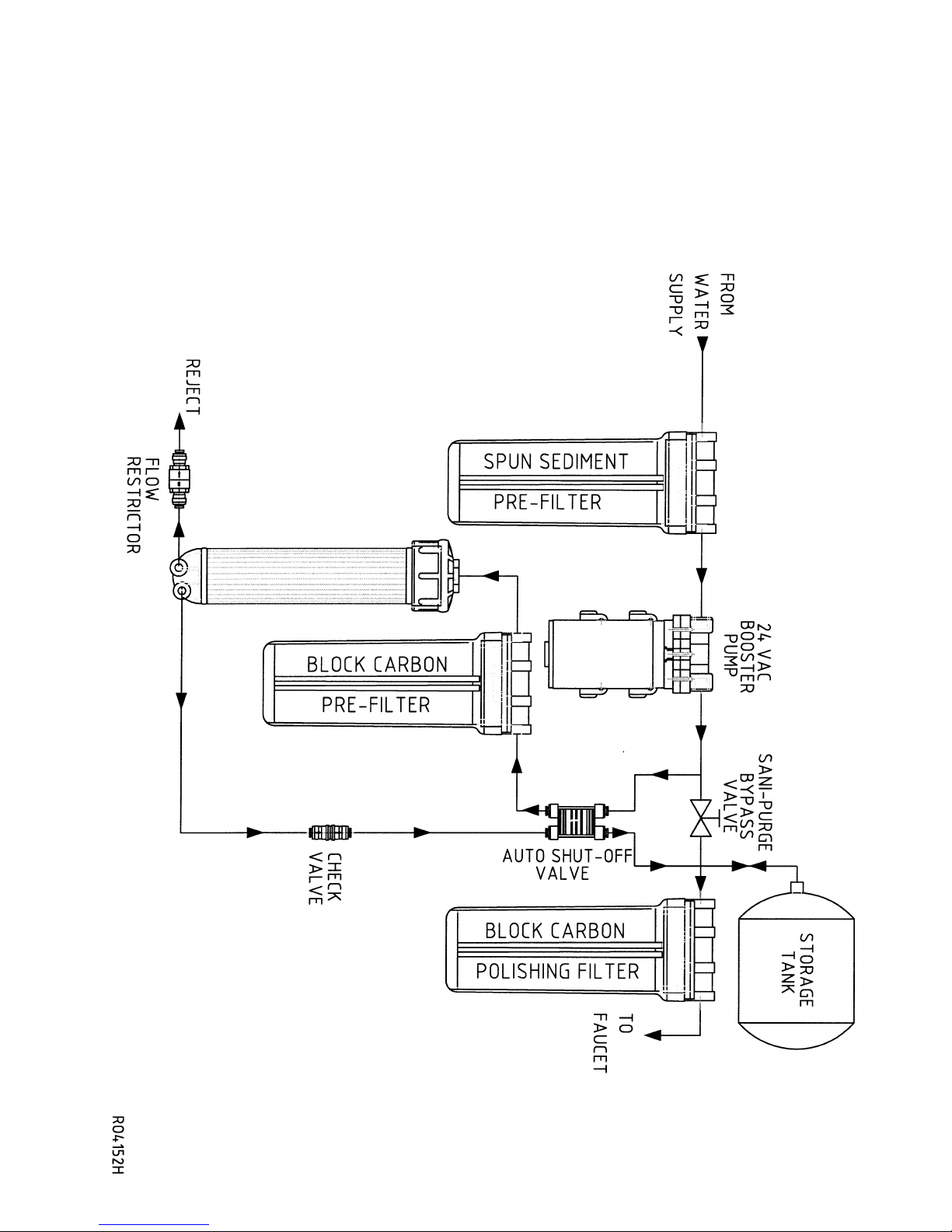

1. Pressure: The greater the water system pressure, the greater the water quantity that will be

produced. 60PSI is optimal, but it should never exceed 90PSI. Where water pressures are

low (<40PSI), a booster pump on the raw water line can be added to increase production.

The RO-4152H comes equipped with a booster pump as standard equipment.

2. Temperature: Production increases with temperature, the optimal being 76F. Never

operate the system from the hot water line or with water exceeding 85F, as this will

damage the membrane.

3. Membrane type: Vectapure II systems use premium quality TFC (Thin Film Composite)

membranes, specially chosen for household applications.

4. TDS: The higher the Total Dissolved Solids in the raw water, the lower the output of

product water. Booster pumps are used to increase system pressure and overcome lower

output caused by higher TDS. System pressure may not however, exceed 90PSI.

Q: How much water does the Vectapure II™ system produce?

All Vectapure™ systems use membranes nominally rated for 75GPD. Actual output will be

dependent upon the factors explained above. In optimal applications (with a booster pump) you

may expect 60-70 gallons to be available over 24 hours.

Q: Can the amount of water produced be increased?

Filling a water pitcher for the refrigerator will allow more production overnight. A larger holding

tank (available from your dealer) will allow for more water to be on hand. Booster pumps will also

increase daily production.

Q: What is the standard warranty with the Vectapure II™ system?

Every Vectapure II™ system comes with a standard one-year limited warranty on all parts and

repair labour. A detailed warranty card is included with the unit. You may purchase and

extended warranty if you wish - see the enclosed Extended Warranty Program information

sheet and enrolment form included in your package. Call your dealer if you wish to have

one sent to you. Normal filter cartridge replacement is excluded from your warranty.

Q: What is the maintenance schedule for the Vectapure II™ system?

A good rule of thumb is to replace all pre-filters every three months. This is critical to ensure that

chlorine does not attack the membrane film. The carbon post-filter should be changed every three

to six months. When the old cartridges have been removed, the system should be purged and

flooded with chlorinated water before the new cartridges are installed. Dependent upon local

water conditions, your membrane should have a life expectancy of 1-5 years. More severe water

conditions (iron, hardness) may shorten this significantly; soft water sources may allow a

membrane life of up to 8 years.